Drainage pipe docking device and docking method

A technology of docking device and drainage pipeline, applied in the direction of tubular objects, household appliances, other household appliances, etc., can solve the problems of deformation of the outer wall of the pipeline, easy damage of the pipeline, affecting the subsequent use of the pipeline, etc., so as to improve the quality and integrity of the docking. , Improve the effect of docking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The application will be described in further detail below in conjunction with the accompanying drawings.

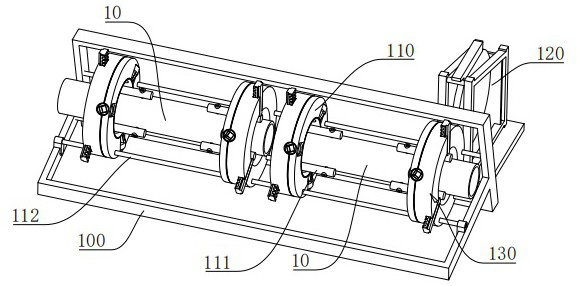

[0046] The embodiment of the present application discloses a drainage pipe butt joint device, referring to figure 1 , including a base 100, a sliding frame 110 arranged on the base 100, and a hot-melt structure 120 arranged on the base 100, the sliding frame 110 is used to position the pipeline 10, and then passes through the hot-melt structure 120 to the pipeline 10 after sliding The ends are heated and melted to finally realize the butt joint of the pipes 10 .

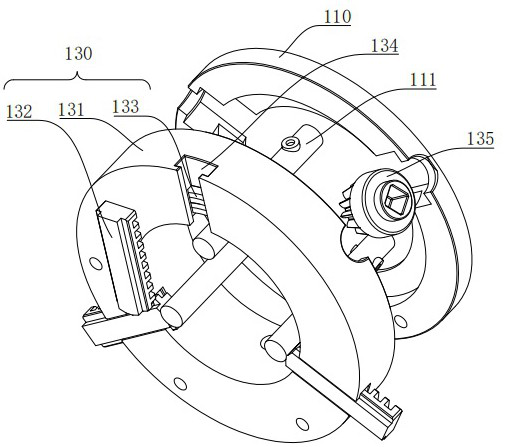

[0047] In this embodiment, the sliding frame 110 is ring-shaped, and the middle of the sliding frame 110 is used to pass through the pipeline 10. The sliding frame 110 is provided with positioning round rods for limiting the position of the pipeline 10 in the circumferential direction and the axial direction at the same time. 111, the ring surface where the sliding frame 110 is located is vertically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com