Technology method for section steel butting and centering clamp

A process method and section steel technology, which is applied in the fields of steel product processing, machinery manufacturing, and steel structure manufacturing, can solve problems such as quality defects, difficulty in ensuring the centering of section steel, easy occurrence of misalignment, and bending, etc., so as to improve the quality of butt joints and ensure smoothness Straightness, effect of labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

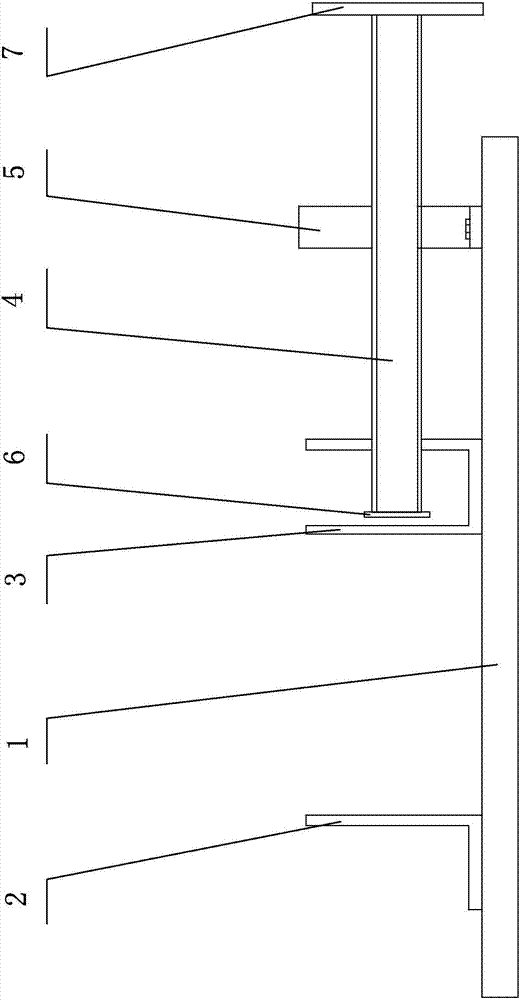

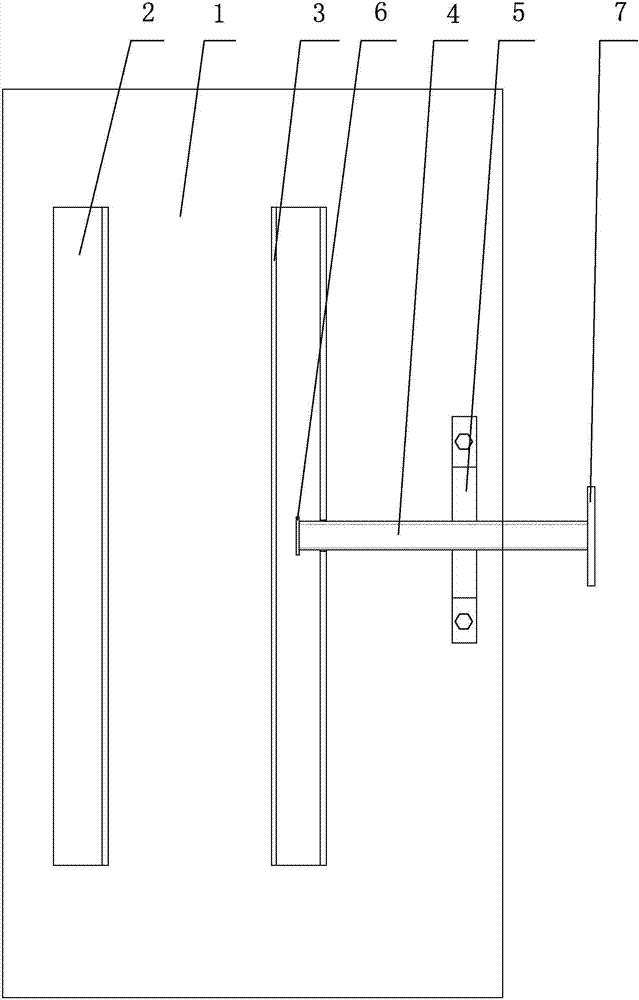

[0024] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0025] The technological method of the butt-joint centering jig of the section steel of the present invention comprises the manufacturing process of the butt-joint centering jig of the section steel and the centering process of the butt-joint centering jig of the section steel.

[0026] The steel butt joint centering fixture includes the transmission mechanism composed of the operating platform 1, the angle steel 2, the channel steel 3 and the screw nut, and its manufacturing process is as follows:

[0027] The horizontal angle steel 2 and channel steel 3 in the left and right direction are set on the operation platform 1 front and back, the angle steel 2 (notch forward and upward) is spot welded on the operation platform 1, and the channel steel 3 (notch upward) is placed on the The operating platform 1 or the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com