Corrugated pipe butt joint device

A technology of docking device and bellows, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of poor mutual docking effect of bellows and the deviation of bellows, so as to achieve high work efficiency, prevent damage to bellows, and improve the quality of butt joints. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

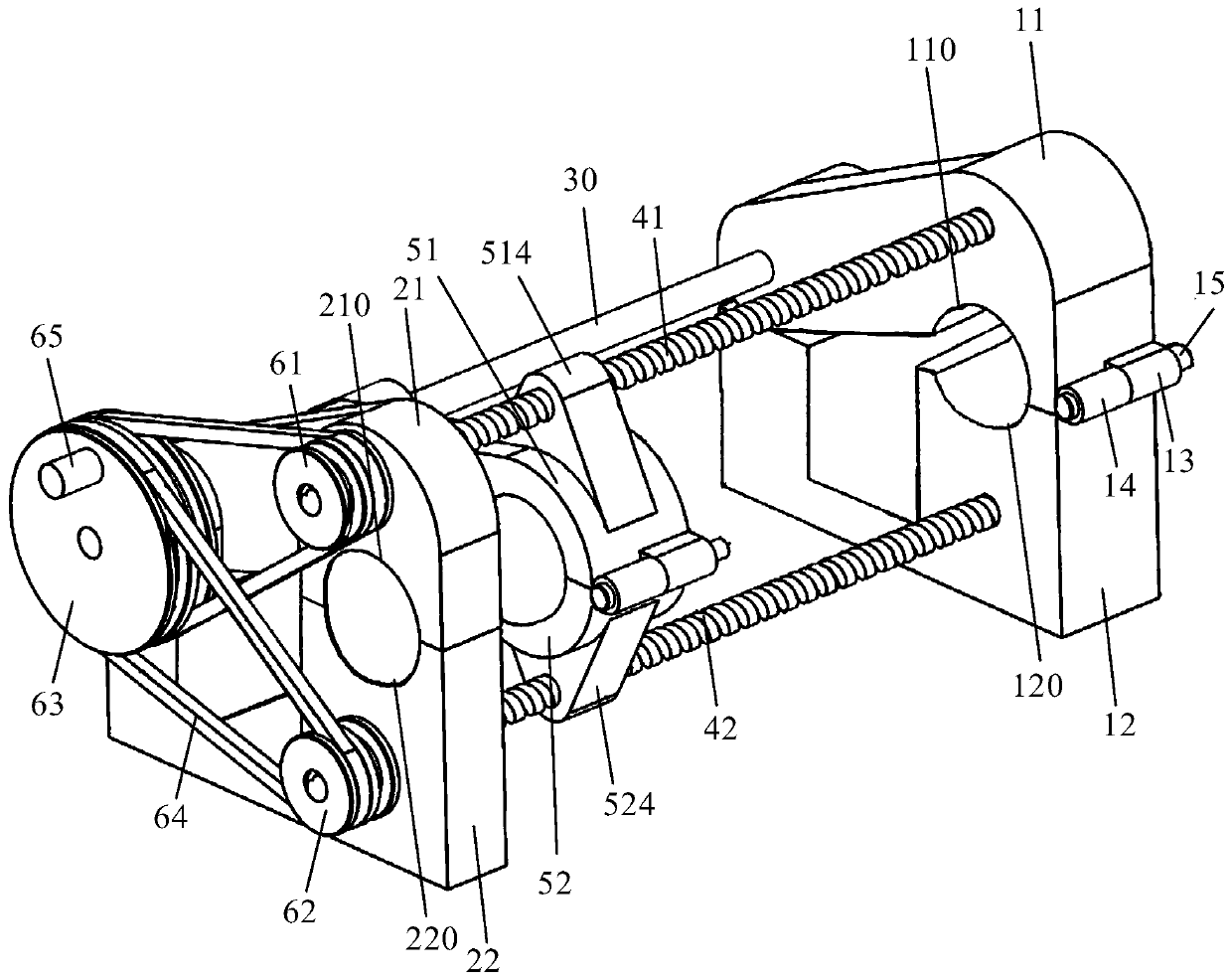

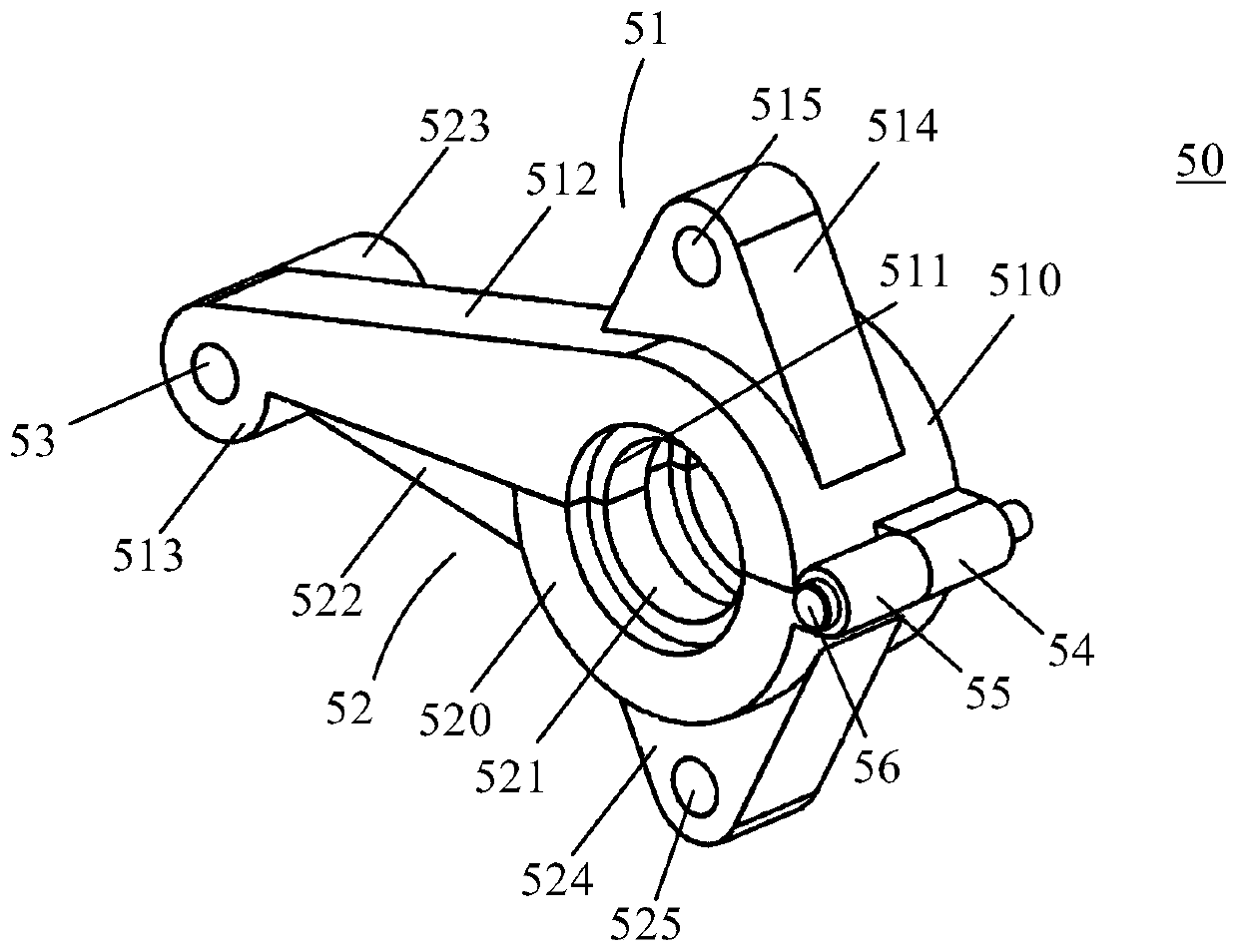

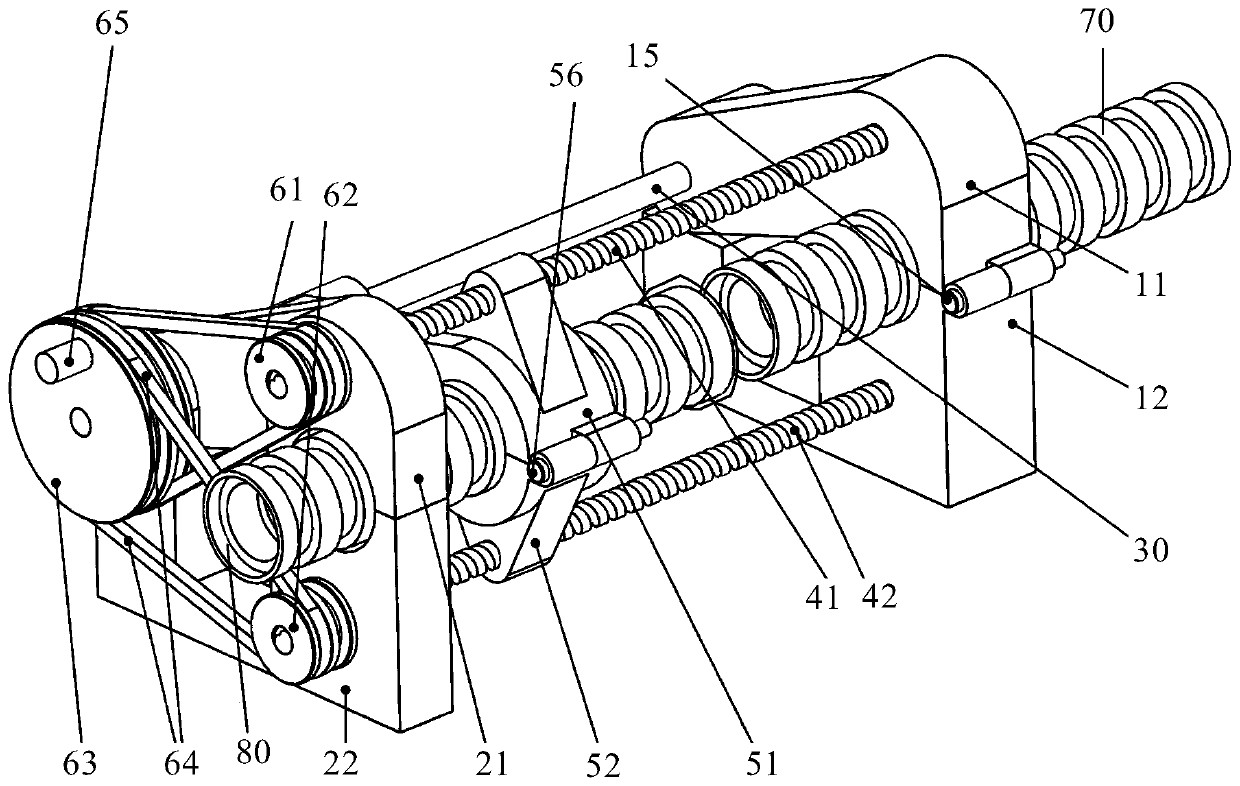

[0013] Such as Figure 1 to Figure 5 As shown, the corrugated pipe docking device of the present invention includes a lower fixing base 12 placed on the ground, a lower supporting base 22, and a docking buckle mechanism 50 suspended between the lower fixing base 12 and the lower supporting base 22, the docking buckle Mechanism 50 comprises lower buckle 52, wherein: the top of lower fixing base 12, lower support base 22, lower buckle 52 is respectively rotatably installed with upper fixing base 11, upper supporting base 21, upper buckle through the same optical rod 30. 51; one end of the upper lead screw 41 is rotatably connected to the upper fixed seat 11, and the other end of the upper lead screw 41 is rotatably connected to the upper driven pulley 61 after passing through the upper buckle 51 and the upper support seat 21; One end of the leading screw 42 is rotatably connected with the lower fixing seat 12, and the other end of the lower leading screw 42 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com