power unit for pipe jacking

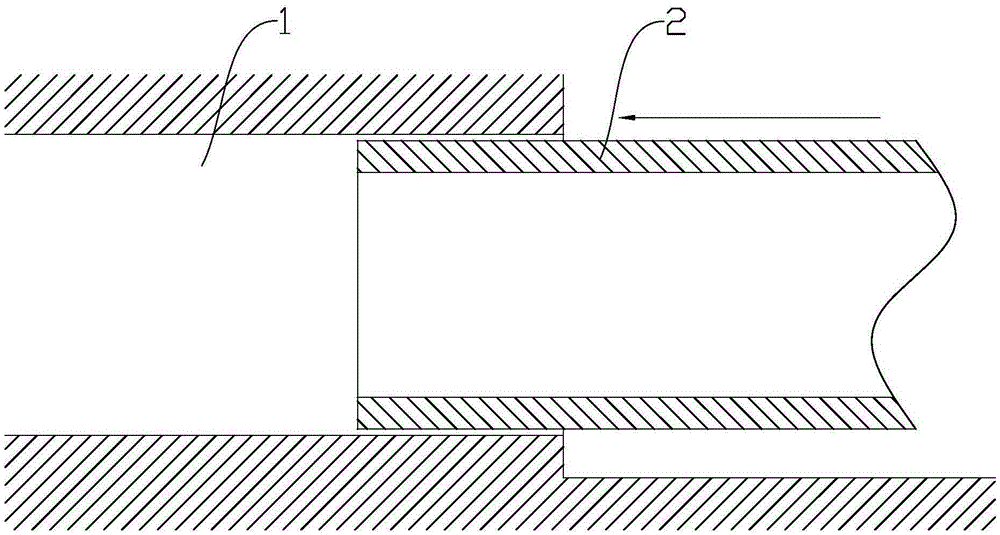

A power device and practical technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of poor quality of pipeline butt joints, inability to complete pipeline laying quickly and smoothly, and easy deviation of pipelines, etc. , to achieve the effect of improving the docking quality, preventing being stuck, and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

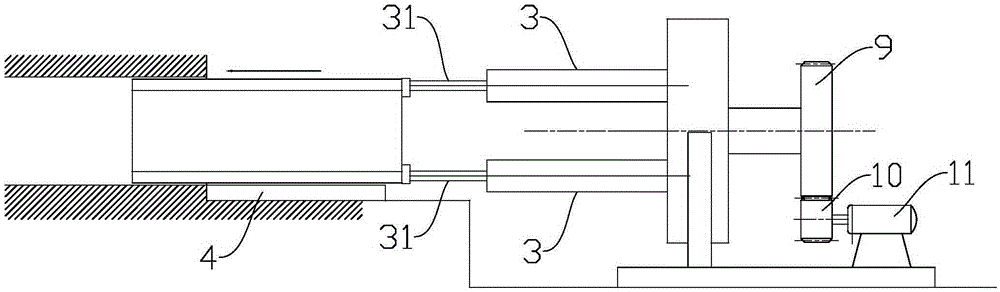

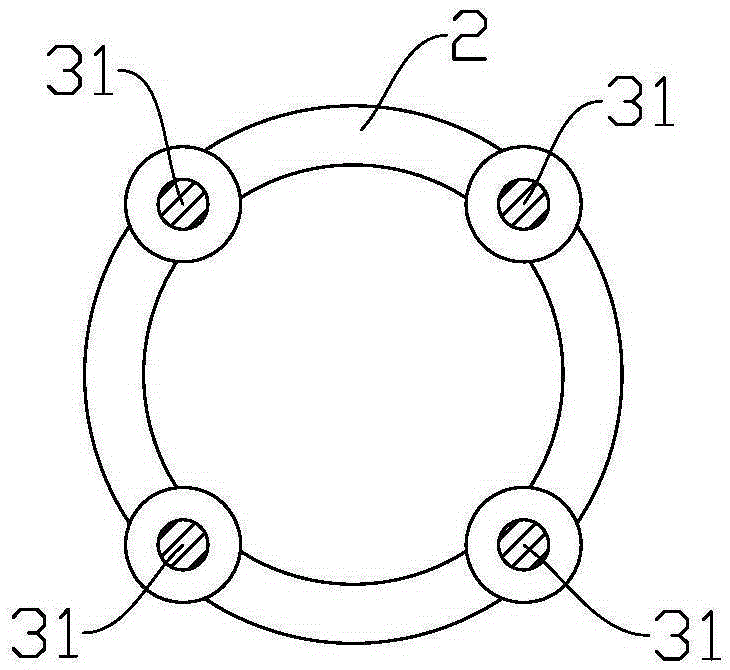

[0014] Such as Figure 2-4 As shown, the power device for pipe jacking mainly includes a jack 3 and a support for supporting the jack.

[0015] Wherein said jack 3 is provided with four, and the specification of four jacks is exactly the same. The rear end coaxial line of each jack 3 is fixed with a pinion gear 5; the parameters of the four pinion gears 5 are equal and all mesh with a central bull gear 6, and the four pinion gears 5 are evenly arranged around the axis of the central bull gear 6; Four small gears 5 are located in an external gear 7 and are all meshed with the external gear 7; the external gear 7 is fixed on the bracket 8; the central bull gear 6 is coaxially equipped with a driving gear 9, and the driving gear 9 passes through the transmission The gear 10 is connected with the drive motor 11; the drive motor 11 is fixed on the bracket 8.

[0016] During pipe jacking construction, four jacks are used to exert force on four points on the end surface of the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com