Connection device and method for large-section steel truss girders

A technology of docking device and steel truss girder, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large reaction force at the front fulcrum, large axial deformation, and inability to directly connect large-section steel truss girder, etc. Achieve the effect of improving utilization rate, simple structure and reducing engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

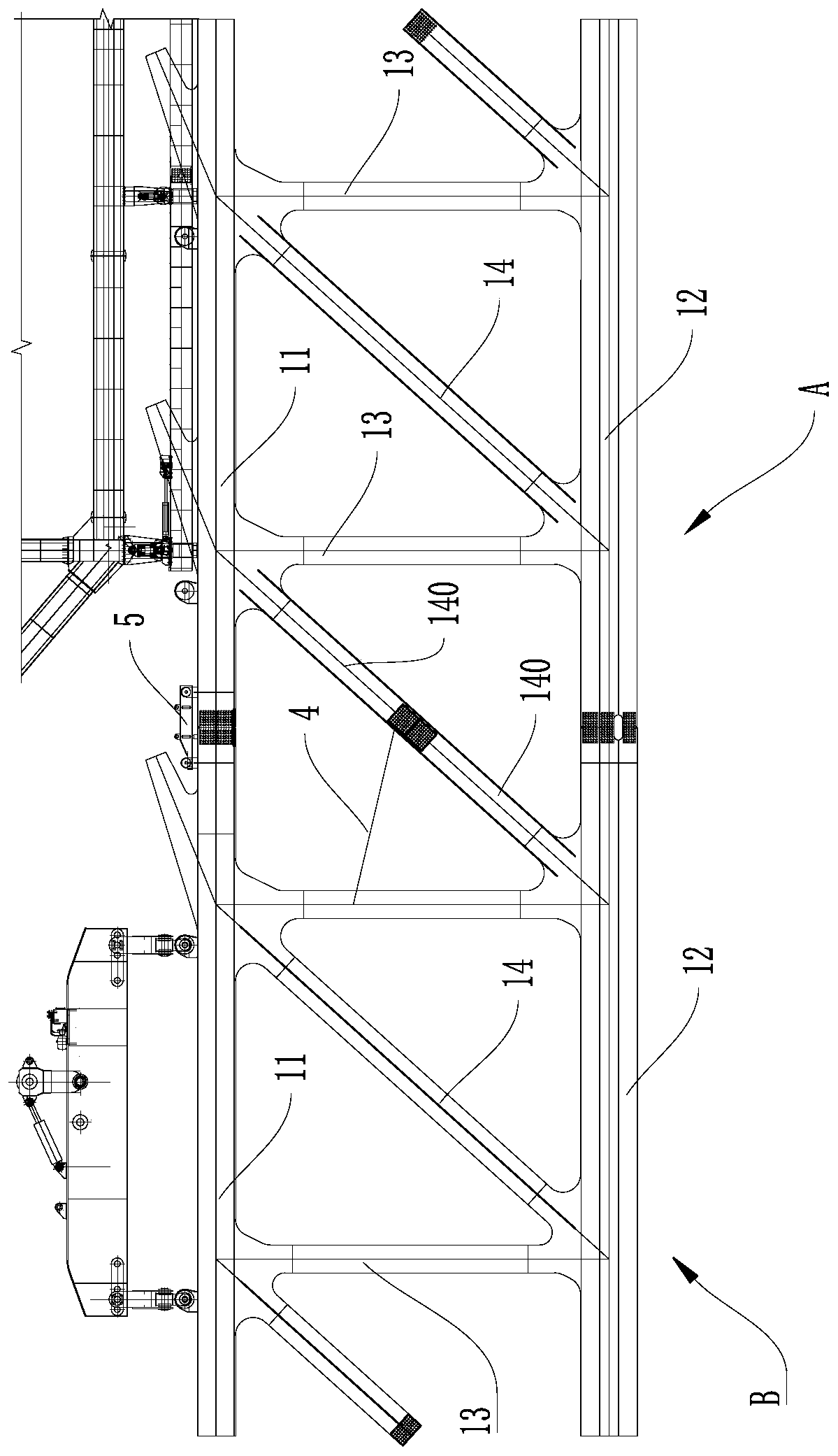

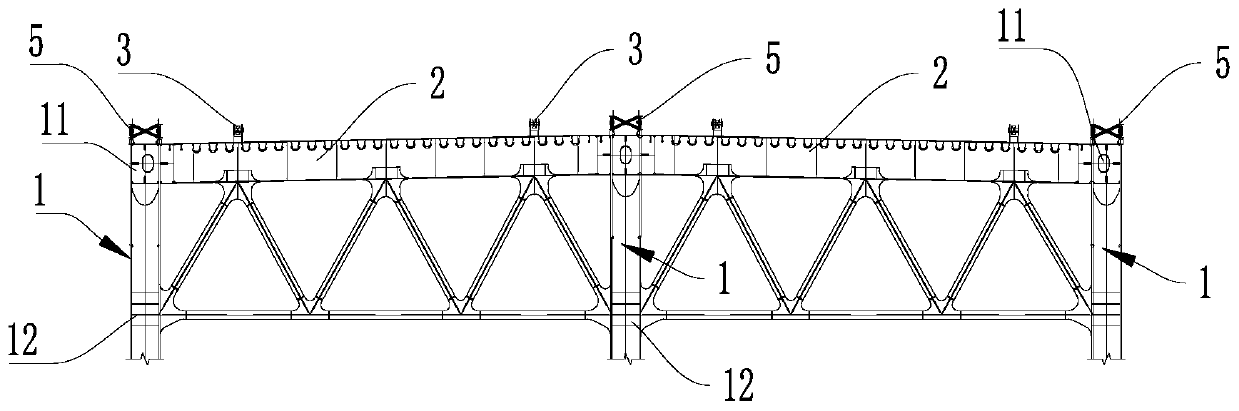

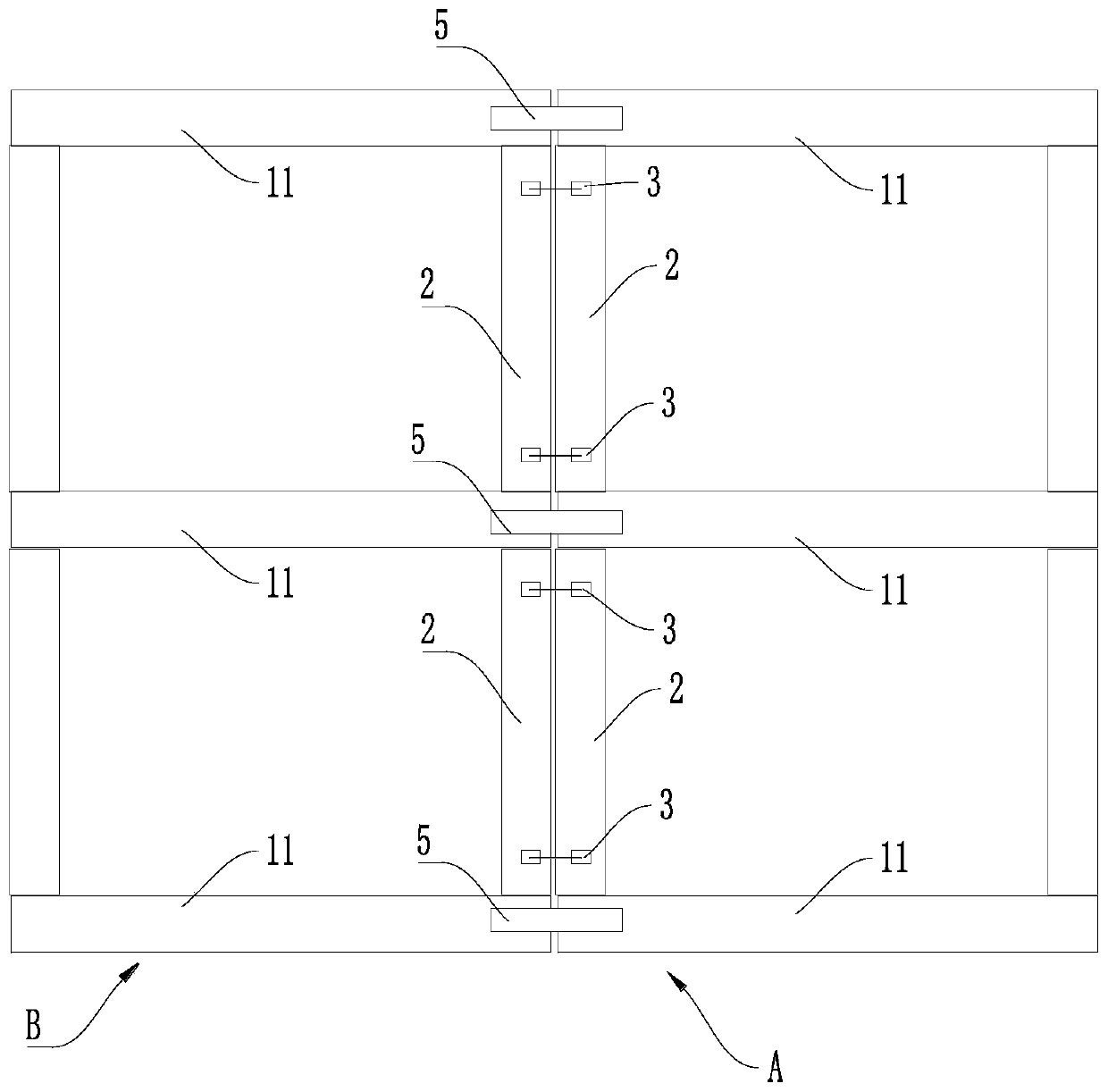

[0052] see Figure 1~3 As shown, the embodiment of the present invention provides a butt joint device for large-segment steel truss girders, which is used for butt jointing two large-segment steel truss girders, and defines two large-segment steel truss girders as erected beam segment A And the beam section B to be erected; the large section steel truss beam includes:

[0053] Several groups of string beam units 1 arranged at intervals in parallel, each string string unit 1 includes an upper string 11, a lower string 12, at least one vertical rod 13 connected to the upper string 11 and the lower string 12, and two The docking rod 140 outside the vertical rod 13;

[0054]A plurality of large crossbeams 2, at least two large crossbeams 2 are arranged between every two adjacent upper chords 11, and two described large crossbeams 2 are respectively arranged at two ends of the two described upper chords 11, to be erected The large beam 2 in the beam section B is set opposite to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com