Welding device and welding method for socket and spigot joint of winding pipe

A technology of welding device and socket joint, which is applied in the field of winding pipe processing, can solve the problems of high manpower consumption for heating plate, easy movement of large-diameter pipe parts, frequent disassembly and assembly of fixtures, etc., and achieves production efficiency and docking quality assurance. The product has a wide range of applications and the effect of avoiding hidden dangers in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

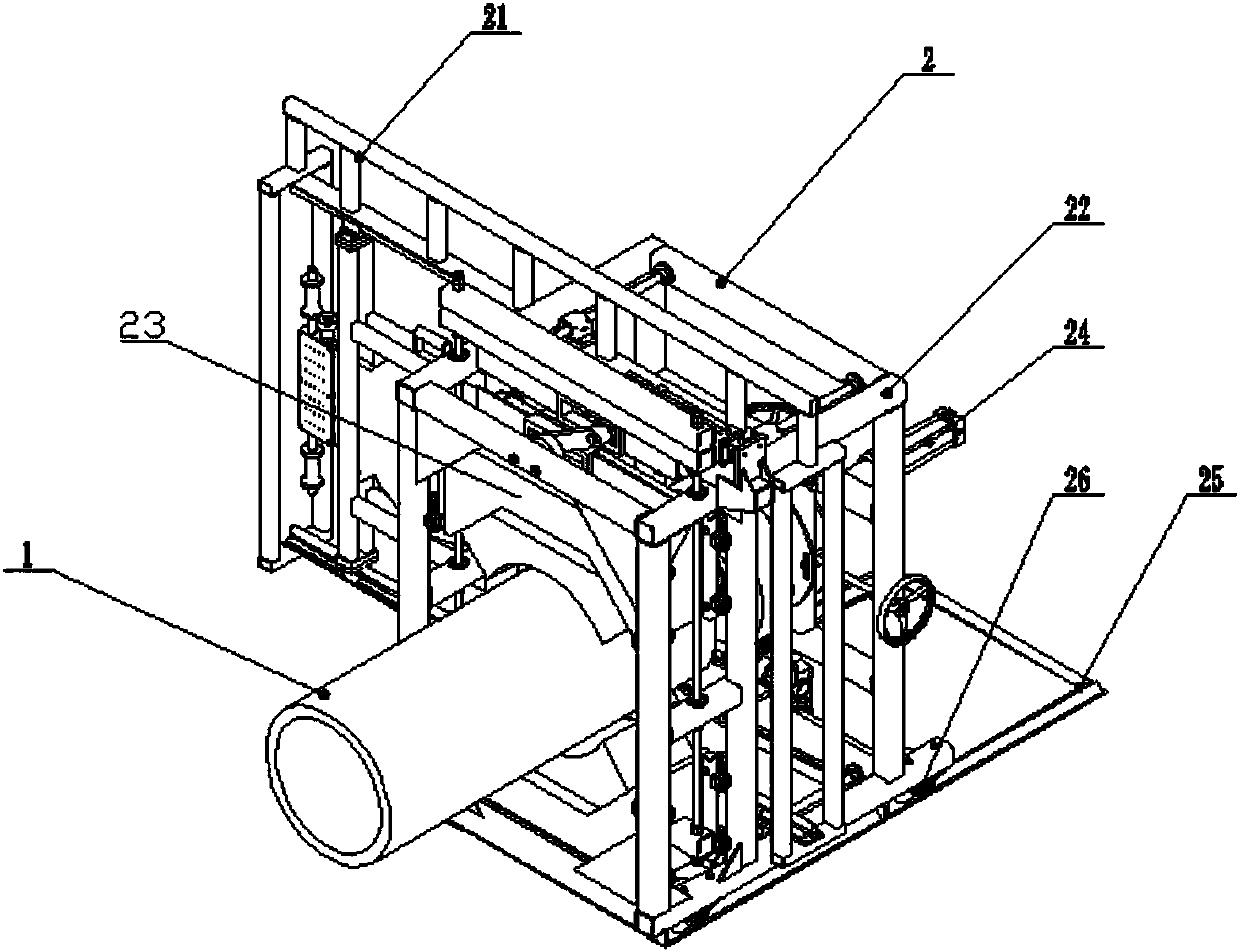

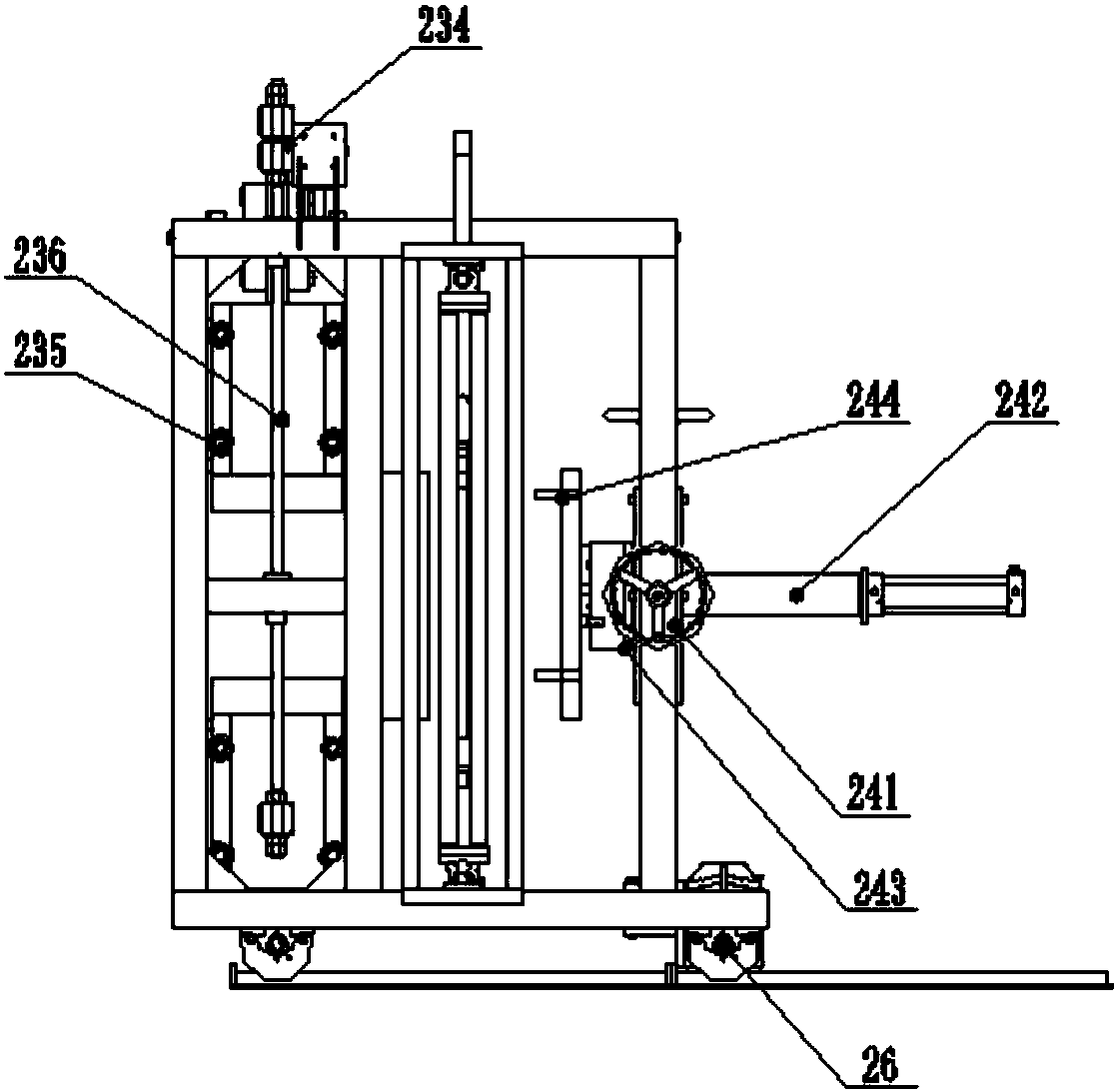

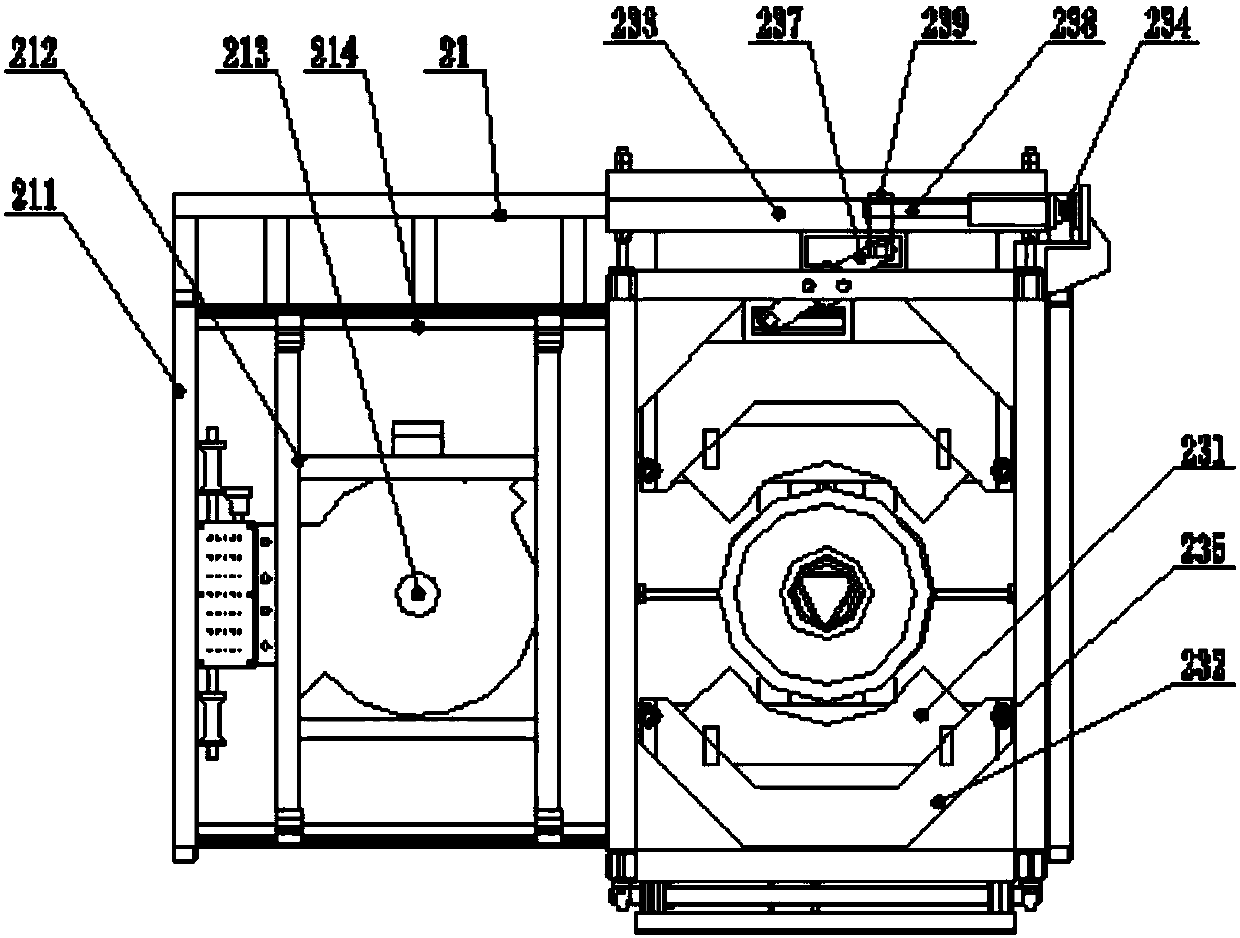

[0038] like figure 1 , figure 2 and image 3 As shown, a welding device for winding pipe socket joints includes a mobile base and a main body of the welding device arranged on the mobile base. The main body of the welding device includes a heating plate device 21, a main frame of the welding device 22, a pipe clamping device 23 and pipe fittings Installing device 24, heating plate device 21 is arranged on welding device main frame 22 middle parts, pipe clamping device 23 and pipe fitting installation device 24 are respectively installed on both sides of heating plate device 21; The pulley 26 and the main frame moving guide rail 25 slidably connected therewith, the main frame moving guide rail 25 are arranged in parallel on both sides of the base, and the main body of the welding device can move as a whole.

[0039] The pipe is placed on a pipe rack that is close to the welding device, and the main body of the welding machine moves in the direction of the pipe as a whole thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com