Method for butting straight bent pipe and straight pipe of long transmission line pipeline with small and medium pipe diameters in air

A technology of aerial docking and straight bending, which is applied to tubular objects, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the labor intensity of construction personnel, consuming manpower, material resources, and having potential safety hazards, shortening the construction period, reducing The effect of labor intensity and improving docking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

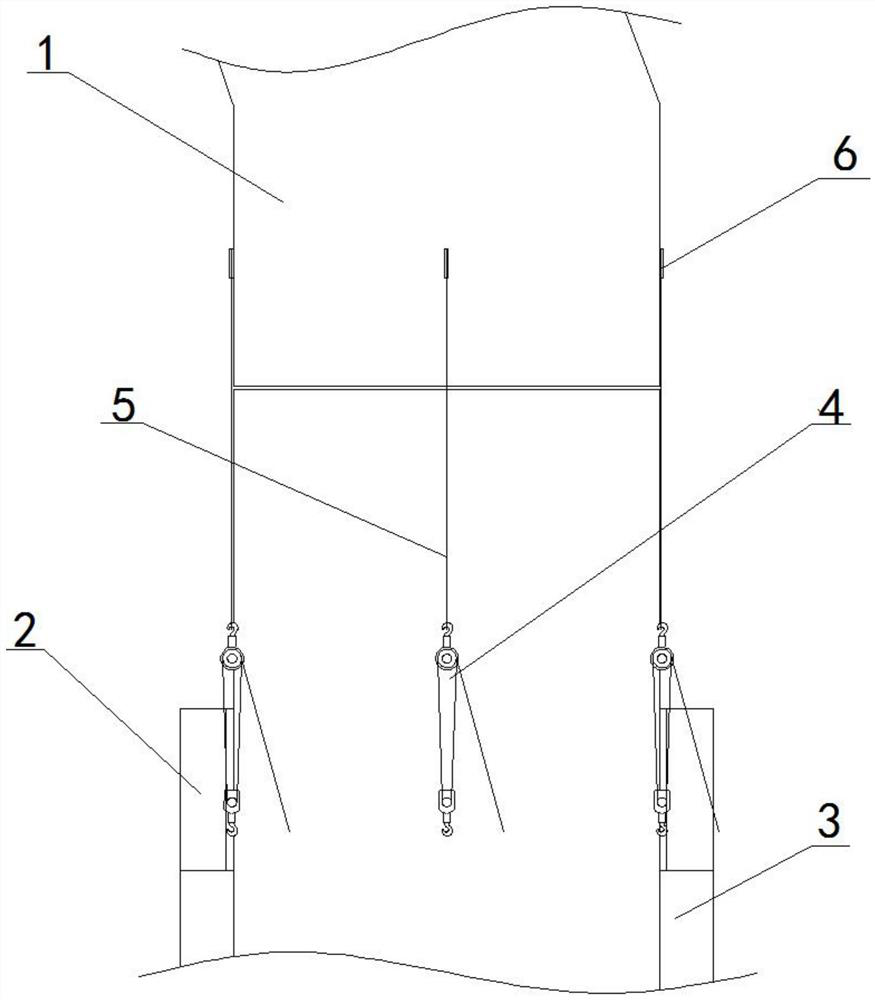

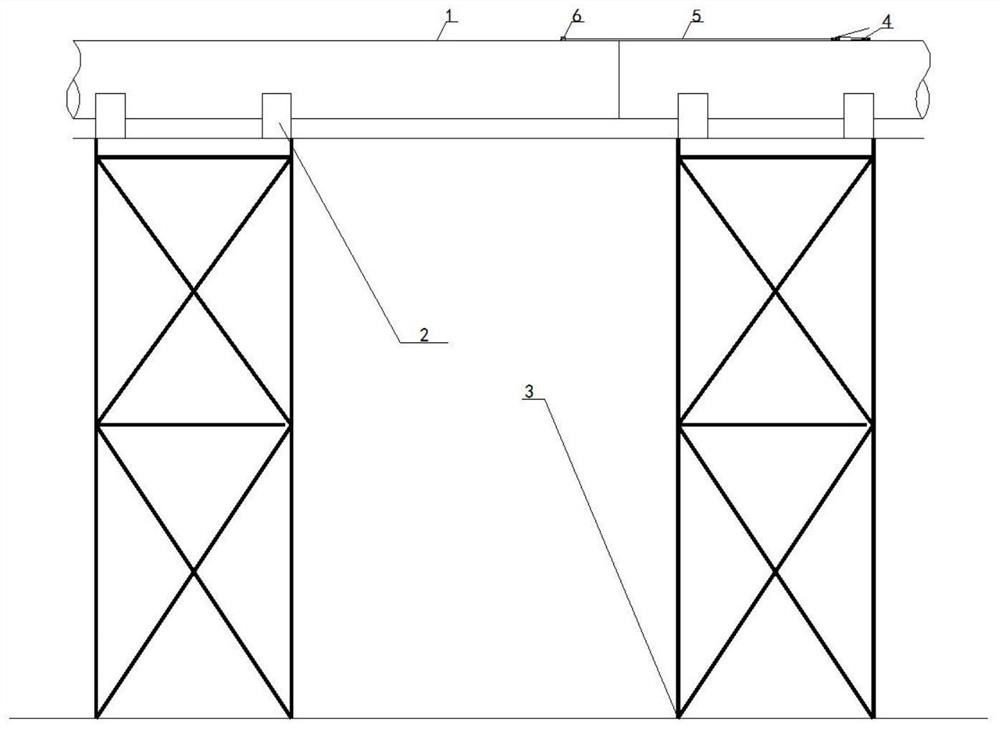

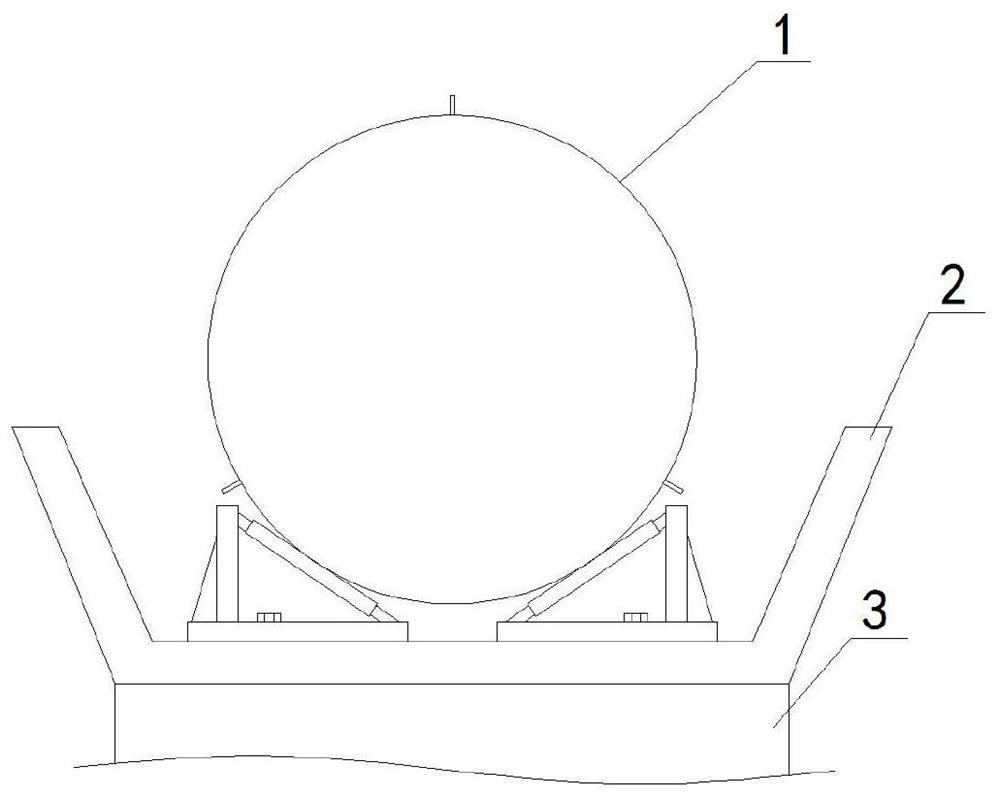

[0026] like Figure 1-4 As shown, the method for connecting the straight bend pipe and the straight pipe of the small and medium diameter long transmission line pipeline in the air includes the following specific steps:

[0027] S1 ground assembly straight bend pipe section 1: select a flat site at the construction site, assemble the straight pipe part and the bend pipe part, and complete the welding to obtain the straight bend pipe section 1;

[0028] S2 Weld traction positioning block: Weld traction positioning block 6 on the curved pipe part of straight pipe section 1. The welding position is located at the outer periphery of one end of the curved pipe part close to the straight pipe part. The traction positioning block 6 is provided on the side away from the straight pipe part open mouth

[0029] S3 Set the bracket 3: Fix at least two brackets 3 on the construction site. The upper end of the bracket 3 is equipped with a pipe support 2 to prevent the pipe fittings from rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com