Treatment method of deviation and fracture remediation of pile body of filling pile

A treatment method and cast-in-situ pile technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of unfavorable overall benefits and organizational management, the inability to modify the design, and the large amount of design modification, etc., to achieve low overall cost, The effect of high construction requirements and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

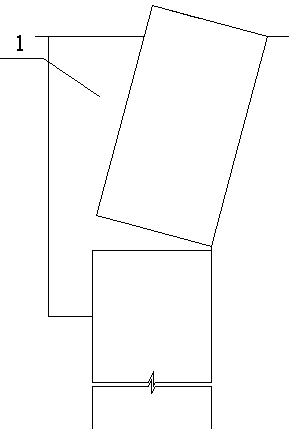

[0069] Such as Figure 1 to Figure 6 Shown: the upper part of the cast-in-situ pile of the present embodiment is deflected, and a fracture is arranged, and the specific method steps of its remedial treatment are as follows:

[0070] 1) Low strain measurement to determine the defect position of the pile; determine where the pile deflects and breaks at the same time;

[0071] 2) Implementation of pile body correction:

[0072] a) Soil unloading: Unload soil 1 on the side to be reset, and unload the soil to 1m below the fracture depth ( figure 1 );

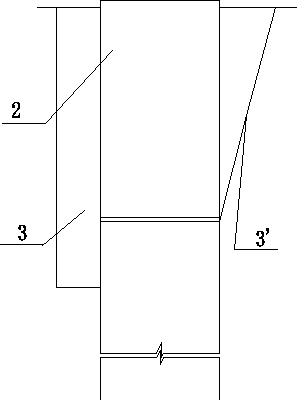

[0073] b) Pile body reset: Then reset the fractured and deflected pile body 2, pull it back to the design pile position or the approximate design pile position ( figure 2 );

[0074] c) Filling: After the deviation correction is completed, fill the sand and gravel mixed filler 4 in the unloading area 3 and the void area 3' generated after the deflected pile body is pulled back ( figure 2 , 3 );

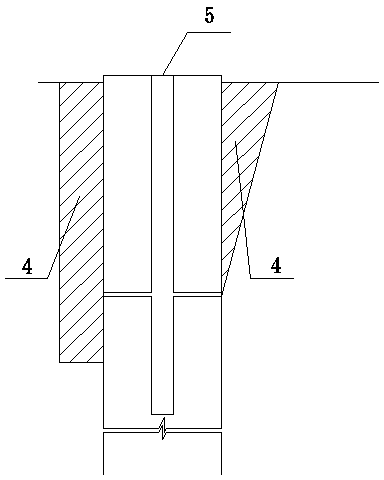

[0075] 3) Pile top drilling ...

Embodiment 2

[0090] The remedial treatment steps of embodiment 2 and embodiment 1 are basically the same.

[0091] The diameter of the defective pile in Example 2 is 1 m. After steps 1 and 2, step 3) when drilling and coring the top of the pile, drill two 11cm holes on the top of the pile;

[0092] After steps 4 and 5, step 6) When high-pressure cement slurry punching and grouting, configure cement slurry with a water-cement ratio of 0.7, use high pressure to wash the defect position back and forth several times, and control the pressure at 16Mpa to carry out punching and grouting, filling Small gaps at defect locations;

[0093] Step 7) When intubating, also insert the grouting pipe 7, the special pipe for quick-setting agent 7' and the unloading pipe 8. The length of the special pipe 7' for the agent reaches 10cm below the defect position, the grout discharge pipe 8 extends into the core hole 5 by 100cm, and both the grout injection pipe 7 and the grout discharge pipe 8 are 30cm higher...

Embodiment 3

[0101] Such as Figure 9 to Figure 13 As shown: the pile foundation defect in this embodiment is not only one deflection fracture, but also has two deflection fracture parts. The broken part, so the specific operation has its special place:

[0102] 1) Low strain measurement to determine the defect position of the pile; determine where the deflection and fracture of the pile occur;

[0103] 2) Implementation of pile body correction:

[0104] a) Soil unloading: Unload soil 1 on the side to be reset, and unload the soil to 1m below the fracture depth ( Figure 8 );

[0105] b) Pile body reset: Then reset the upper broken and deflected pile body 2, ( Figure 9 );

[0106] When implementing the two steps a) and b) above, the deflection and fracture of the upper section of the pile body shall be corrected first, and then the deflection and fracture of the pile body of the lower section shall be corrected ( Figure 10 ), and reset the pile body to the design pile position or app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com