Support-free long-distance compensation method and system for ground-burying type pipe

A compensation method and buried technology, applied in the field of compensation method and corresponding pipeline system, can solve the problems of short safety life and large investment, and achieve the effects of simplified installation process, simple installation process and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

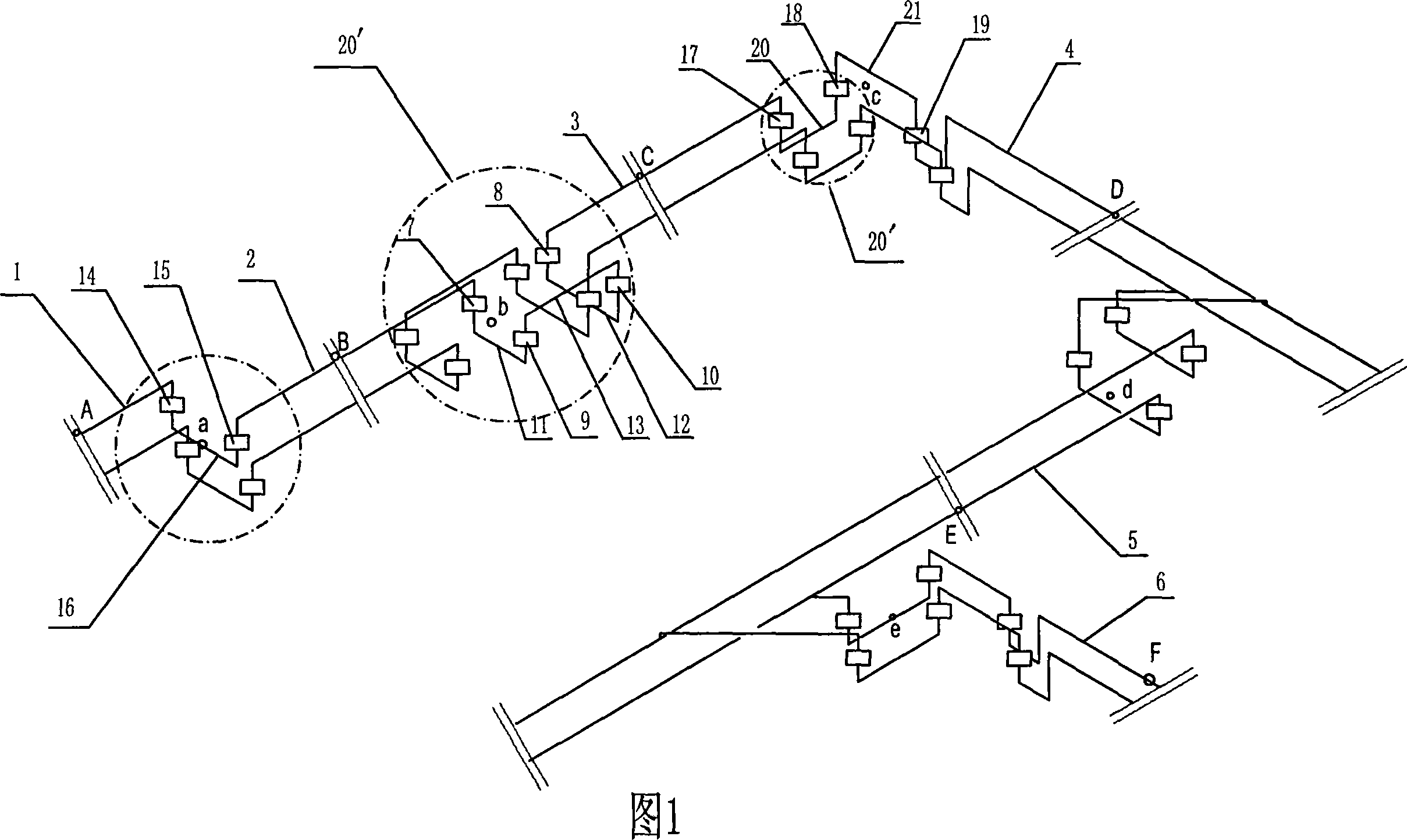

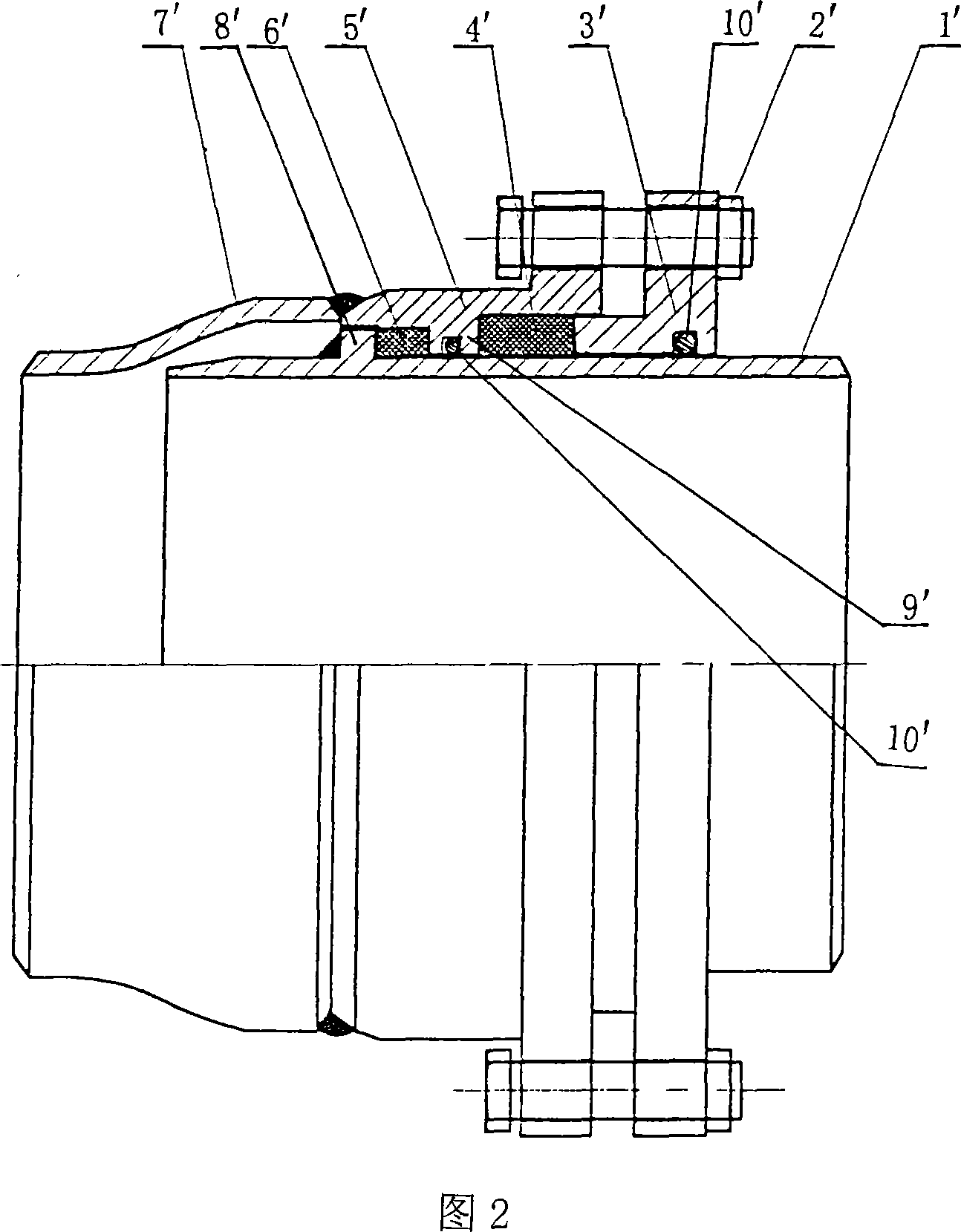

[0028] The following structural drawings and embodiments further illustrate the present invention.

[0029] As shown in Figure 1 and 2.

[0030] The unsupported and long-distance compensation method for buried pipelines of the present invention is to firstly place the pipelines to be auxiliary directly on the untreated soft ground below the ground; secondly, at the set compensation position (two adjacent The distance between the compensation positions can be up to 500 meters) or at the turn to install two or more rotary compensators to compensate for the change in the length of the pipeline due to thermal expansion and contraction. The rotary compensators are installed in In the hollow buried concrete structure or steel structure installation foundation, the hollow buried concrete structure or steel structure installation foundation is either a hollow structure without any filler added, or filled with compressible materials or soft soil The solid structure of the buried concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com