Flattening tool for end part of corrugated pipe

A corrugated pipe and tool technology, which is applied to the device field of incision processing after metal corrugated pipe cutting, can solve problems such as unevenness of the corrugated pipe port, and achieve the effects of good flatness, improved docking quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

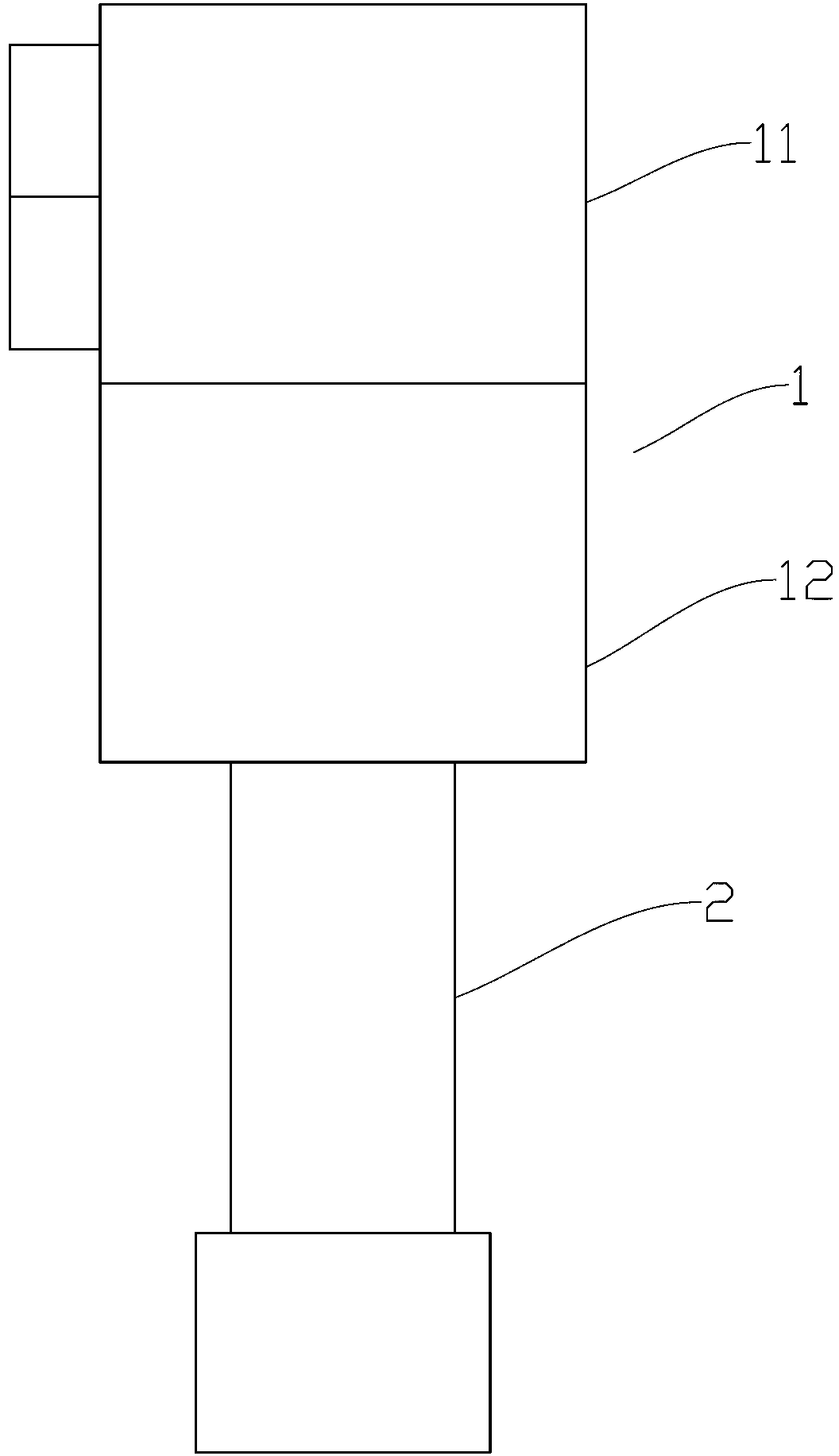

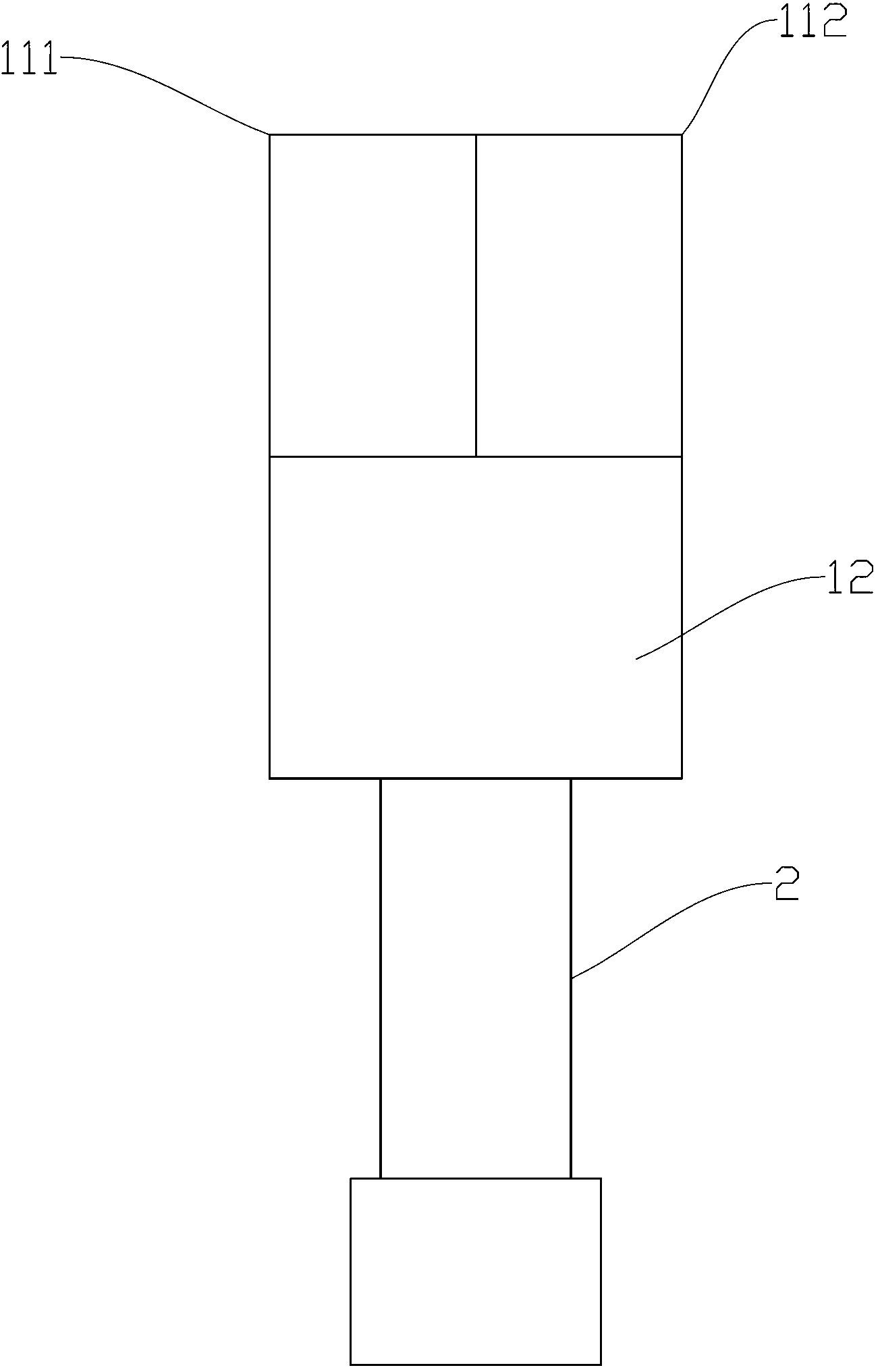

[0018] Such as figure 1 , 2 , 3 and 4, the bellows end flattening tool includes a first component 1 and a second component 2 .

[0019] The first component 1 is cylindrical and consists of an upper section 11 and a lower section 12 divided axially.

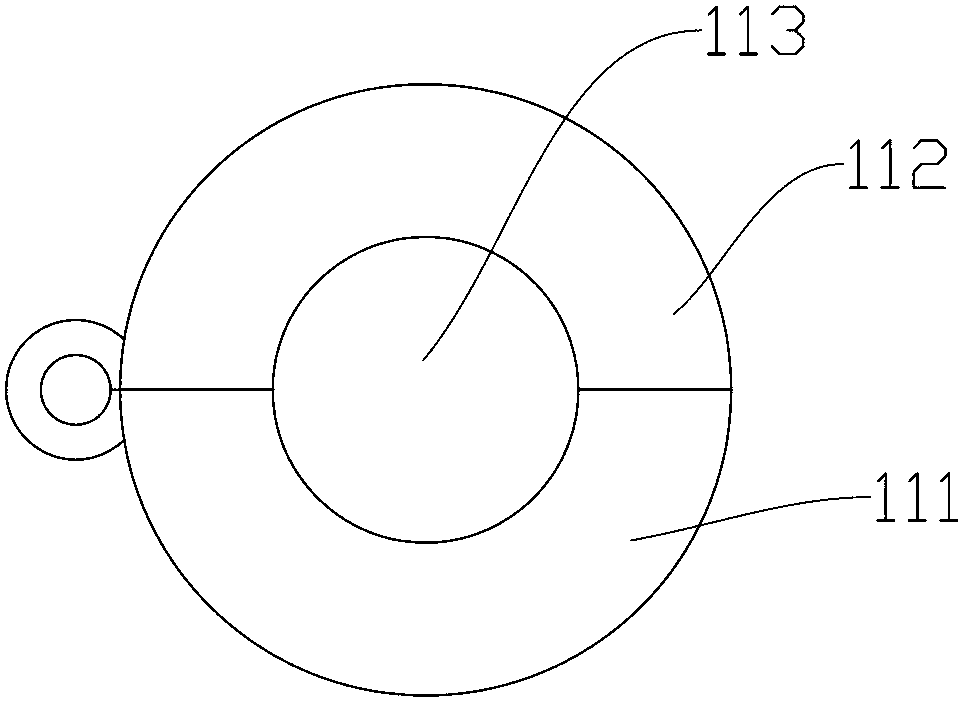

[0020] The upper section 11 is hinged by a first half cylinder 111 and a second half cylinder 112 , and the hinge axis 13 is parallel to the axial direction of the first component 1 . The upper section 11 is provided with a stepped hole made of a small round through hole 113 and a large round through hole 114, the small round through hole 113 is located above the large round through hole 114; the small round through hole 113 is respectively arranged on the first half cylinder 111, The small semicircular grooves on the second half cylinder 112 are fastened together, and the large circular through hole 114 is formed by fastening the large semicircular grooves on the first semicircular cylinder 111 and the second semicircular cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com