Ridging and ditching integrated machine

An all-in-one machine and ridge-building technology, which is applied in the field of farm tools, can solve problems such as the inability to ensure land leveling, the ineffective drainage of rainwater, and the impact on crop growth, etc., and achieve the goal of reducing the number of repeated operations, reducing the possibility, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

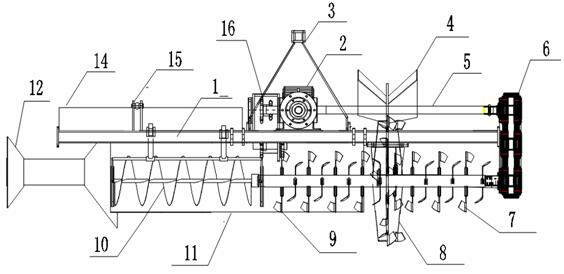

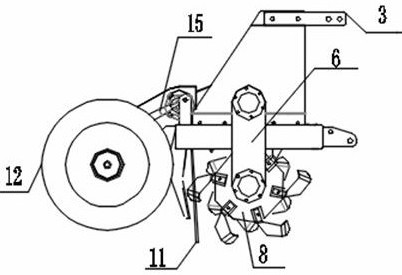

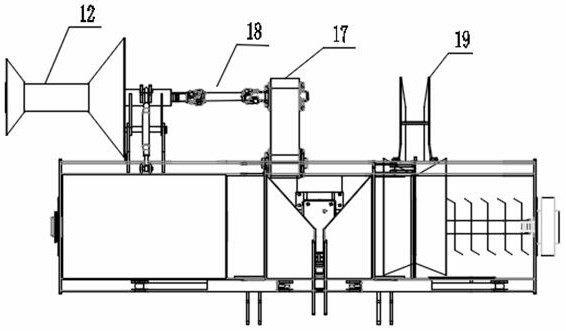

[0031] In the present invention, the power output end of the traction device is connected to the intermediate gear box 2, the output shaft of the intermediate gear box 2 is connected to the transmission shaft 5, and the transmission shaft 5 is connected to the power input end of the side gear box 6, and the power of the side gear box 6 The output end is connected to the rotating shaft, and the rotary tiller 7, the ditching cutter head 8, the leveling knife 9, and the screw conveyor 10 on the rotating shaft rotate simultaneously. During specific operations, the rotary tiller rotates the soil to loosen the soil and open The ditch cutter head 8 rotates with the ditching blade to realize ditching. After ditching, it is leveled by the leveling knife 9 to make the land level. The excess soil is transported to the front of the ridge builder 12 through the screw conveyor 10. When the traction device moves forward When moving, the intermediate gear box 2 drives the universal joint 18 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com