Method of controlling arc length of additive manufacturing arc and flatness of end face of formed part

A technology for additive manufacturing and formed parts, which is applied in the field of controlling the arc length of additive manufacturing and the flatness of the end face of the formed part, which can solve the problems of the decline in the flatness of the end face of the formed part, and achieve the effect of improving the flatness and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

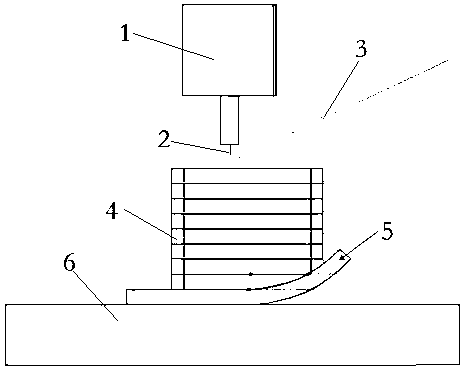

[0030] Build a TIG arc additive manufacturing platform, which includes welding machines, wire feeders and machine tools;

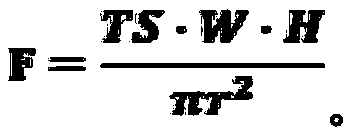

[0031] Establish the relationship function between the theoretical wire feeding speed F and the additive manufacturing speed TS;

[0032] Keep the standard arc length unchanged during welding, perform single-pass single-layer welding on the TIG arc additive manufacturing platform, record the welding current and voltage in real time through the display system of the welding machine, and fit the recorded welding current and voltage to obtain the welding current and the linear regression equation of the voltage, defining the voltage in the linear regression equation under the standard arc length as the standard voltage;

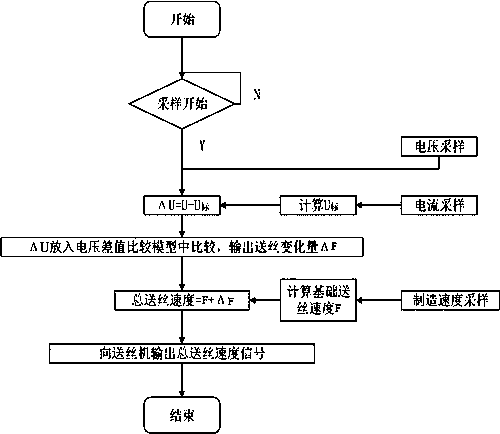

[0033] Input the linear regression equation of welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com