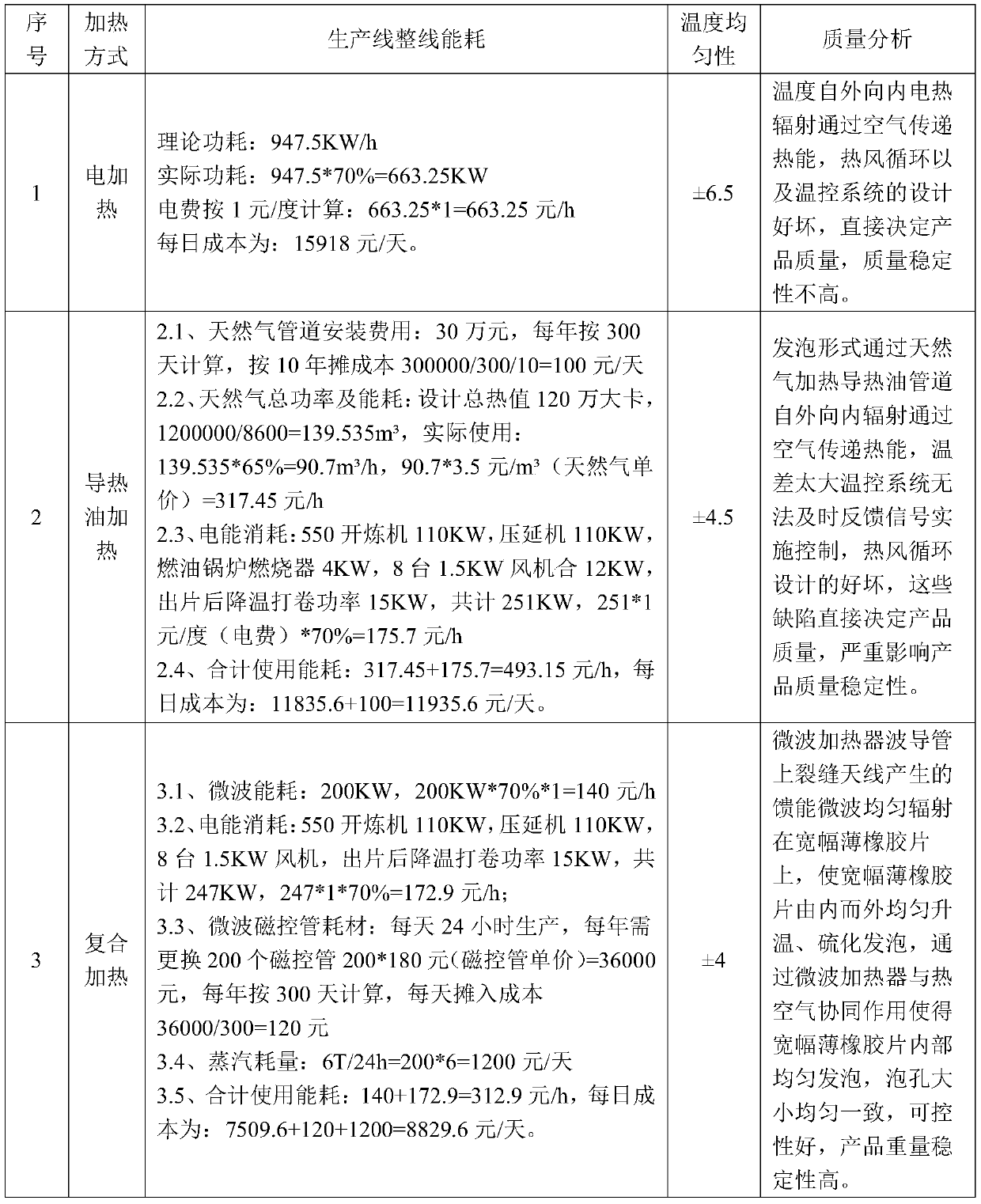

Wide-width thin rubber sheet foaming technology based on infrared ray, steam and microwave composite heating

A technology of composite heating and microwave heater, applied in the field of rubber foaming, can solve the problems of high energy consumption, unenvironmental protection, low qualified rate of finished products, etc., and achieve the effects of good temperature uniformity, energy saving, and uniform cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

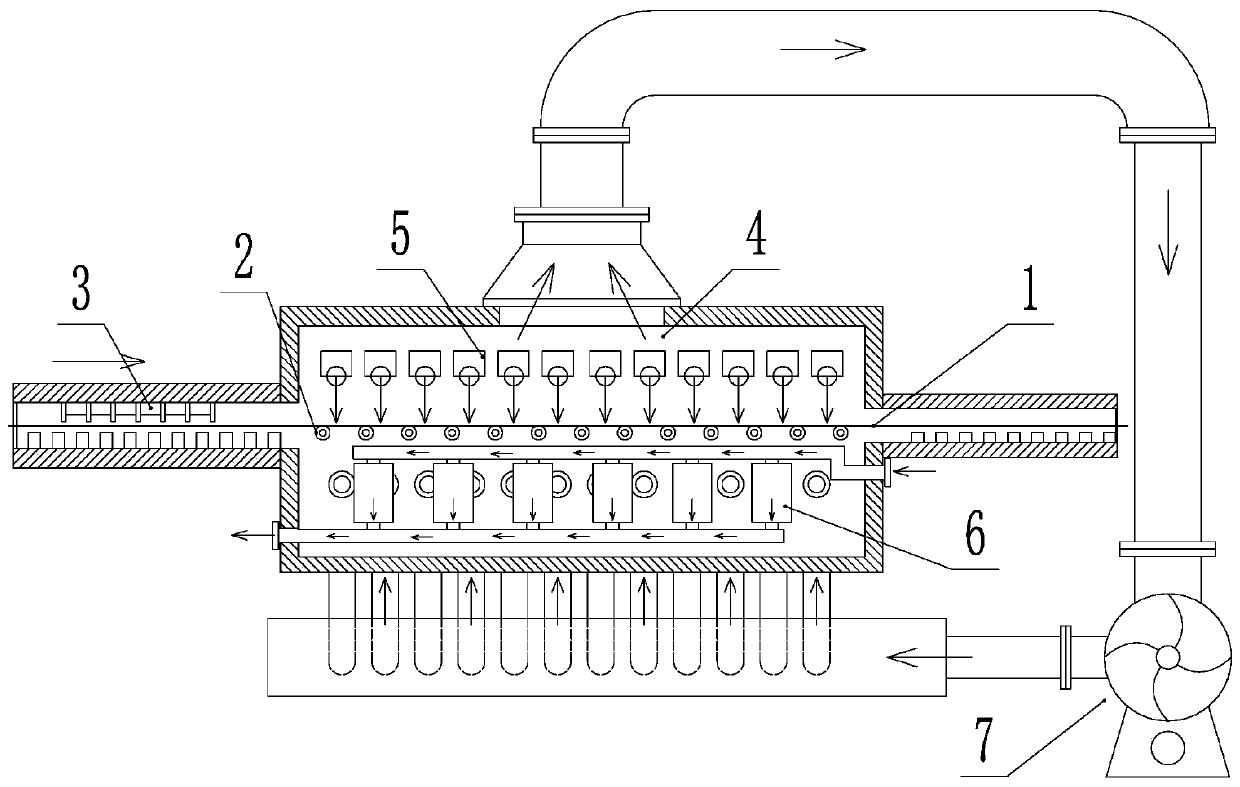

Method used

Image

Examples

Embodiment 1

[0029] Follow the steps below:

[0030] Step A, mixing the rubber, foaming agent, and vulcanizing agent evenly, and extruding them through a calender to obtain an unvulcanized and foamed wide-width thin rubber sheet;

[0031] Step B. Use a steam coil radiator to heat the air in the foaming furnace at a heating temperature of 130°C. The steam boiler provides the steam source for the steam coil radiator. At the same time, a hot air circulation system is used, that is, through the high temperature resistant fan and the foaming furnace The pipeline is connected to form a loop to circulate the air in the foaming furnace. After heating for a period of time, the temperature in the foaming furnace is evenly distributed and basically stable;

[0032] The length obtained in step C and step A is 500mm, the width is 300mm, the thickness is 1.3mm, and the density is 1.1-1.4g / cm 3 , the wide-width thin rubber sheet with a moisture content of <2% is fed into the foaming furnace through the ...

Embodiment 2

[0036] Follow the steps below:

[0037] Step A, mixing the rubber, foaming agent, and vulcanizing agent evenly, and extruding them through a calender to obtain an unvulcanized and foamed wide-width thin rubber sheet;

[0038] Step B. Use the steam coil radiator to heat the air in the foaming furnace at a heating temperature of 146°C. The steam boiler provides the steam source for the steam coil radiator. At the same time, a hot air circulation system is used, that is, through the high temperature resistant fan and the foaming furnace The pipeline is connected to form a loop to circulate the air in the foaming furnace. After heating for a period of time, the temperature in the foaming furnace is evenly distributed and basically stable;

[0039] The length obtained in step C and step A is 500mm, the width is 300mm, the thickness is 1.5mm, and the density is 1.1-1.4g / cm 3 , the wide-width thin rubber sheet with a moisture content of <2% is sent into the foaming furnace through t...

Embodiment 3

[0043] Follow the steps below:

[0044] Step A, mixing the rubber, foaming agent, and vulcanizing agent evenly, and extruding them through a calender to obtain an unvulcanized and foamed wide-width thin rubber sheet;

[0045] Step B. Use the steam coil radiator to heat the air in the foaming furnace at a heating temperature of 150°C. The steam boiler provides the steam source for the steam coil radiator. At the same time, a hot air circulation system is used, that is, through the high temperature resistant fan and the foaming furnace The pipeline is connected to form a loop to circulate the air in the foaming furnace. After heating for a period of time, the temperature in the foaming furnace is evenly distributed and basically stable;

[0046] The length obtained in step C and step A is 500mm, the width is 300mm, the thickness is 1.8mm, and the density is 1.1-1.4g / cm 3, the wide-width thin rubber sheet with a moisture content of <2% is sent into the foaming furnace through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com