Large thin-wall cylindrical component automatic abut-joint assembling flexible positioning device

A flexible positioning and automatic docking technology, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve problems such as low docking accuracy, poor compliance, and damage to thin-walled parts, and achieve high compliance performance and improved compliance Sexuality, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

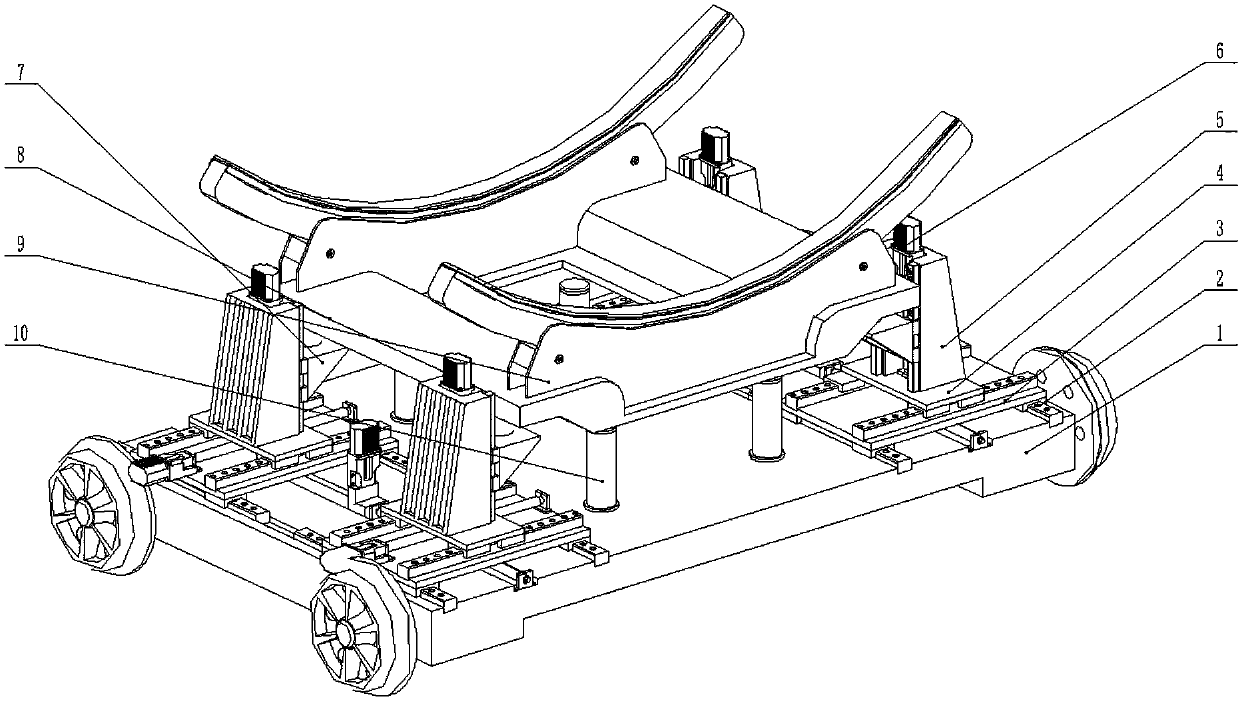

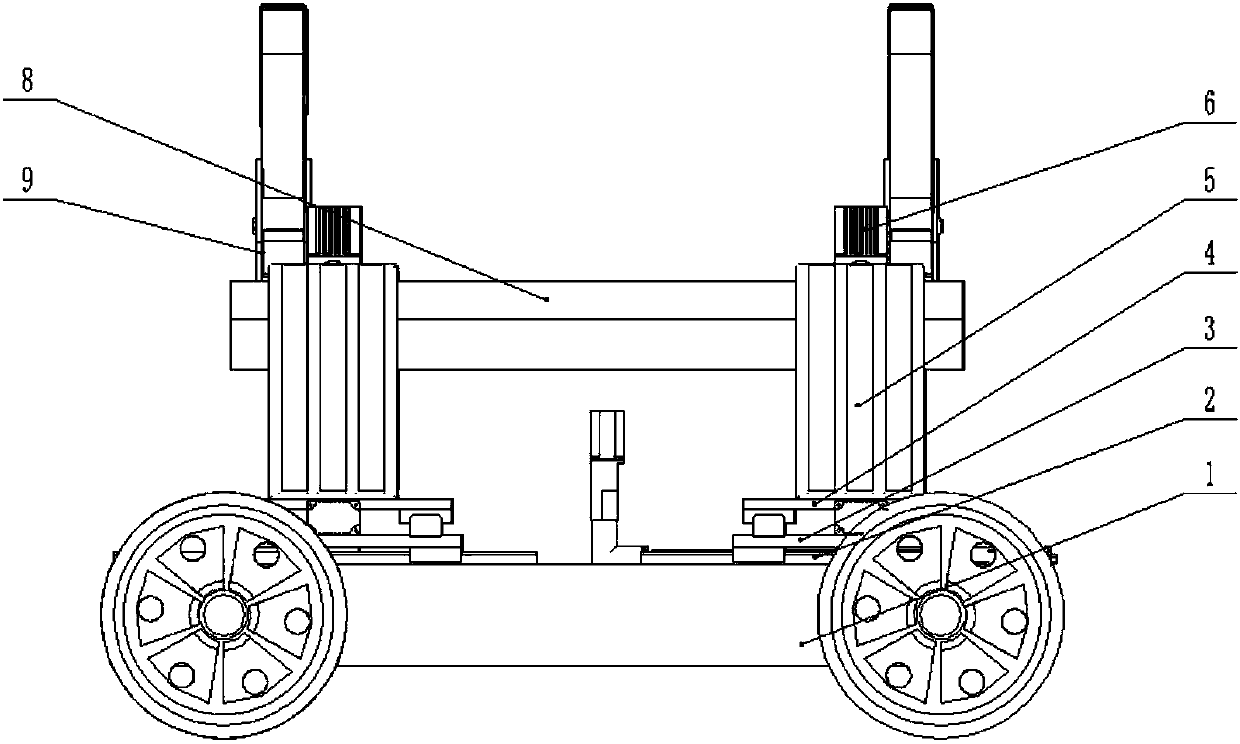

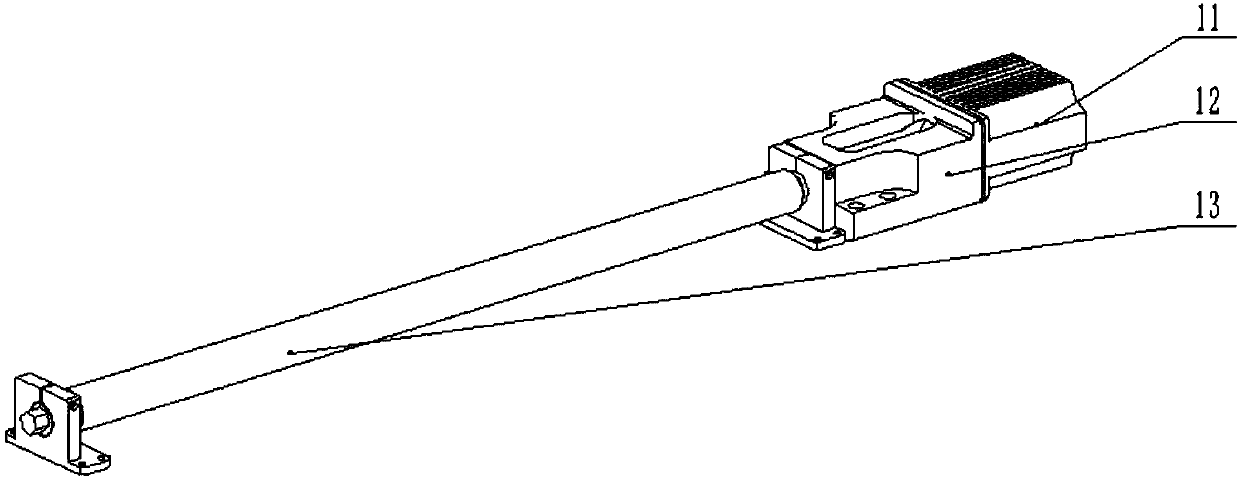

[0026] Such as figure 1 with figure 2 As shown, in this embodiment, the mobile bottom car 1, the guide rail slider 2, the axial mobile platform 3, the lateral mobile platform 4, the vertical support tower 5, the power unit 6, the supporting ball joint seat 7, the moving platform 8, and the flexible bracket 9 and a load-bearing safety pillar 10, wherein: the mobile bottom vehicle 1, the axial mobile platform 3, and the lateral mobile platform 4 are sequentially connected by a power device 6, the vertical support tower 5 is rigidly connected with the lateral mobile platform 4, and the vertical support tower 5 is connected with the supporting ball joint seat 7 through the power device 6, and the supporting ball joint seat 7 is connected with the moving platform 8 in the form of a ball and socket, and the flexible bracket 9 is placed on the top of the moving platform 8 and rigidly connected, so that the bearing is safe The pillar 10 is rigidly connected with the mobile base vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com