Gas-taking joint and online gas-taking method

A technology of gas joints and plug joints, which is applied in the field of gas intake joints, can solve problems such as gas leakage, and achieve the effect of eliminating gas leakage and clearing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings to help readers better understand the solutions of the present invention and the beneficial effects produced, but they cannot understand any limitations on the implementation and scope of the present invention.

[0034] The gas taking joint provided in this embodiment can be used especially in SF 6 Connect the air intake interface of the equipment and the air intake pipe of the detection system during the live detection of electric equipment, and implement standardized operations to complete the air intake process.

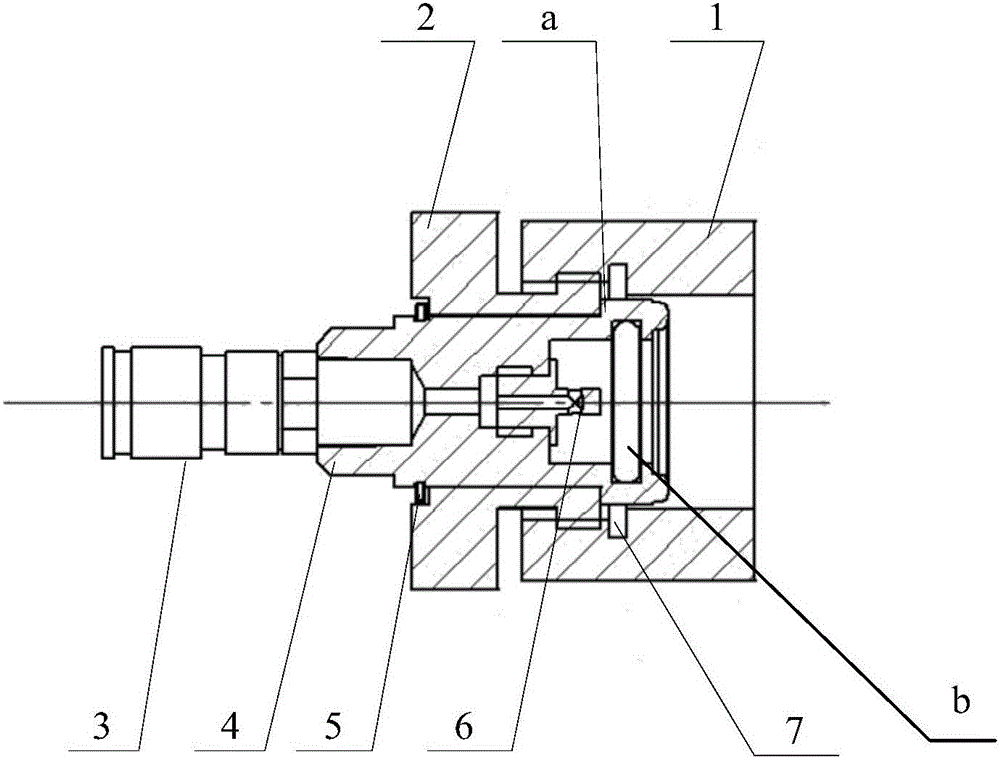

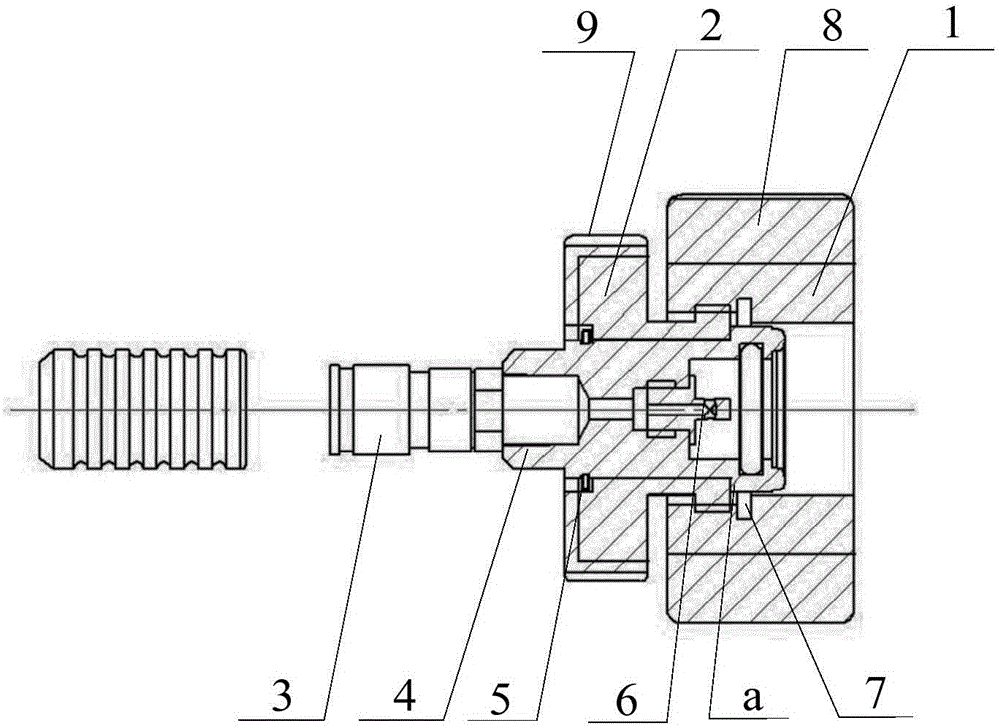

[0035] figure 1 It is a schematic cross-sectional structure diagram of an embodiment of the gas-taking joint of the present invention, including: a fixed nut 1, the internal thread at the front end of the fixing nut 1 can be screwed with the gas-taking interface of the equipment to be tested; the valve core 4 and the gas-taking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com