Dual-seal filling rotary compensator

A rotary compensator and injection filling technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem of rotary compensator leakage, which cannot be eliminated in time, and cannot be repaired online and other problems to achieve the effect of improving the sealing effect, eliminating hidden dangers of leakage, and simple double-seal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

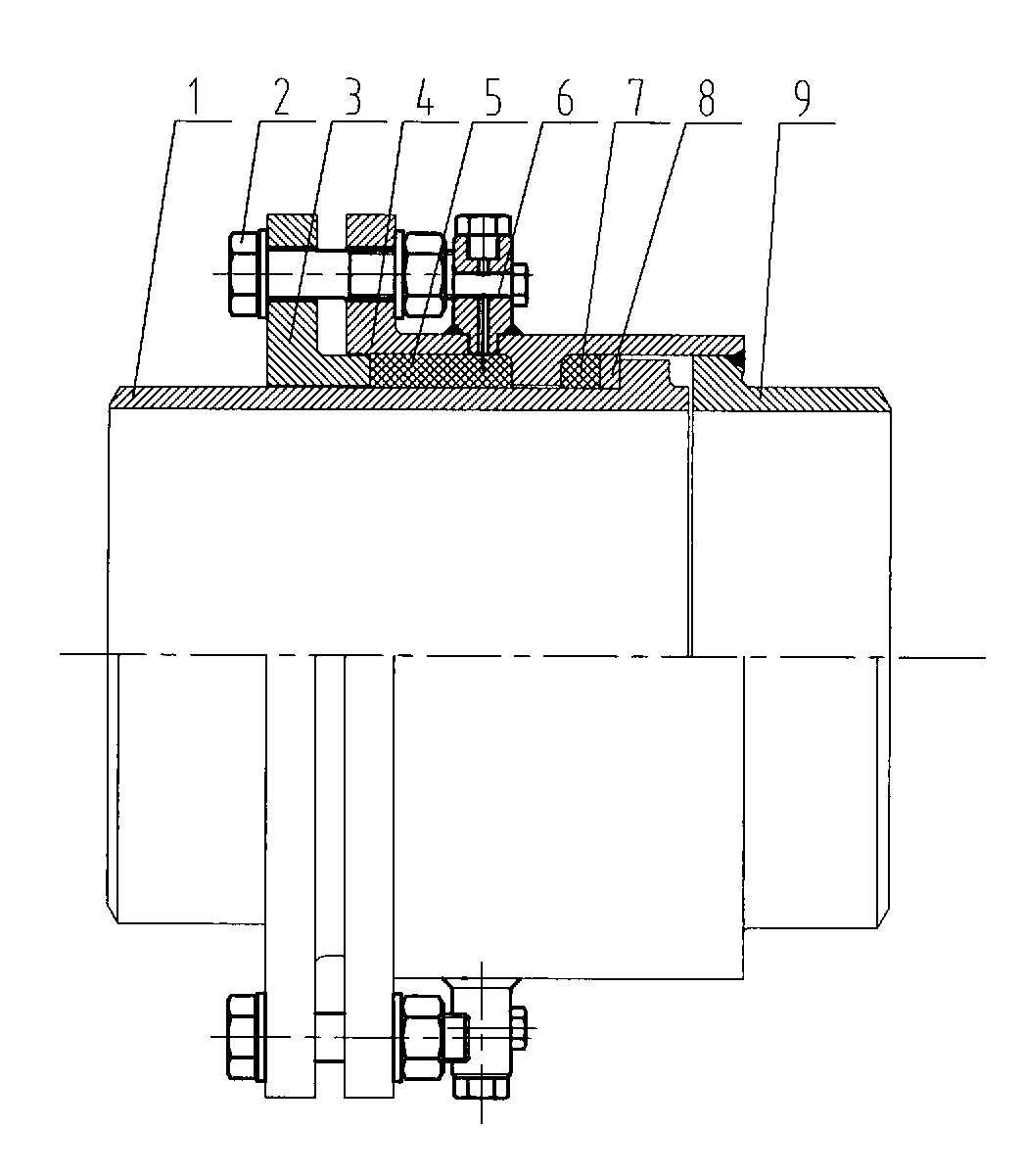

[0013] figure 1 The double-seal filling type rotary compensator shown includes inner pipe 1, fastener 2, gland 3, outer pipe 4, left packing 5, filling valve 6, right packing 7, sealing ring 8 and connecting pipe 9 . The outer wall of the right end of the inner tube 1 is provided with an annular step, and the outer tube is also provided with an annular step. The inner tube 1 is inserted into the sleeve from the right end of the outer tube 4, and the step on the outer wall of the inner tube 1 is located on the right side of the step on the inner wall of the outer tube 4, and a sealing ring 8 and a right packing 7 are set between the two steps to form a secondary sealing structure. The auxiliary sealing structure only plays a sealing role when the inner tube 1 produces axial displacement to the left, and is in a loose state at other tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com