Water delivery tank and its welding method

A welding method and water tank technology, which are applied in solar thermal power generation, heating devices, solar thermal devices, etc., can solve the problems of leakage at the weld, limited heat exchange area, low heat exchange efficiency, etc., and can eliminate the leakage at the weld. Hidden danger, high welding reliability, and the effect of eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

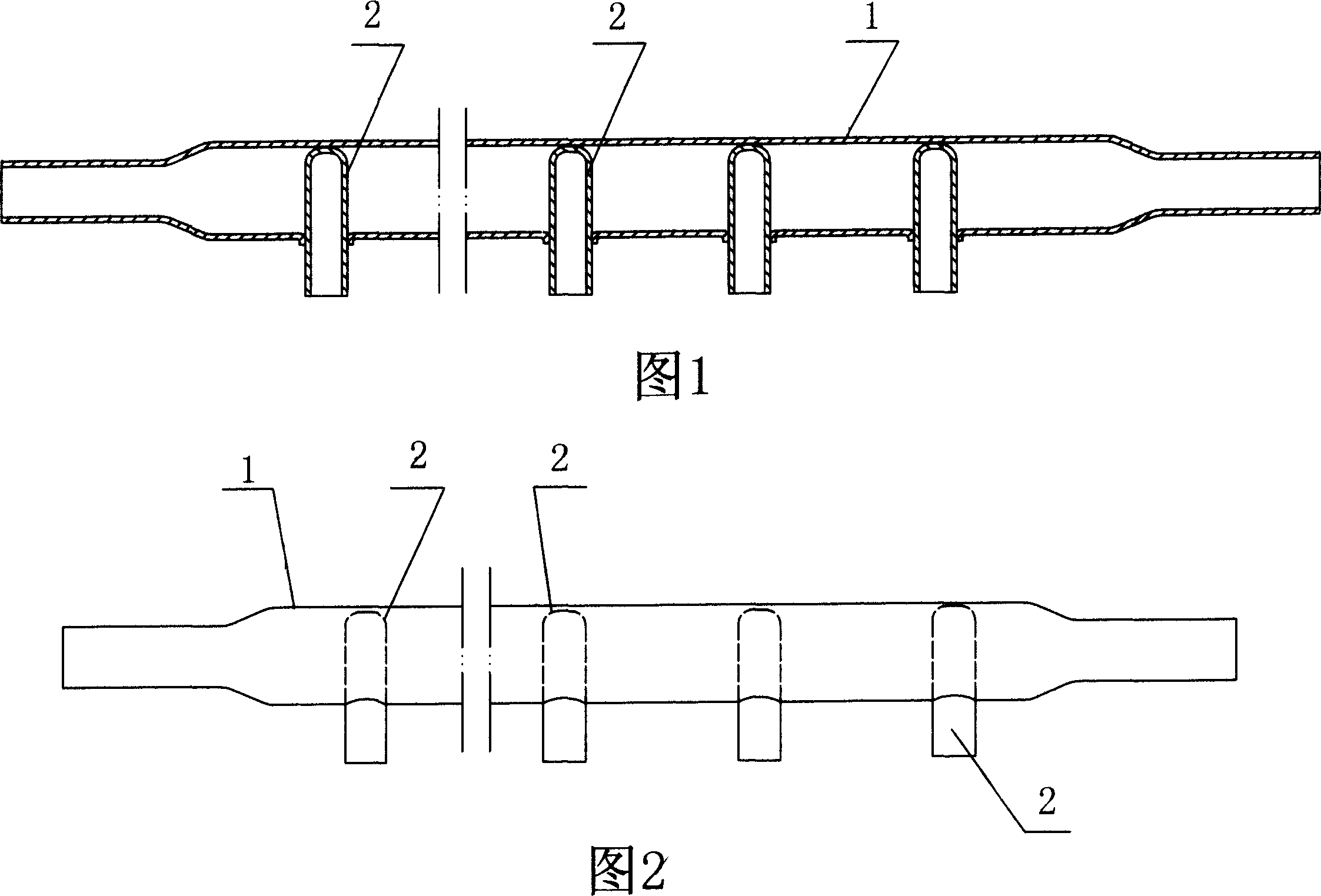

[0018] As shown in Figures 1 and 2, in the original flume, only one end of the sleeve 2 is inserted into the water main 1, and the sleeve 2 does not pass through the water main 1.

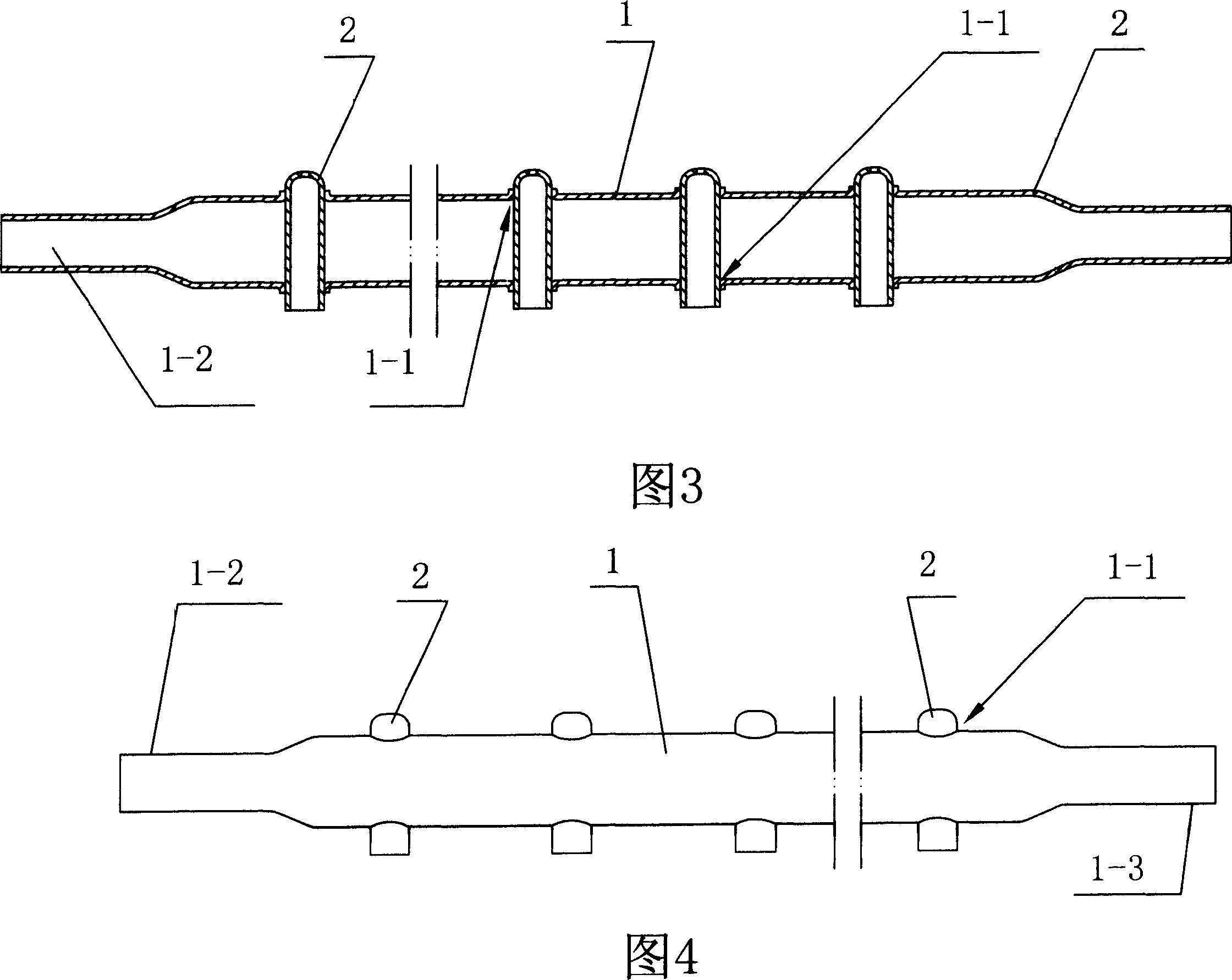

[0019] As shown in Figures 3 and 4, the water running trough of the present invention includes a water running main pipe 1 and a casing 2. The water running main pipe 1 has several transverse through holes 1-1, and the through holes 1-1 are fixedly equipped with a sleeve pipe 2. , both ends of the casing 2 are exposed outside the water main pipe 1 .

[0020] As shown in Figures 3 and 4, the two ends of the water main pipe 1 respectively have a water inlet pipe section 1-2 and a water outlet pipe section 1-3 whose outer diameter is smaller than the outer diameter of the pipe section in the middle of the water main pipe 1.

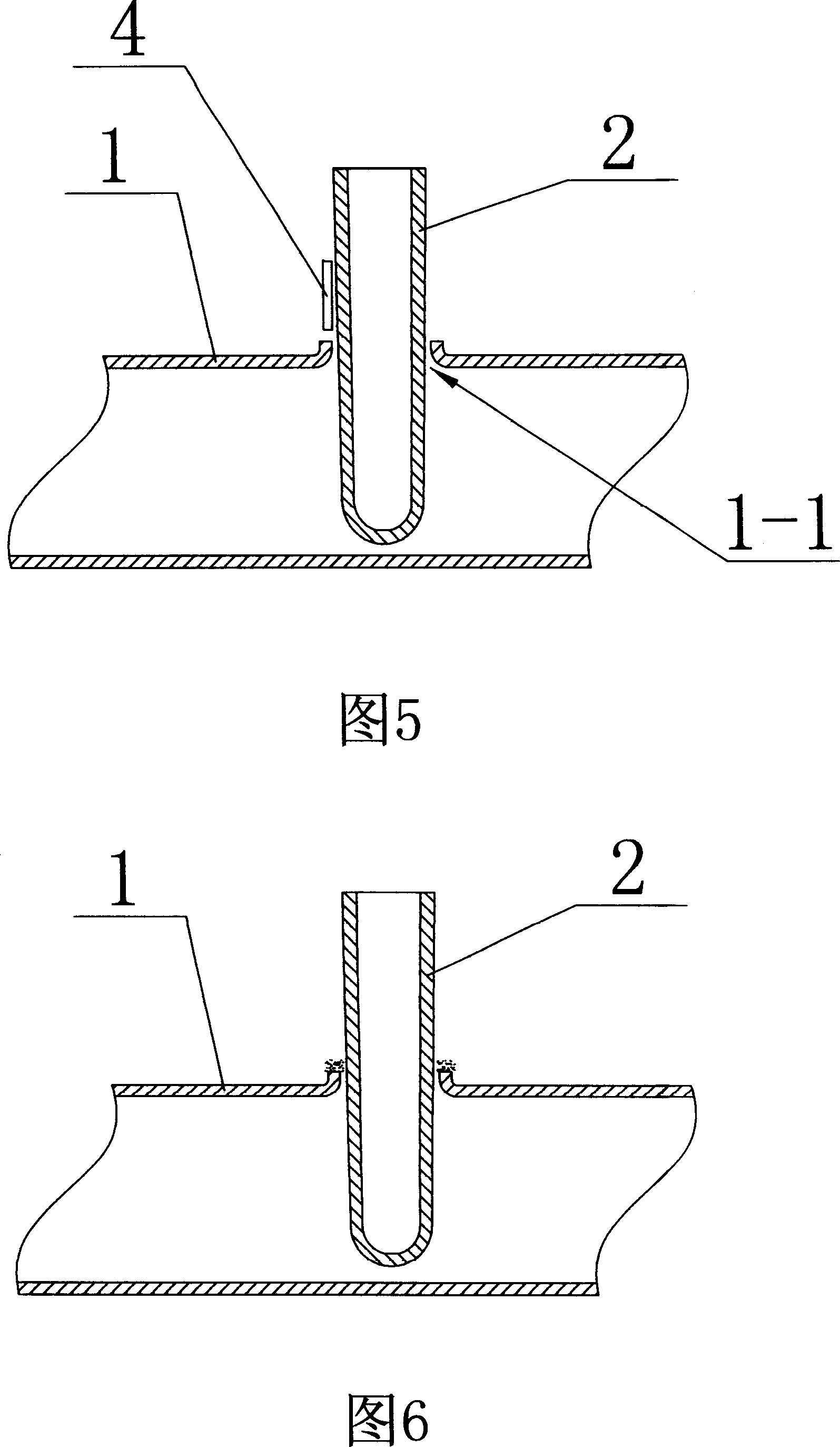

[0021] As shown in Figures 5 and 6, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com