Device for enhancing shell strength during heat exchanger tube head pressure withstanding test and pressure testing method

A heat exchanger tube, pressure test technology, used in the application of stable tension/pressure to test the strength of materials, measuring devices, testing of machinery/structural parts, etc., can solve personnel poisoning, ammonia and air explosions, ammonia Air leakage environment and other problems, to achieve the effect of increasing the strength of the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

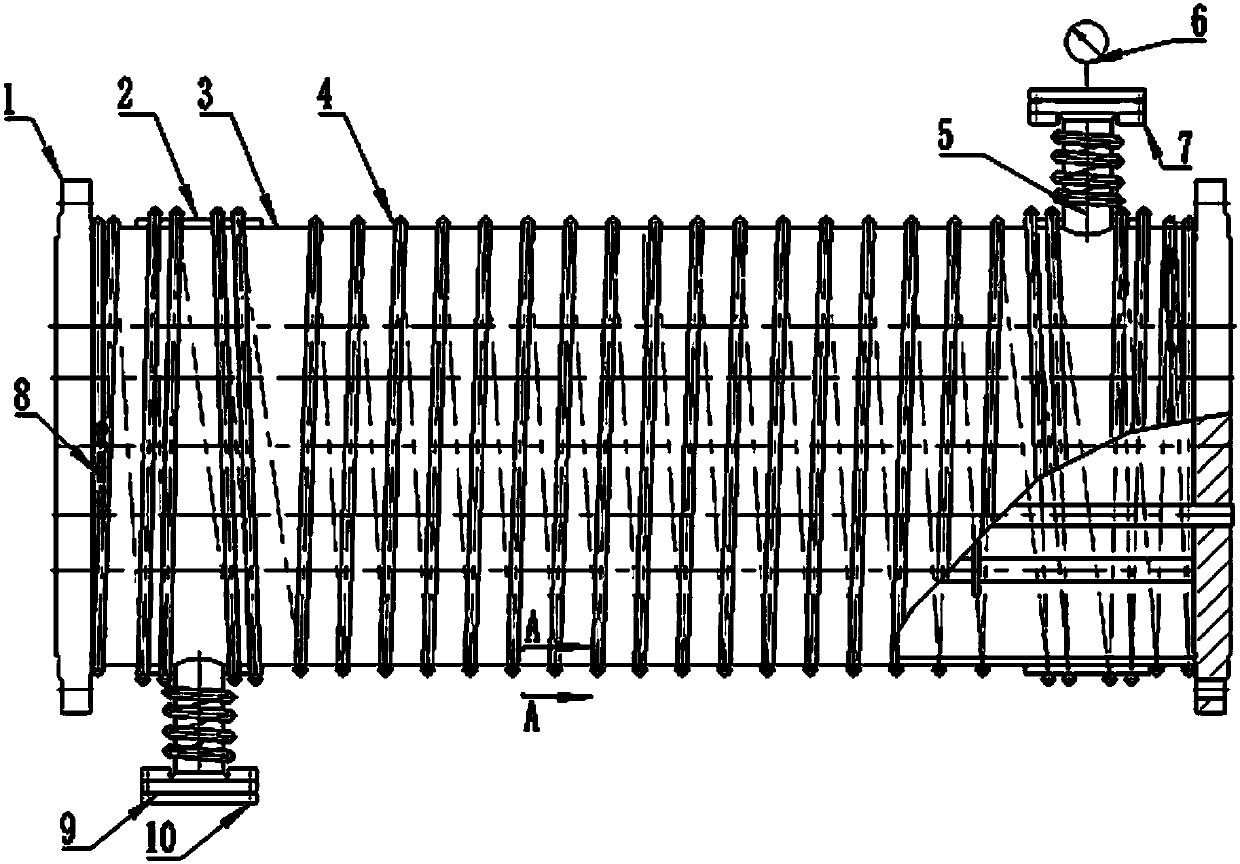

[0037] Such as figure 1 As shown, a device for enhancing the strength of the shell during the pressure test of the heat exchanger tube head is used for the pressure test process of the tube head of the fixed tube sheet heat exchanger, and is arranged on the heat exchanger shell 3,

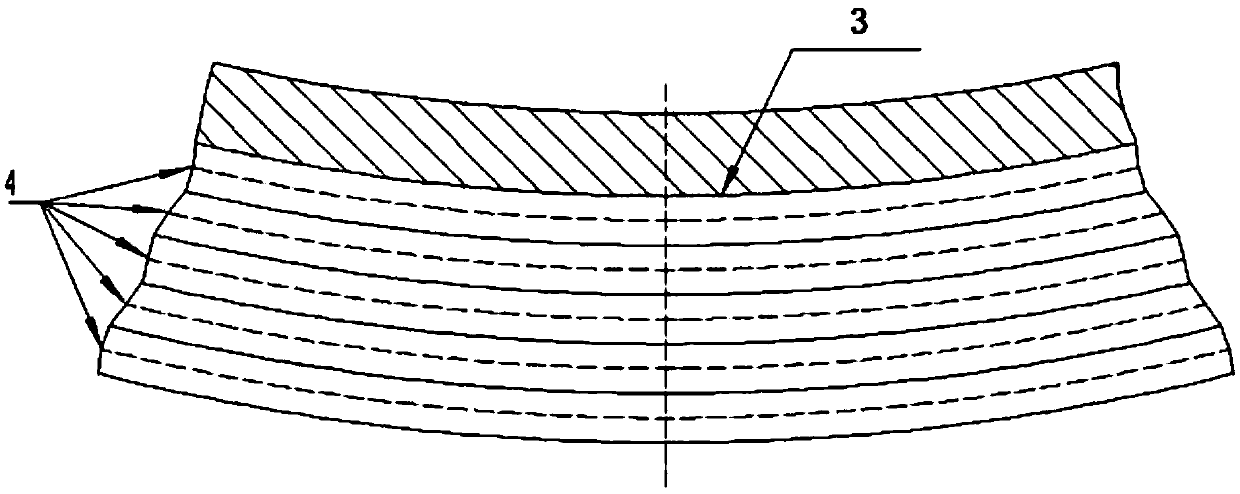

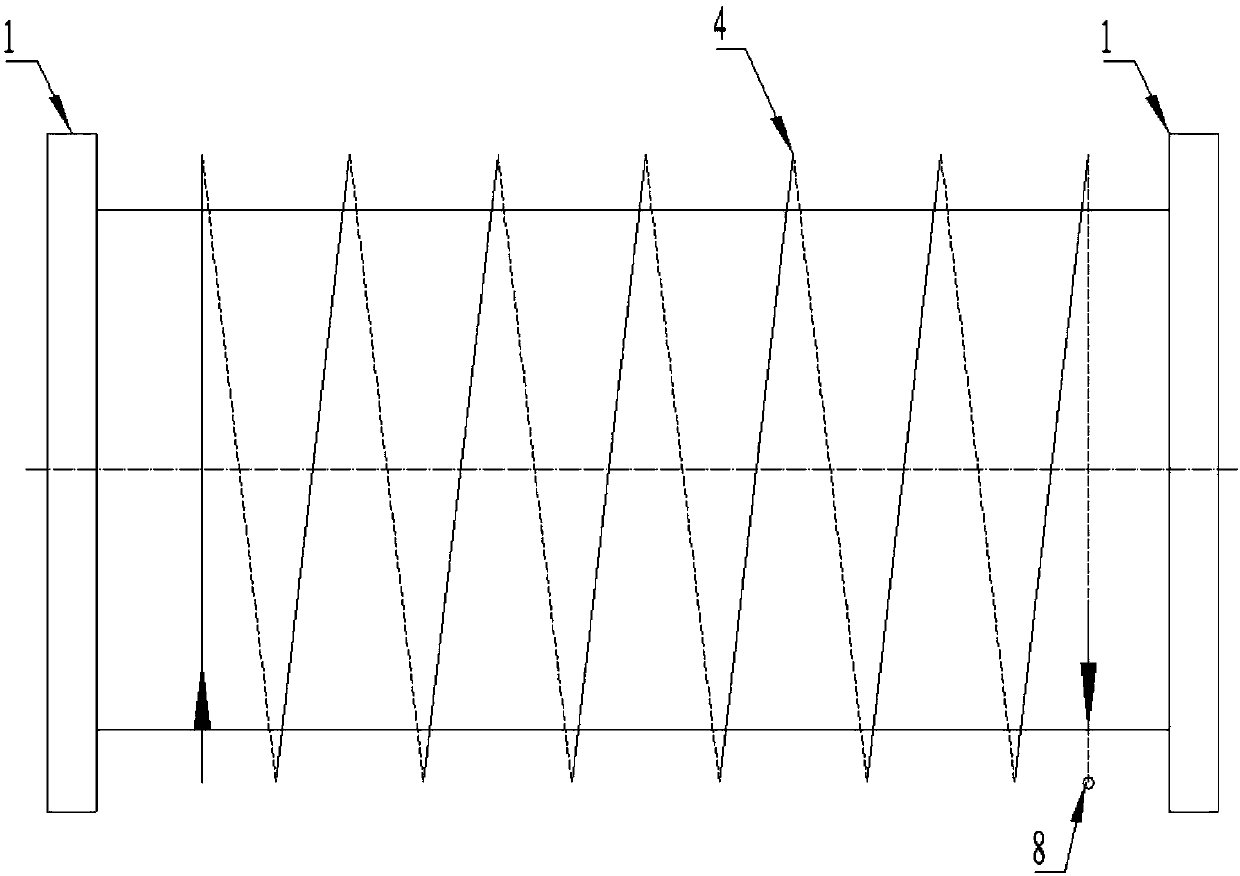

[0038] A connecting pipe fitting 5 is fixedly connected to the side wall of the heat exchanger housing 3, and a blind zone reinforcing ring 2 is arranged on the circumference of the joint between the heat exchanger housing 3 and the connecting pipe fitting 5, and the flange on the connecting pipe fitting 5 A flange rigidity reinforcing ring 7 is fixedly arranged on the back, a blind plate is fixed on the flange connecting the pipe fitting 5, and a pressure gauge assembly 6 is fixedly arranged on the blind plate, and the heat exchanger shell 3, the blind area reinforcing ring 2, A number of flexible ropes 4 are wound on the connecting pipe fitting 5 to increase strength, and the winding direction is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com