Nitrogen protection anti-explosion device and method of converter flue gas waste heat boiler

A waste heat boiler and converter flue gas technology, which is applied in the field of converter flue gas waste heat boiler, can solve problems such as the influence of converter steelmaking production order, the decline of equipment sealing performance, and the high cost of maintenance and repair, so as to prevent major safety production accidents and reduce Effects of maintenance and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

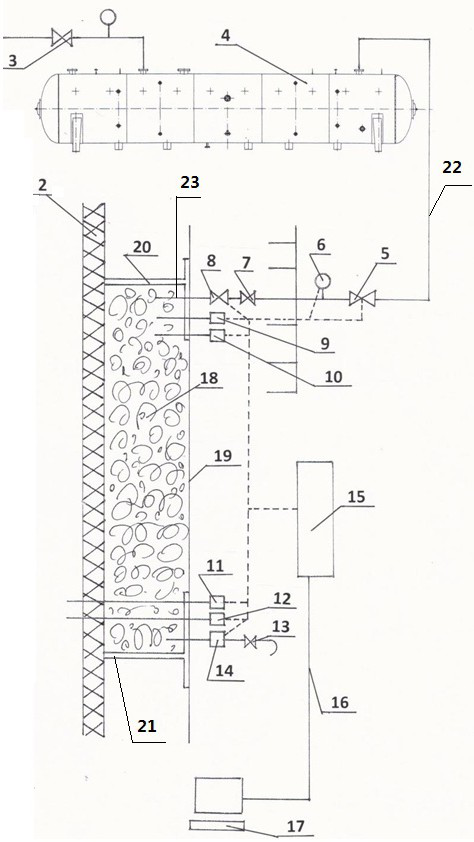

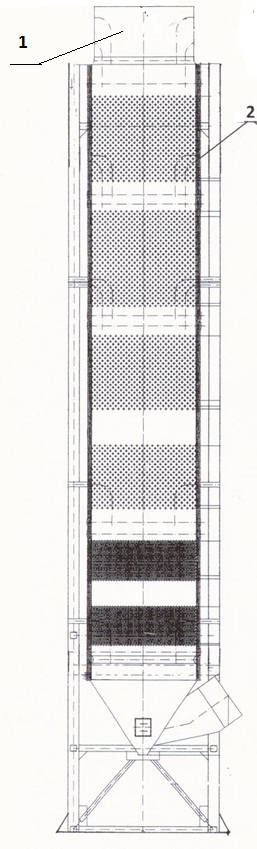

[0022] A nitrogen protection explosion-proof device for converter flue gas waste heat boiler, comprising waste heat boiler outer wall 2, nitrogen storage tank 4, nitrogen main pipe pressure regulating valve 5, nitrogen main pipe pressure transmitter 6, branch pipe valve 7, branch pipe solenoid valve 8, protective layer nitrogen Pressure transmitter 9, protective layer temperature transmitter 10, converter flue gas waste heat boiler flue gas temperature transmitter 11, converter flue gas waste heat boiler flue gas pressure transmitter 12, oxygen sensor 14, programmable controller 15, Communication cable 16, computer monitor 17, protective layer insulation material 18, outer sealing layer 19, outer upper bracket 20 and outer lower bracket 21; at least one set of outer upper bracket 20 and outer lower bracket are arranged on the outer circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com