Flexible silica aerogel material and preparation method thereof

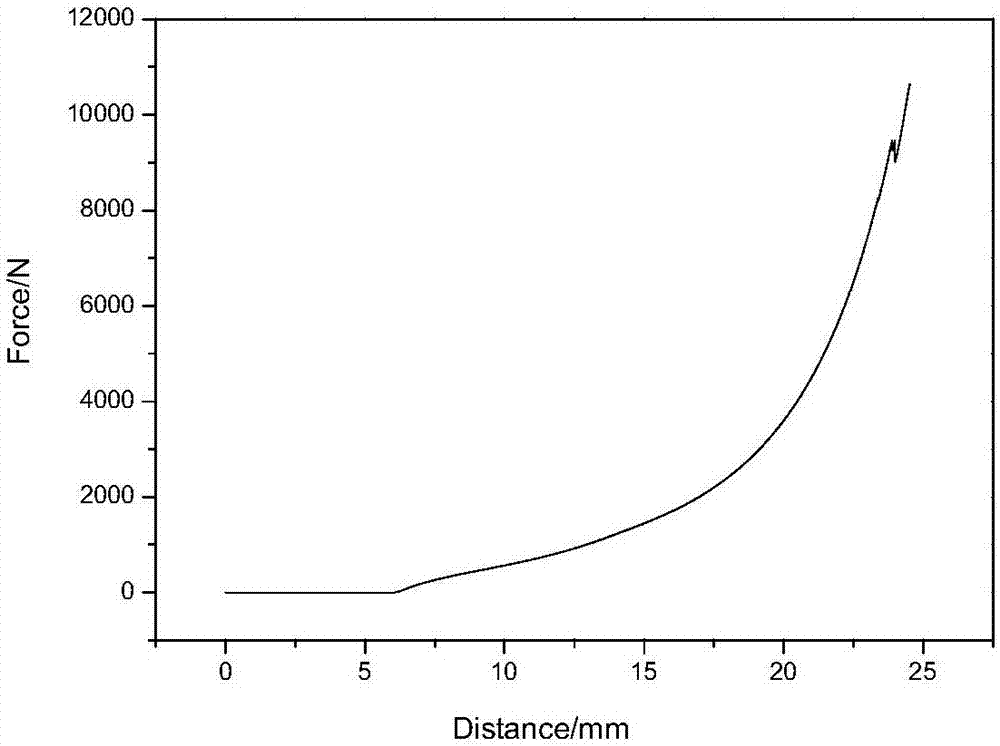

A technology of silica airgel and silica sol, which is applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of low strength, falling powder particles, large brittleness, etc., to expand the scope of application, Effects of improved service life and good deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a method for preparing a flexible silica airgel material, comprising the following steps:

[0037] 1) Freezing the acidic silica sol to obtain frozen silica sol;

[0038] The purpose of freezing the acidic silica sol is to reduce the rate of the subsequent reaction of the silica sol with the amino group-containing silane coupling agent, so as to reasonably modify the surface of the silica sol with amino groups;

[0039] In the embodiment of the present invention, by sealing the acidic silica sol, at -10 - Place it at -20°C for 60-80 minutes to obtain frozen silica sol.

[0040] If the freezing temperature is lower than -20°C, it is possible to prolong the subsequent gelation time. If the temperature is higher than -10°C, the polycondensation rate of the subsequent silica sol cannot be well controlled. Under the temperature and time conditions of the present invention, silica The gelation time of the sol is about 5-8 min...

Embodiment 1

[0061] First, pour tetraethyl orthosilicate, deionized water, hydrochloric acid and ethanol into a beaker, and stir in water at a temperature of 50°C for 30 minutes to obtain an acidic silica sol. Among them, tetraethyl orthosilicate, deionized water, hydrochloric acid , The molar ratio of ethanol is: 1:2:0.001:15;

[0062] Then, seal the silica sol, put it in the refrigerator, adjust the temperature to -20°C, and store it for 60 minutes to obtain frozen silica sol;

[0063] Add aminopropyltriethoxysilane to the above frozen silica sol, the molar ratio of aminopropyltriethoxysilane to tetraethyl orthosilicate is 0.1:1, stir at room temperature for 3 minutes, then pour into the mold In the process, after the mold was sealed, it was aged at room temperature for 2 days to form a surface amino-modified silica wet gel;

[0064] Slowly pour out the wet gel from the abrasive tool, soak it into the tetrahydrofuran solution containing bisphenol A diglycidyl ether, wherein the molar am...

Embodiment 2

[0069] First, pour ethyl orthosilicate, deionized water, hydrochloric acid, and ethanol into a beaker, and stir in water at a temperature of 50°C for 20 minutes to obtain an acidic silica sol. Among them, ethyl orthosilicate, deionized water, hydrochloric acid, and ethanol The molar ratio is: 1:3:0.001:20; then seal the silica sol, put it in the refrigerator, adjust the temperature to -20°C, and store it for 60 minutes to obtain frozen silica sol;

[0070] Add aminopropyltriethoxysilane to the above frozen silica sol, the molar ratio of aminopropyltriethoxysilane to ethyl orthosilicate is 0.2:1, stir at room temperature for 5 minutes, then pour into the mold In the process, after the mold was sealed, it was aged at room temperature for 3 days to form a surface amino-modified silica wet gel;

[0071] Slowly pour out the wet gel from the abrasive tool, soak it into the tetrahydrofuran solution containing bisphenol A diglycidyl ether, wherein the molar amount of bisphenol A digly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com