High-pressure airless spray gun without blind spraying corner

A high-pressure airless spray gun, no spraying technology, applied in the direction of spraying device, single handheld device, etc., can solve the problems affecting the quality stability and consistency of workpiece spraying, achieve economical and reasonable work efficiency, stable force, and range of use wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The high-pressure airless spray gun without spraying dead angle of the present invention is described in detail below in conjunction with accompanying drawing:

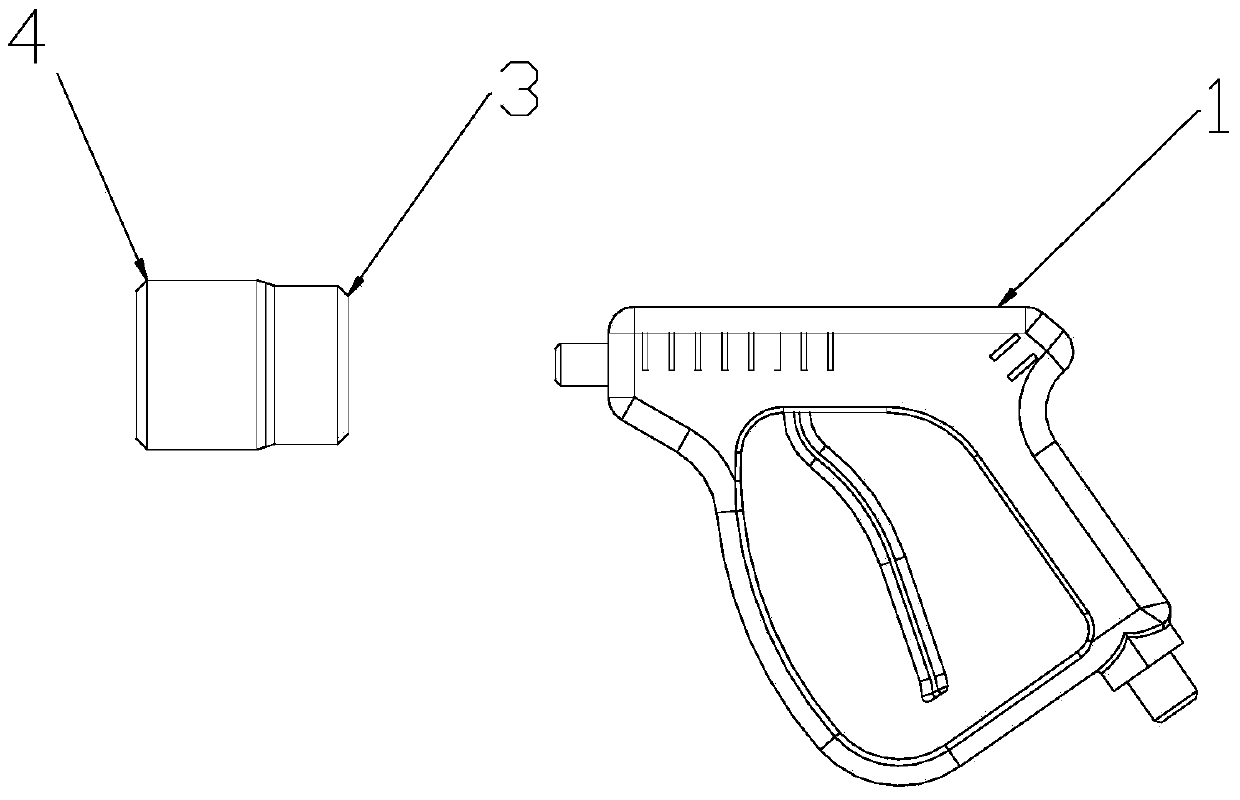

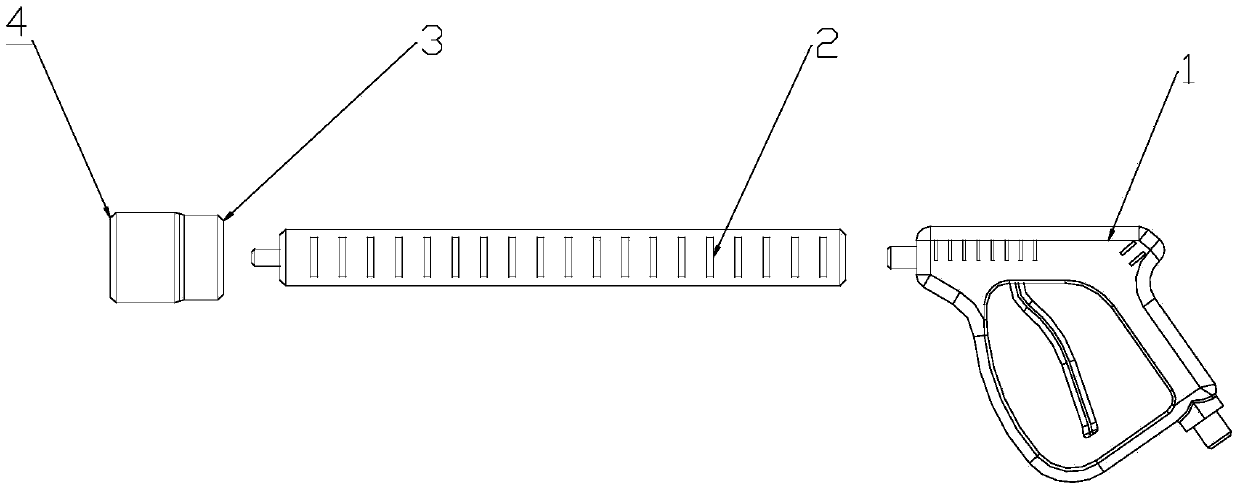

[0027] Such as figure 1 As shown, the high-pressure airless spray gun without spraying dead angle of the present invention includes an assembly consisting of a gun handle 1, a pressure regulating valve 3 and a high-pressure nozzle 4. Among them, high-pressure nozzles are divided into two types: circular nozzles and fan nozzles.

[0028] The high-pressure airless spray gun without spraying dead angle of the present invention also includes a diaphragm pump (omitted and not shown in the figure) driven by a motor. When the spray gun performs spraying operations, the static pressure generated by the diaphragm pump is used as the driving force for paint spraying. Spray paint directly onto the workpiece surface.

[0029] Such as figure 2 As shown, the high-pressure airless spray gun without spraying dead angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com