Intelligent electrically-driven cable arranging device of marine winch

A technology of electric drive and cable unwinding device, which is applied in the direction of clockwork mechanism and hoisting device, etc. It can solve the problems of winch structure impact, difficulty in changing cable unwinding stroke, poor real-time performance, etc., and achieves increased drum length and good cable unwinding effect , the effect of long cable distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a clear and complete description of the technical solution of the present invention through the embodiments in conjunction with the accompanying drawings, in order to help further understand the present invention, but not to limit it. The described embodiment is only a preferred implementation of the present invention, and within the spirit and principle of the present invention, various replacements and modifications shall be included in the protection scope of the present invention.

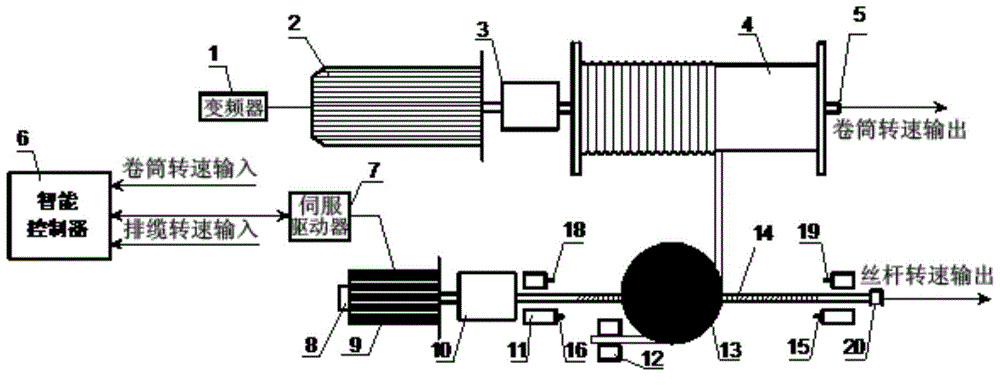

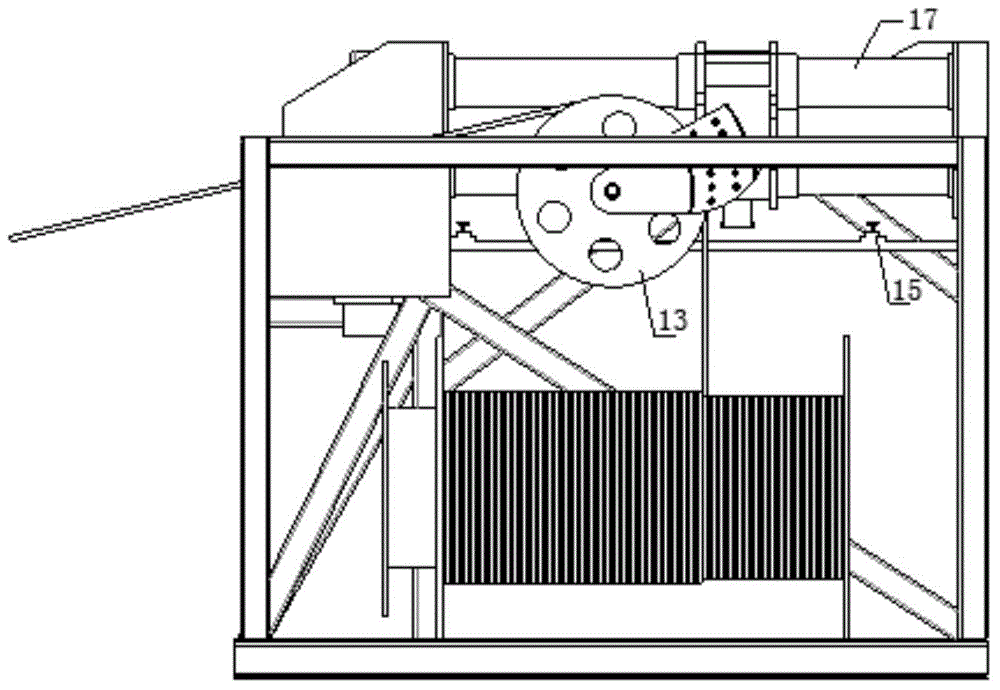

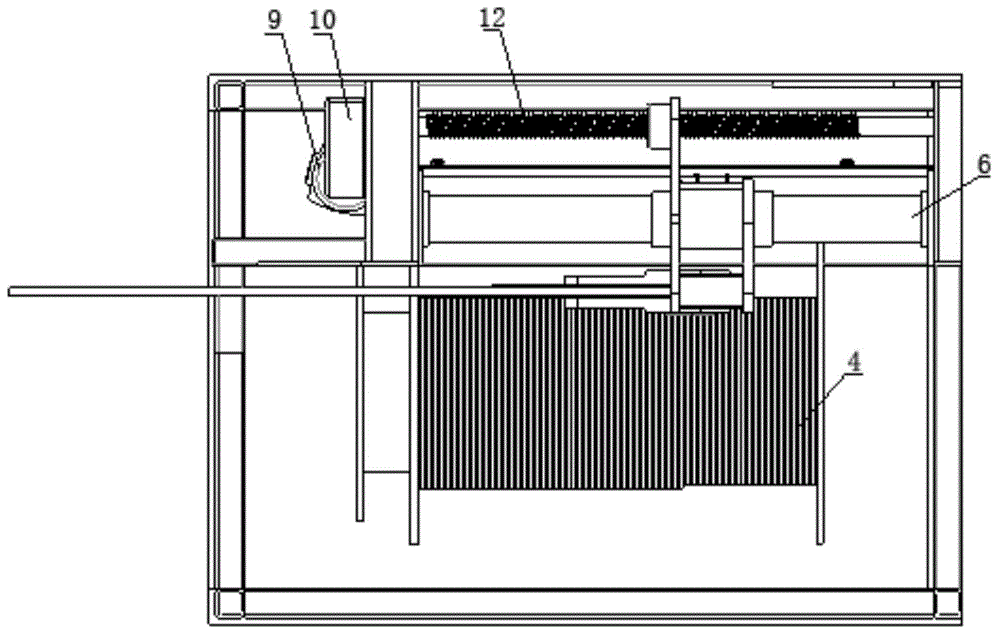

[0022] Such as figure 1 , 2 , 3, and 4, the intelligent cable arrangement of the electrically driven marine winch of the present invention includes a frequency converter 1, a three-phase asynchronous motor 2, a planetary reducer 3, a drum 4, a drum speed detection photoelectric encoder 5, and an intelligent controller 6 , AC servo driver 7, motor speed photoelectric encoder 8, permanent magnet synchronous motor 9, reducer 10, bearing 11, line width sensor 12, fairlead 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com