Special integrated production device for furniture parts

A technology for producing devices and parts, applied in the field of furniture parts production and processing equipment, can solve the problems of integrated processing of furniture parts without preliminary molding, difficulty in ensuring the surface uniformity of furniture parts, and difficulty in ensuring the processing effect, etc. The effect of wide application range, shortened processing time, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

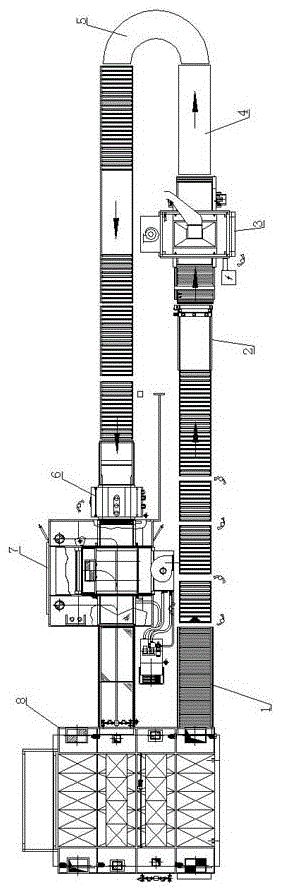

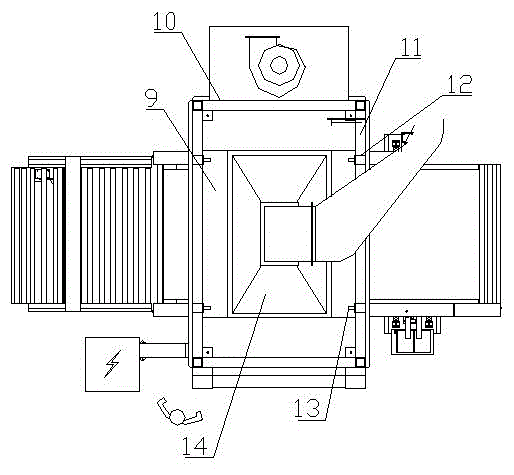

[0018] Embodiment 1, with reference to figure 1 and figure 2 , an integrated production device dedicated to furniture parts, including a frame and a feeding track 1 arranged on the frame, one end of the feeding track 1 is a feeding end, and the other end of the feeding track 1 is a discharging end, from The first dust removal device 2, the color repair device 3, the drying device 4, the second dust removal device 6, the paint spraying device 7 and the drying bin 8 are successively arranged at intervals on the feeding track 1 from the feed end to the discharge end; Both the first dedusting device 2 and the second dedusting device 6 comprise a casing, in which two brush rollers arranged parallel to the feeding track 1 are arranged, the two brush rollers are arranged front and back along the feeding direction, and the casing above the brush rollers is provided with Dust suction device is arranged; Described color repairing device 3 and paint spraying device 7 all comprise the s...

Embodiment 2

[0019] Embodiment 2, in the integrated production device dedicated to furniture parts described in Embodiment 1: two spray guns 13 in each group are symmetrically arranged on the two outer sides of the moving seat.

Embodiment 3

[0020] Embodiment 3, in the integrated production device dedicated to furniture parts described in Embodiment 1: the distance between the spray gun 13 and the painting table 9 is 180 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com