Avermectin extraction technology and apparatus

A technology of abamectin and extraction method, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of excessive leakage of plate and frame filter solvents, health hazards of employees, and heavy odors in the production environment. Achieve the effect of benefiting the health of employees, reducing solvent loss, and reducing material transfer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

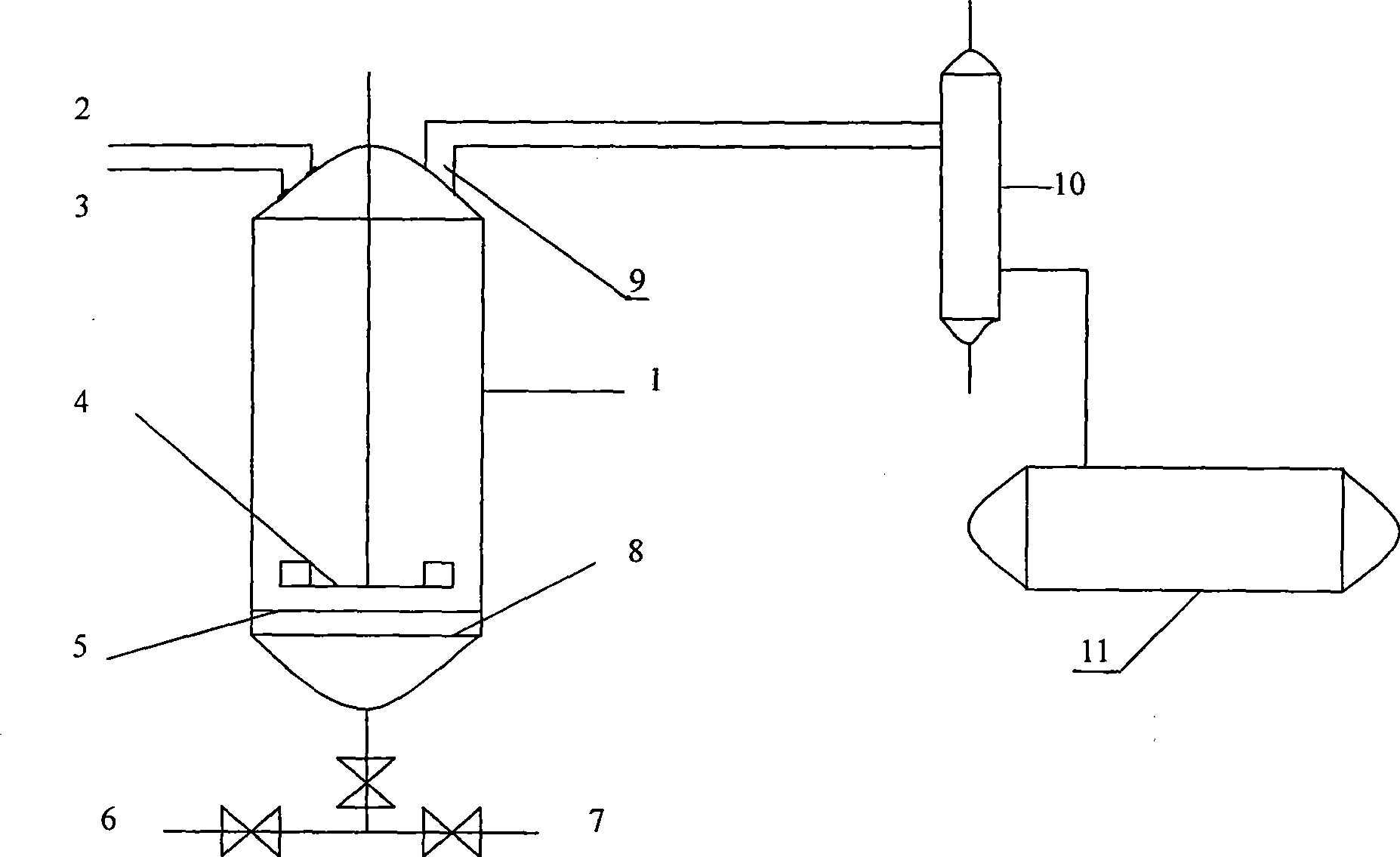

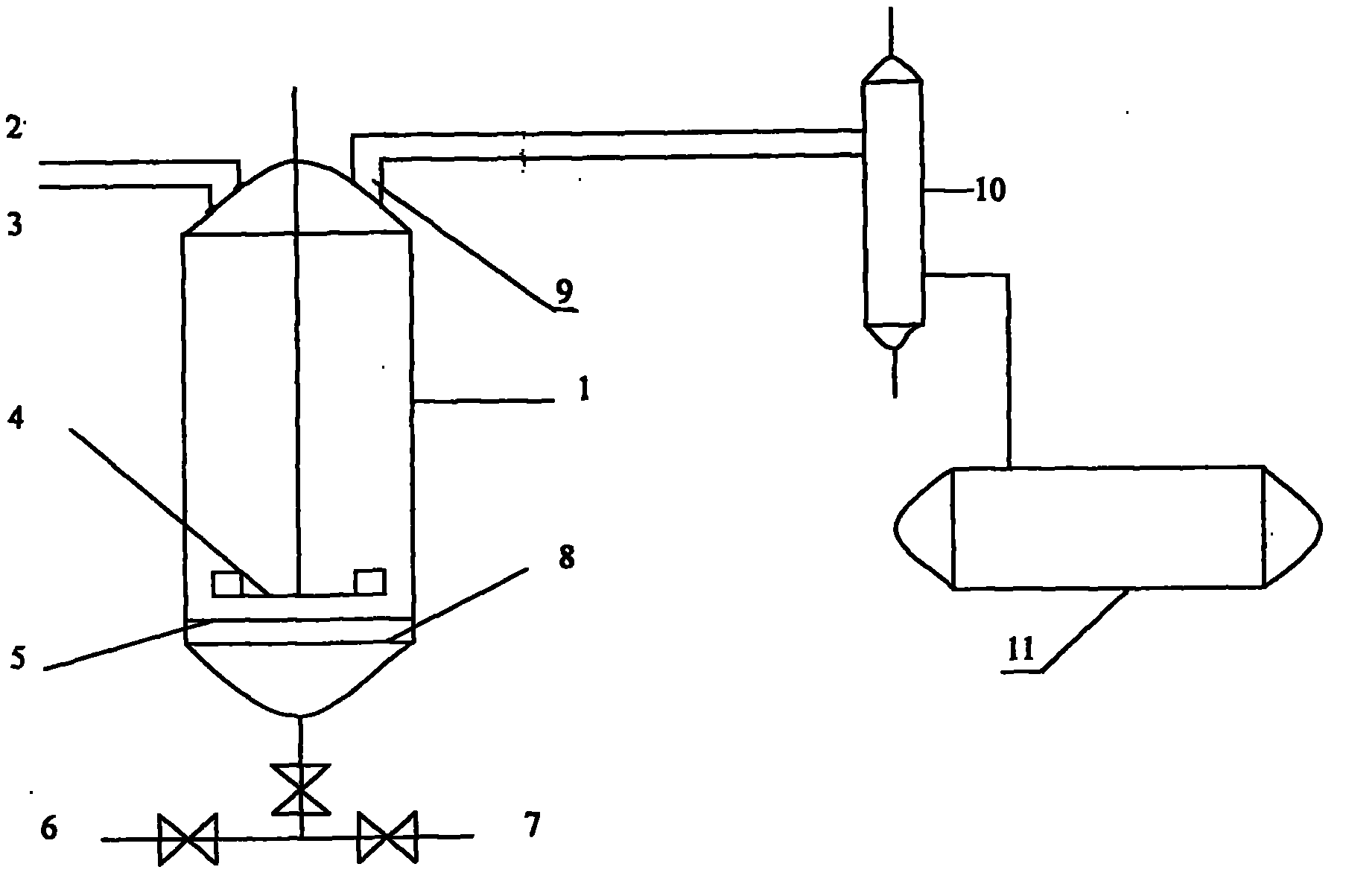

[0029] Embodiment 1. A kind of special extraction column of Abamectin extraction technology

[0030] The structure of the extraction column is as follows figure 1 As shown, the extraction column is a closed tank container 1, and a stirrer 4 is arranged in the closed tank container 1. There are alcohol inlet 2 and nitrogen inlet 3 on the top of the airtight tank container, alcohol inlet 2 is used to add methanol or ethanol, there is a sieve plate 8 on the lower head of the container, a filter cloth 5 is laid on the sieve plate, and an extraction solution is provided at the bottom of the container Outlet 7 and steam inlet 6, alcohol gas outlet 9 is provided at the top of the container, and a condenser 10 is connected to the alcohol gas outlet. The condenser 10 is connected with an alcohol collection tank 11 for collecting recovered methanol or ethanol. The leach solution outlet is used to collect the leach solution, and the alcohol gas outlet and condenser are used to recover ...

Embodiment 2

[0031] Embodiment 2: Abamectin extraction

[0032] Put 2000 kilograms of dried abamectin mycelium into the extraction column, add 2M 3 Soak in methanol for 1-2 hours, then 1-1.5M per hour 3 The flow rate is to add methanol from the alcohol inlet 2 at the top of the column, and the effluent is collected at the bottom extraction liquid outlet 7 to enter the next step. When the output reaches 5-8M 3 When , collect the effluent in a set container. When the output reaches 15M 3 When, start to detect the abamectin content of the effluent at 120u / ml, 16M 3 Continue to detect the content at 90u / ml, stop feeding, use nitrogen to press out the methanol in the leaching column, and then pass steam from the steam inlet 6 at the bottom of the leaching column, and the methanol gas enters the external condenser from the alcohol vapor outlet 9 at the top 10 Collect methanol.

Embodiment 3

[0033] Embodiment 3: Abamectin extraction

[0034] Put 1500 kilograms of dried abamectin mycelia into the extraction column, add 3M 3 Soak in methanol for 1-2 hours, then 1-1.5M per hour 3 The flow rate is to add methanol from the alcohol inlet 2 at the top of the column, and the effluent is collected at the bottom extraction solution outlet 7 to enter the next step. When the output reaches 4-6M 3 When , collect the effluent in a set container. When the output reaches 10M 3 At the time, the avermectin content in the effluent was detected at 110u / ml, 12M 3 Continue to detect the content at 80u / ml, stop feeding, use nitrogen to press out the methanol in the leaching column, then pass steam from the bottom of the leaching column, and the methanol gas enters the external condenser from the top end alcohol vapor outlet 9 to collect methanol .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com