Filling system for preassembled module type flusher

A filling system, modular technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of restricting production efficiency, leakage of liquid outlet, easy to be polluted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated by the following examples.

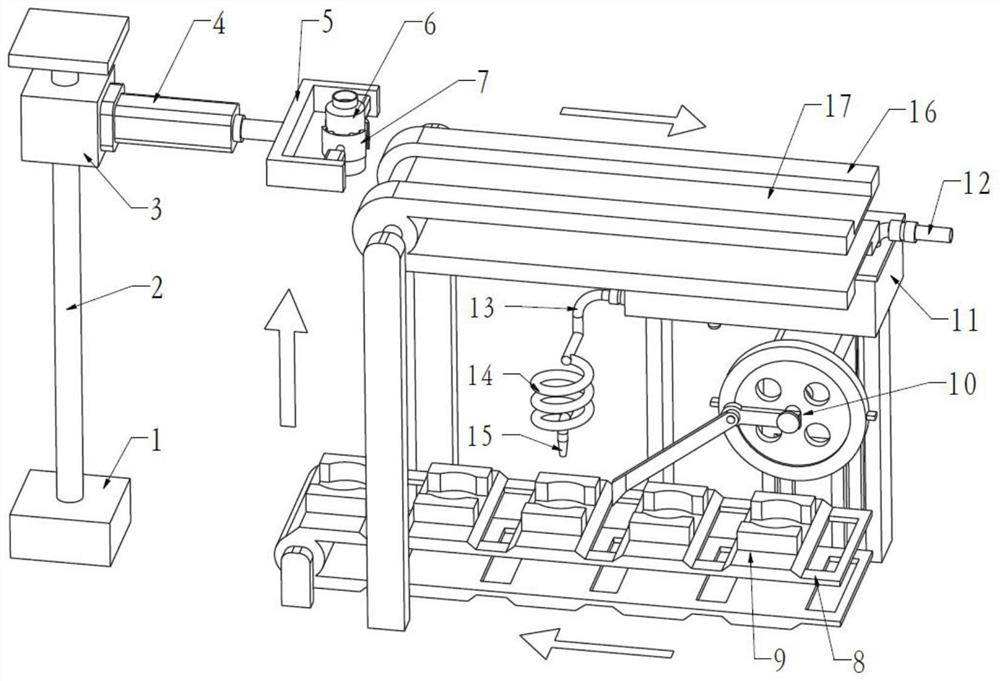

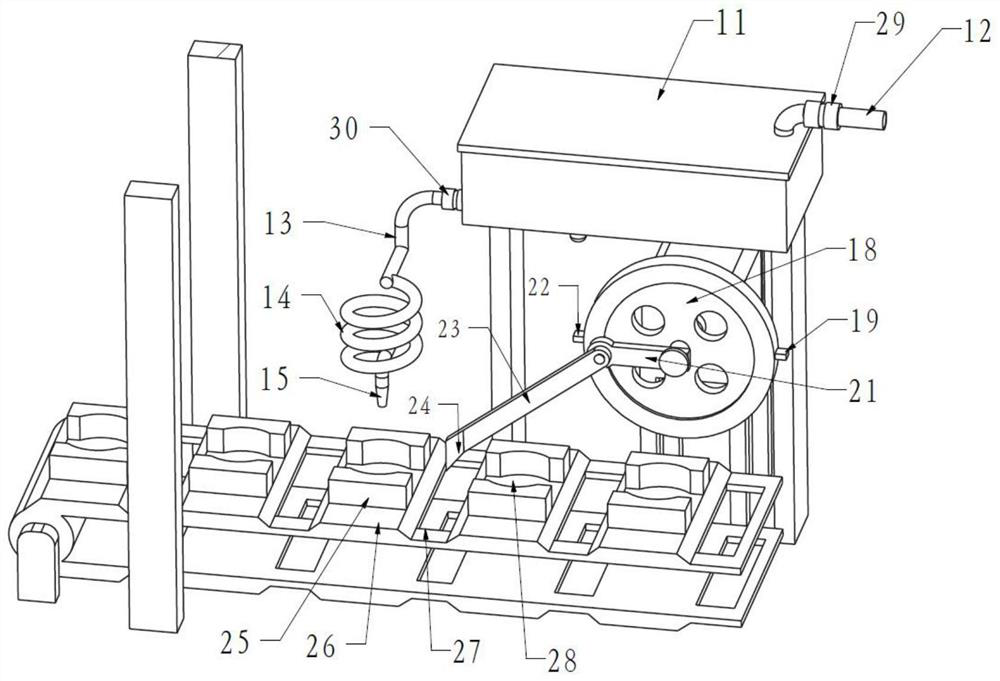

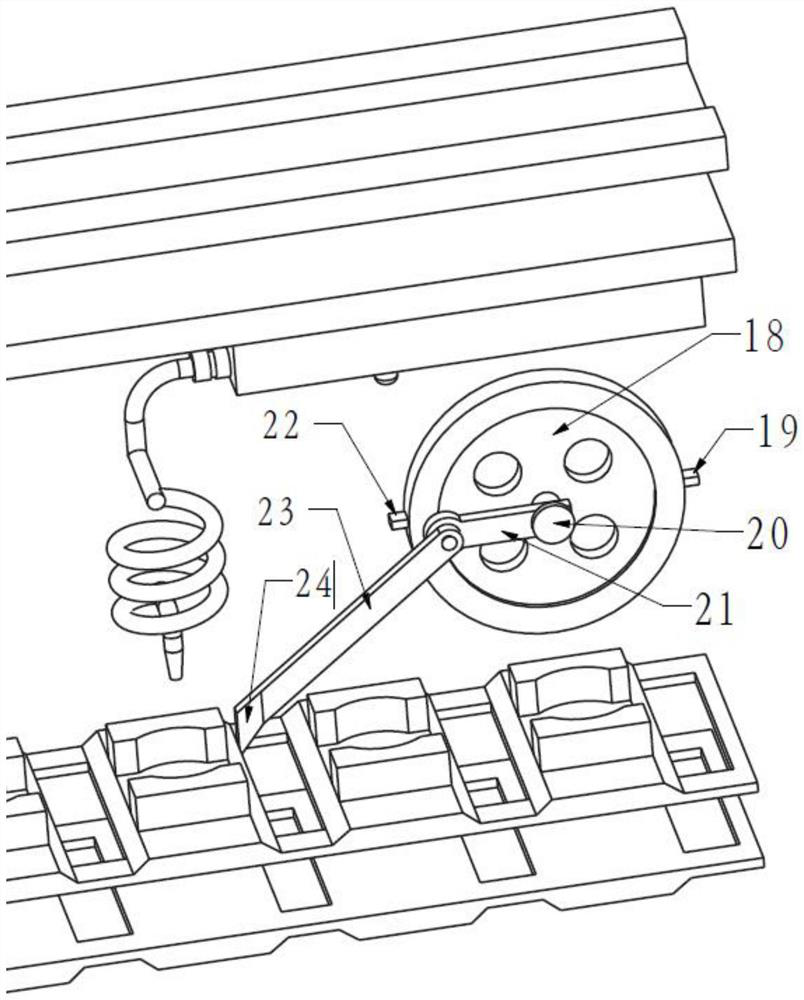

[0036] A filling system for a pre-installed modular flusher, comprising a feed conveyor belt 8 and a discharge conveyor belt 17, the feed conveyor belt 8 is located below the discharge conveyor belt 17, the feed conveyor belt 8 and the discharge conveyor belt 17 A vertical tubular linear motor 1 is arranged on one side, and the mover 3 of the tubular linear motor 1 is connected with a bottle clamping mechanism. part 9, the feeding conveyor belt 8 is located between each bottle body limiting part 9 and has a slot 27; the upper side of the feeding conveyor belt 8 is provided with an interval pushing device 10, and the interval pushing device 10 includes a turntable 18 , the rotating shaft 20 of the turntable 18 is connected with a pendulum push mechanism to cooperate with the slot hole 27 to push the feed conveyor belt 8 at intervals; the top of the feed conveyor belt 8 is provided with a liquid sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com