Patents

Literature

51results about How to "Improve transfer power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

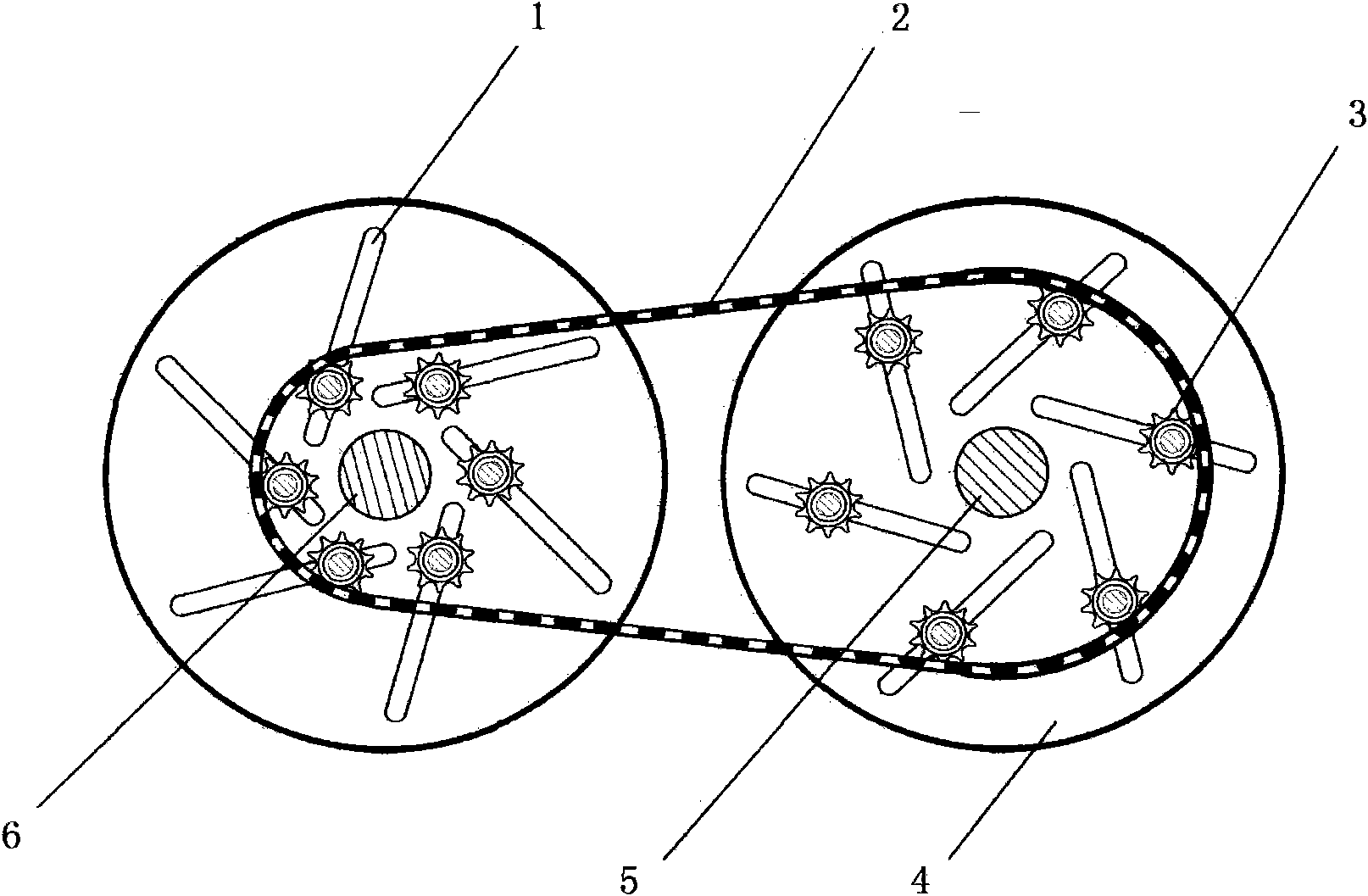

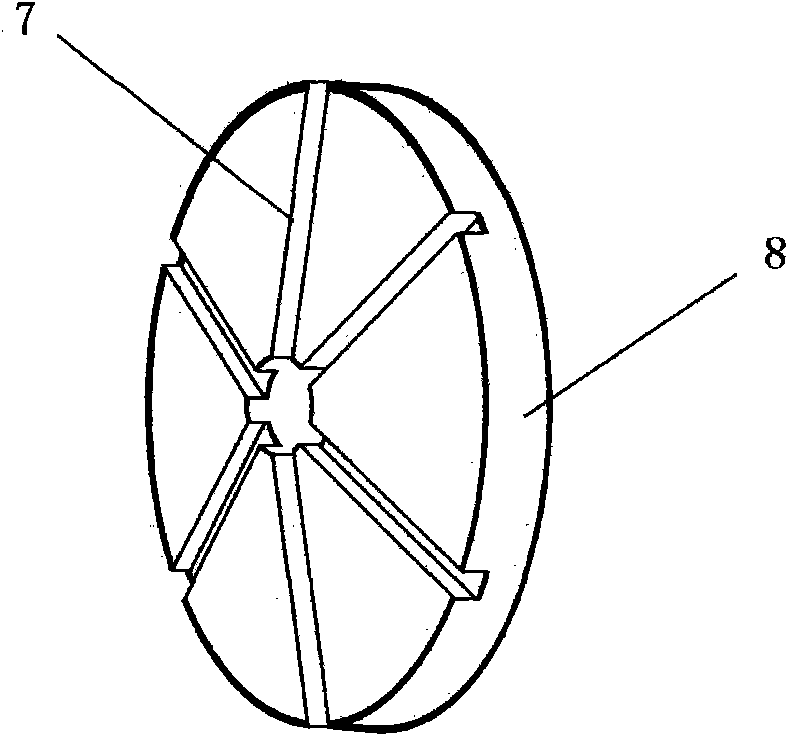

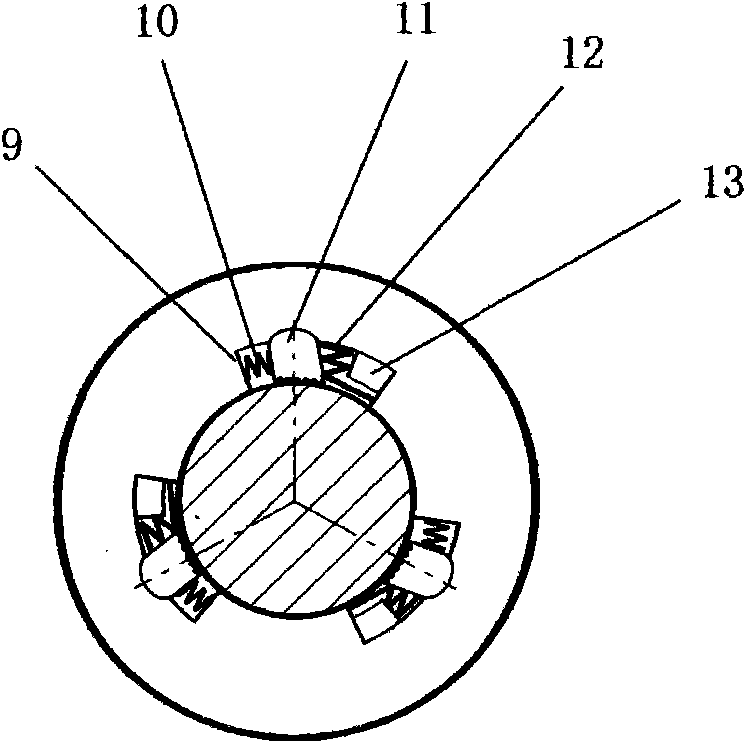

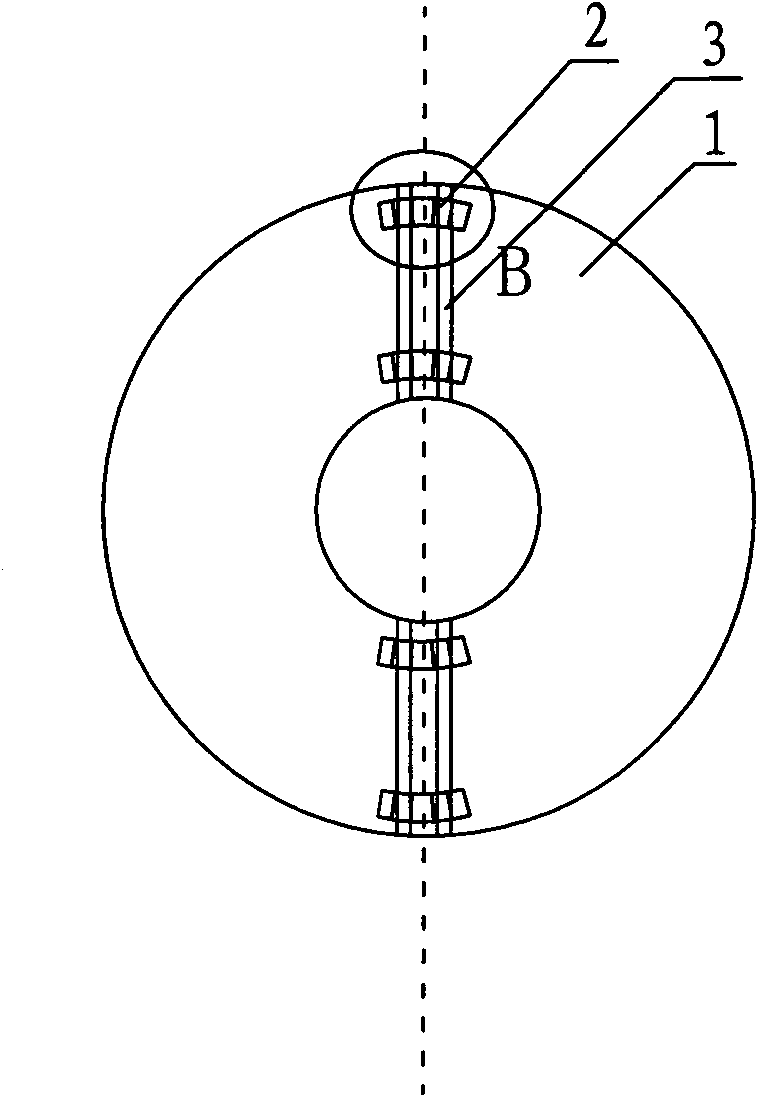

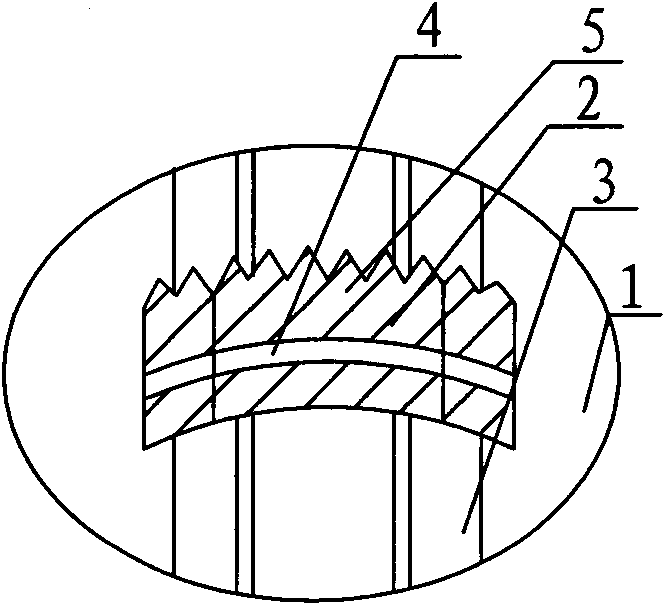

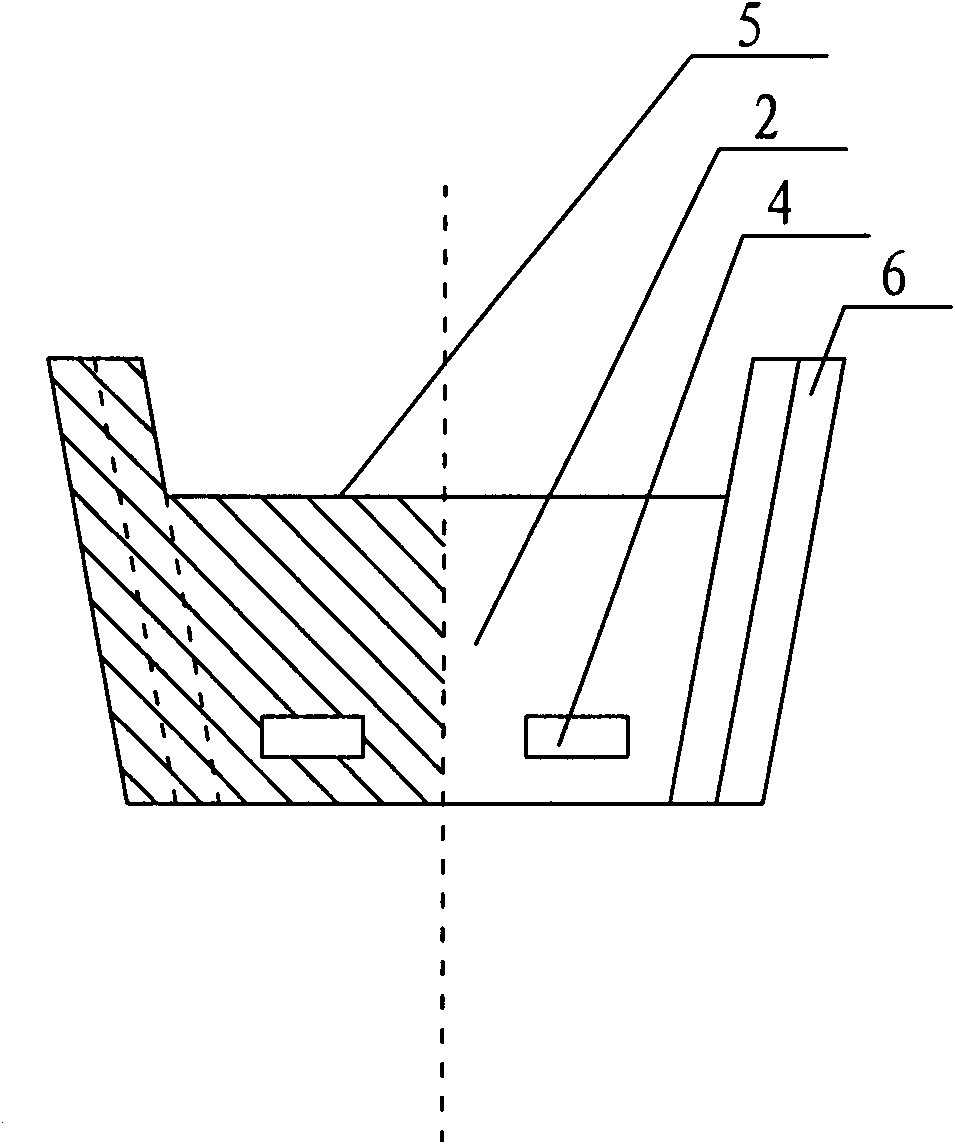

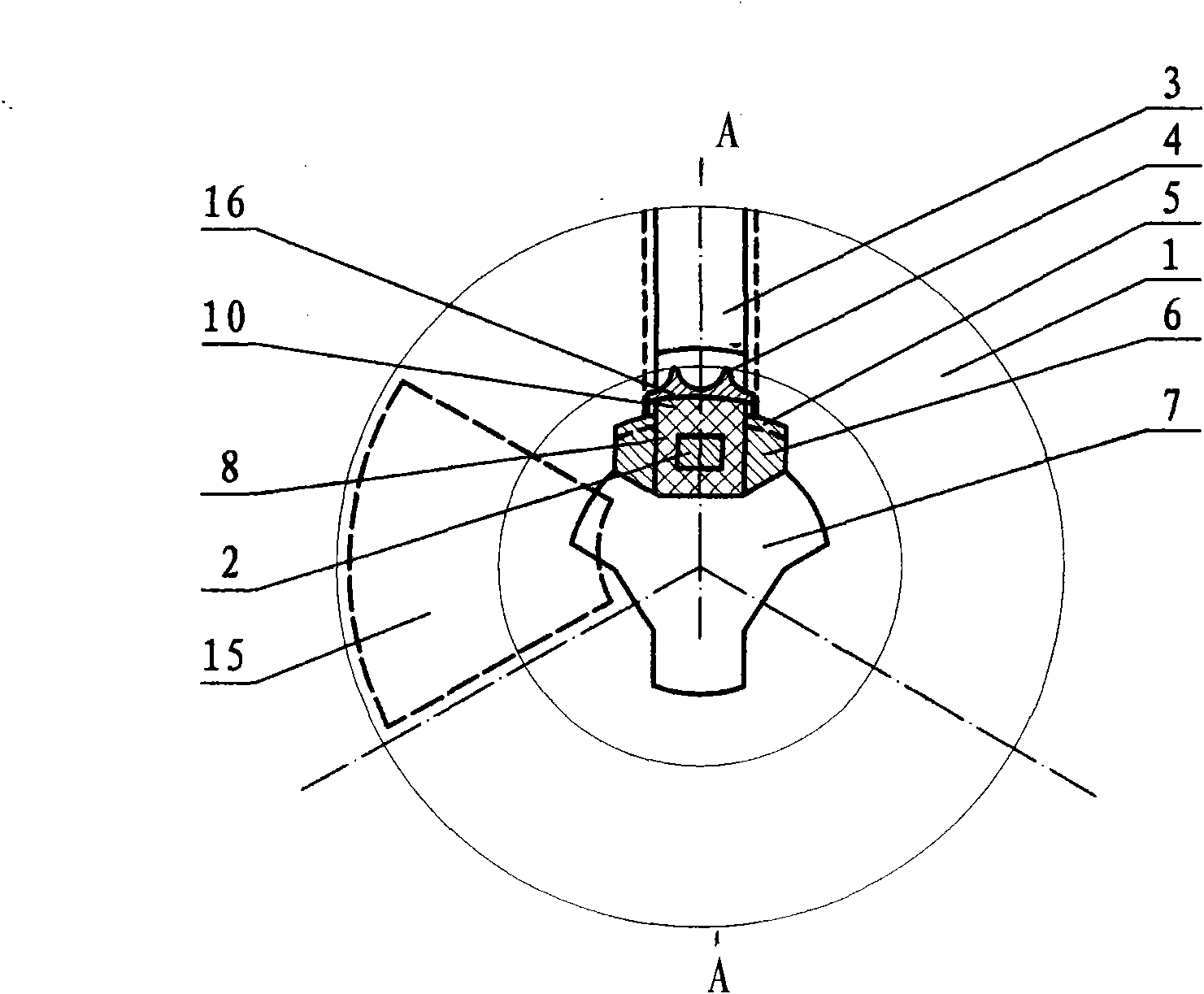

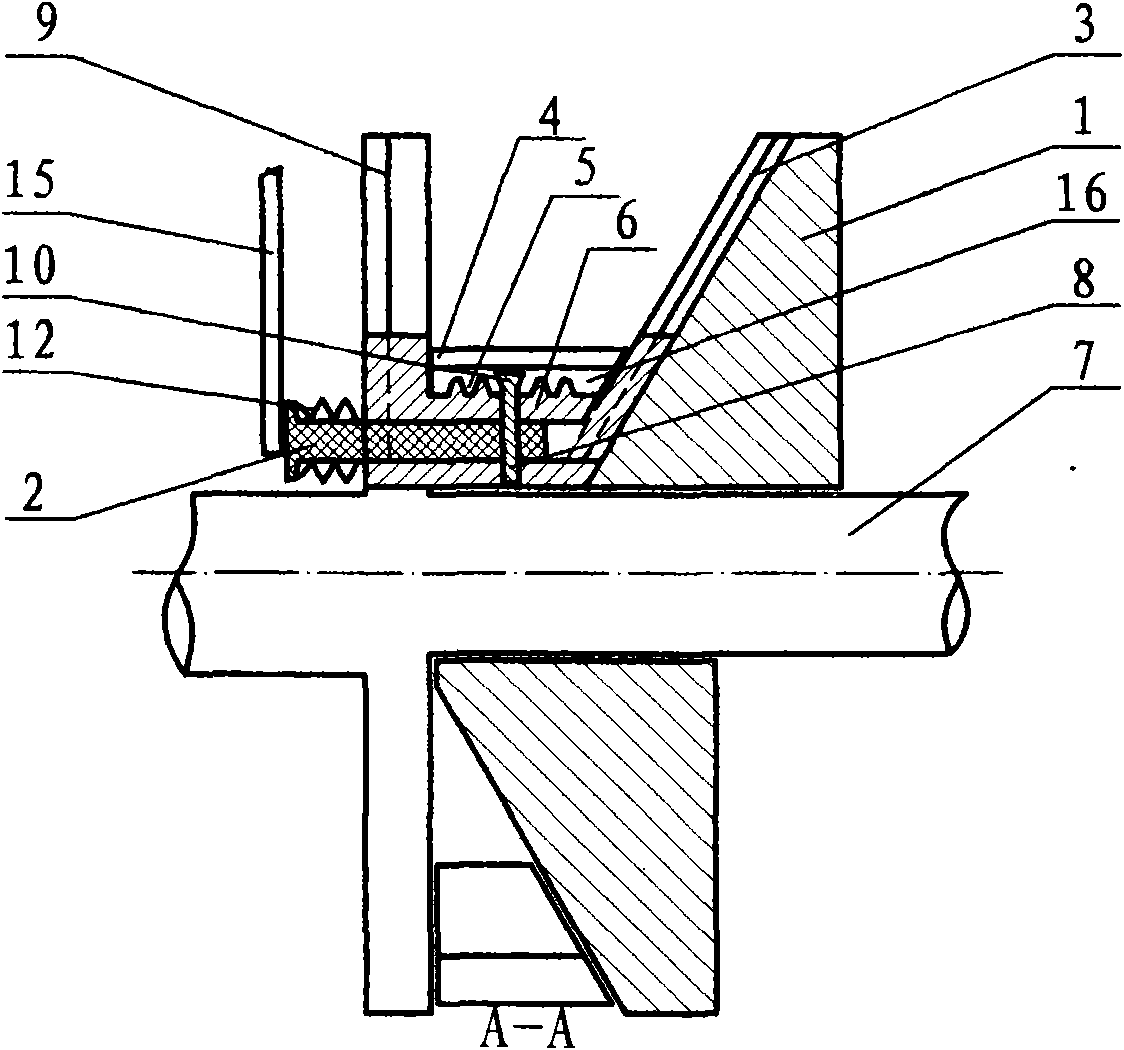

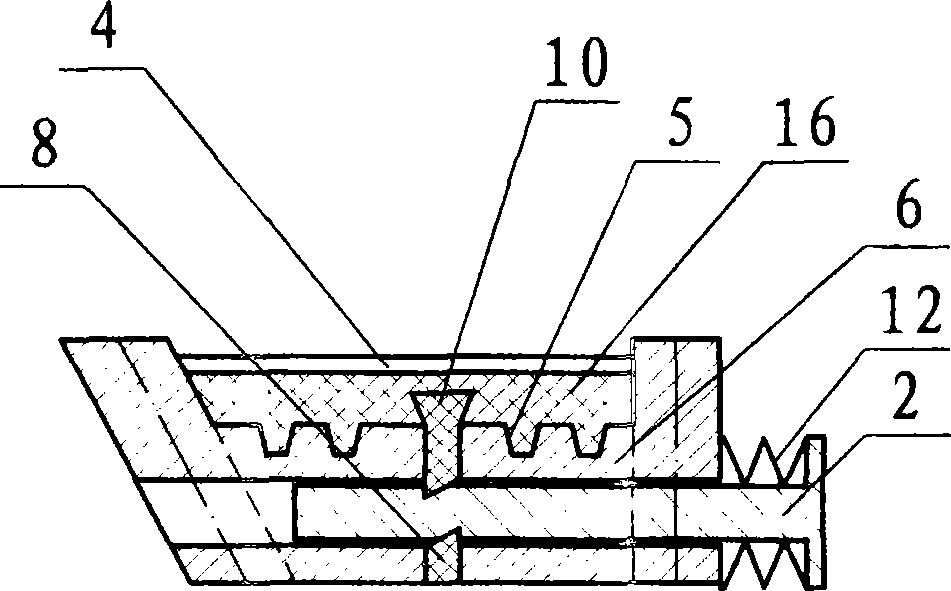

High-power stepless transmission

The invention relates to a tooth chain type stepless transmission for an automobile. A tooth chain is arranged around a plurality of planetary gears which can unidirectionally rotate; all the planetary gears can move in a corresponding radial chute on a drive wheel; and stepless transmission is realized by changing the revolution diameter of the planetary gears. An unlocking key is arranged in a one-way clutch of each planetary gear; and when the tooth chain and the planetary gears are meshed and separated, the unlocking key can be driven so that the clutch is maintained in a one-way locking state or unlocking state. The invention breaks through the traditional theory that the stepless transmission is only friction power transmission, solves the problem of carrying out stepless transmission by utilizing a gear, can effectively improve the transfer power of the stepless transmission and has the advantages of large force transmission, high rotating speed, stable running, reliable work, and the like.

Owner:刘爱诗

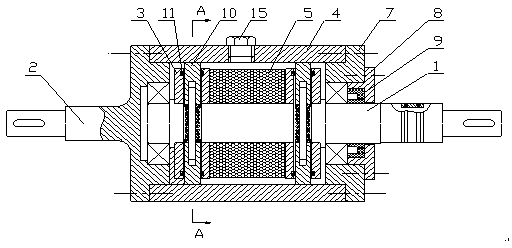

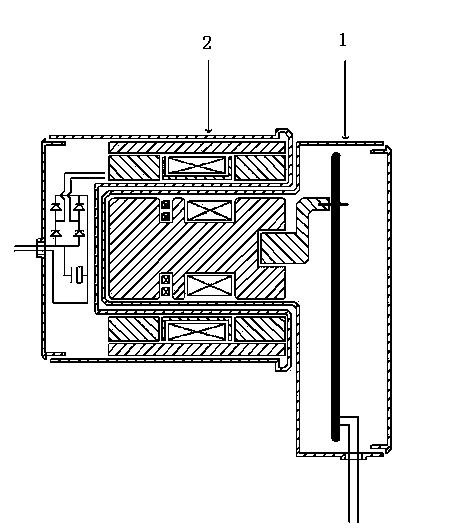

Wedge-shaped extrusion soft start device based on magnetorheological fluid and shape memory alloy

InactiveCN103591234AImprove transfer powerGuaranteed delivery effectFriction gearingsDrive shaftShape-memory alloy

The invention discloses a wedge-shaped extrusion soft start device based on magnetorheological fluid and shape memory alloy. The wedge-shaped extrusion soft start device comprises a driving shaft and a driven shaft. A magnetorheological fluid transmission mechanism is arranged on the driving shaft. The magnetorheological fluid transmission mechanism comprises a driving inner cylinder, a driven outer cylinder and an excitation coil, wherein the driving inner cylinder sleeves the driving shaft and can rotate along the driving shaft, the driven outer cylinder sleeves the driving inner cylinder and can transmit the torque output by the driving inner cylinder to the driven shaft, the excitation coil can generate a magnetic field, a wedge-shaped work gap is formed between the driving inner cylinder and the driven outer cylinder, the wedge-shaped work gap is filled with magnetorheological fluid, and the magnetic field generated by the excitation coil can act on the magnetorheological fluid in the wedge-shaped work gap to enable the driving inner cylinder to drive the driven outer cylinder to rotate through the magnetorheological fluid. The wedge-shaped extrusion soft start device uses the extrusion reinforcing effect of the magnetorheological fluid to improve the transmission power. Meanwhile, the torque is transmitted through assistance of the memory alloy, so that the transmission performance of the soft start device is more reliable.

Owner:CHONGQING UNIV OF TECH

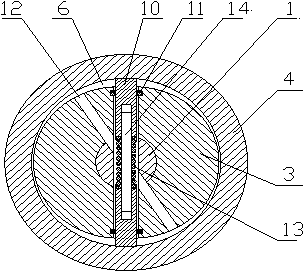

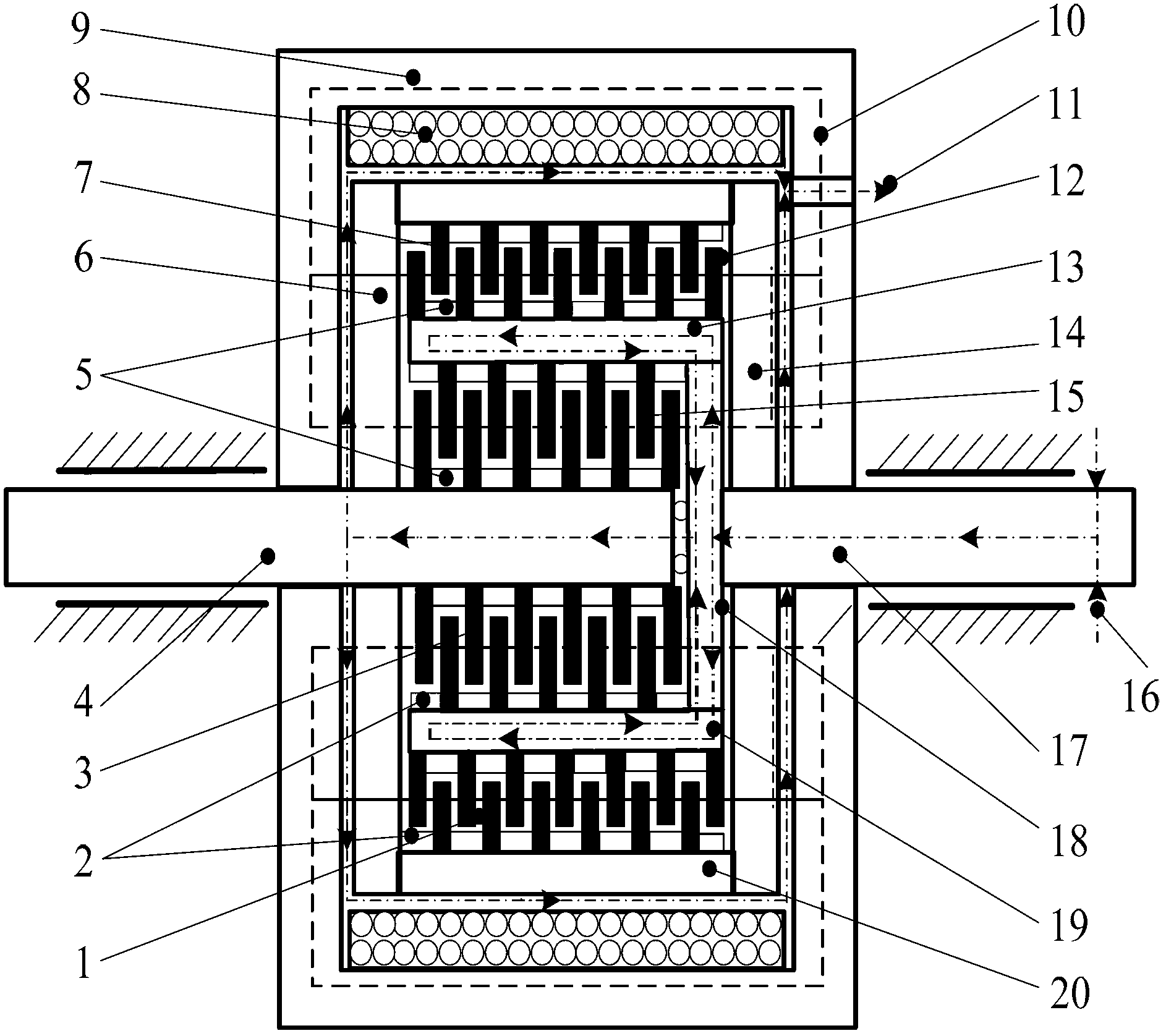

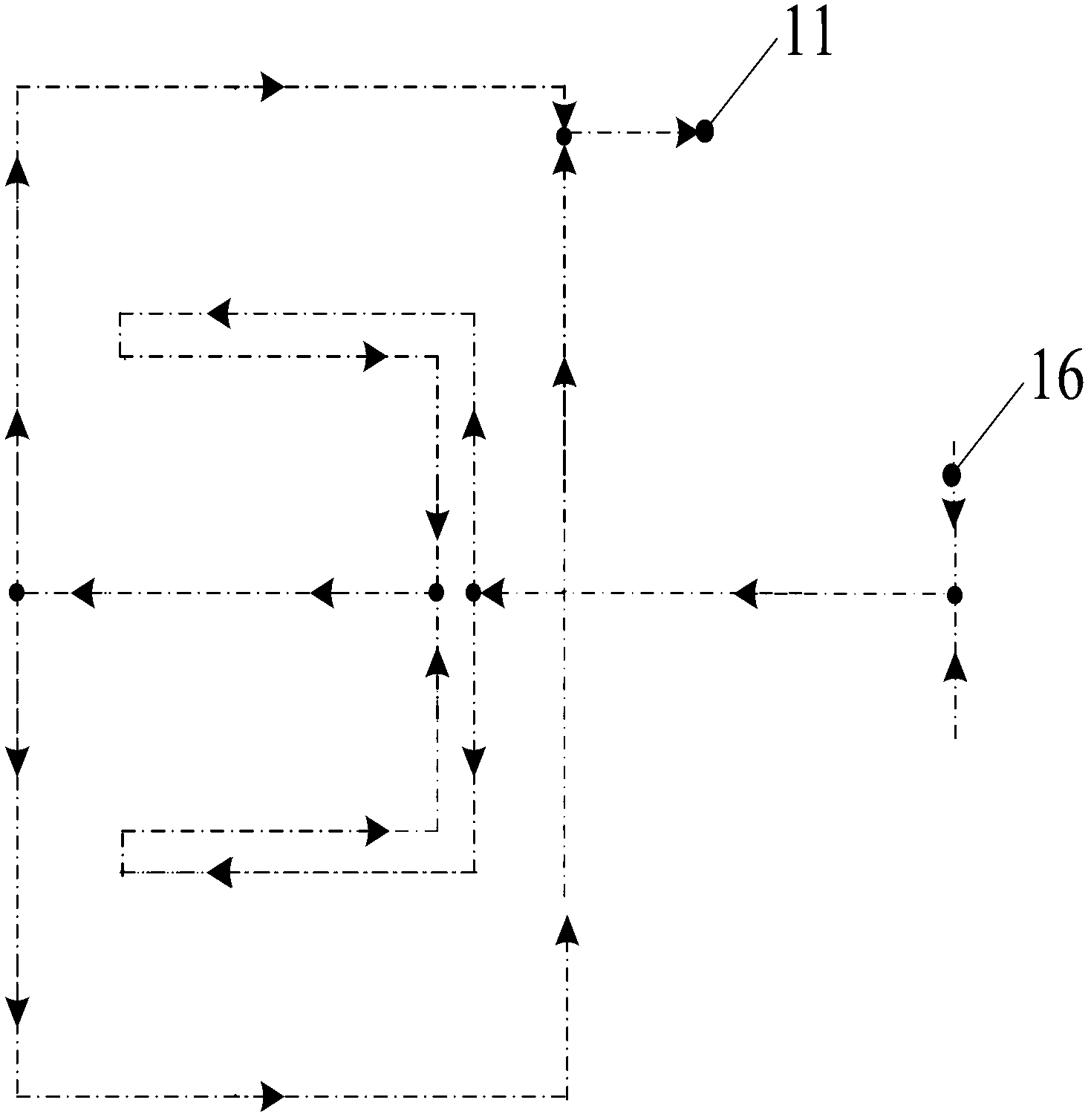

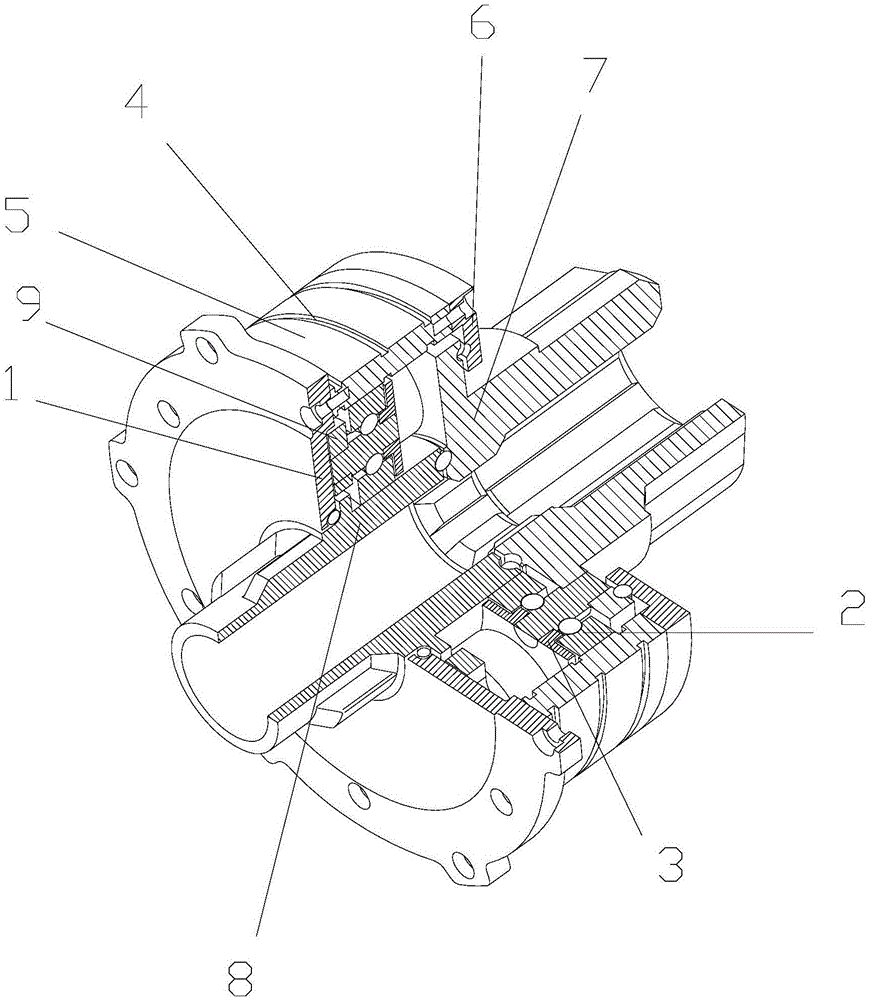

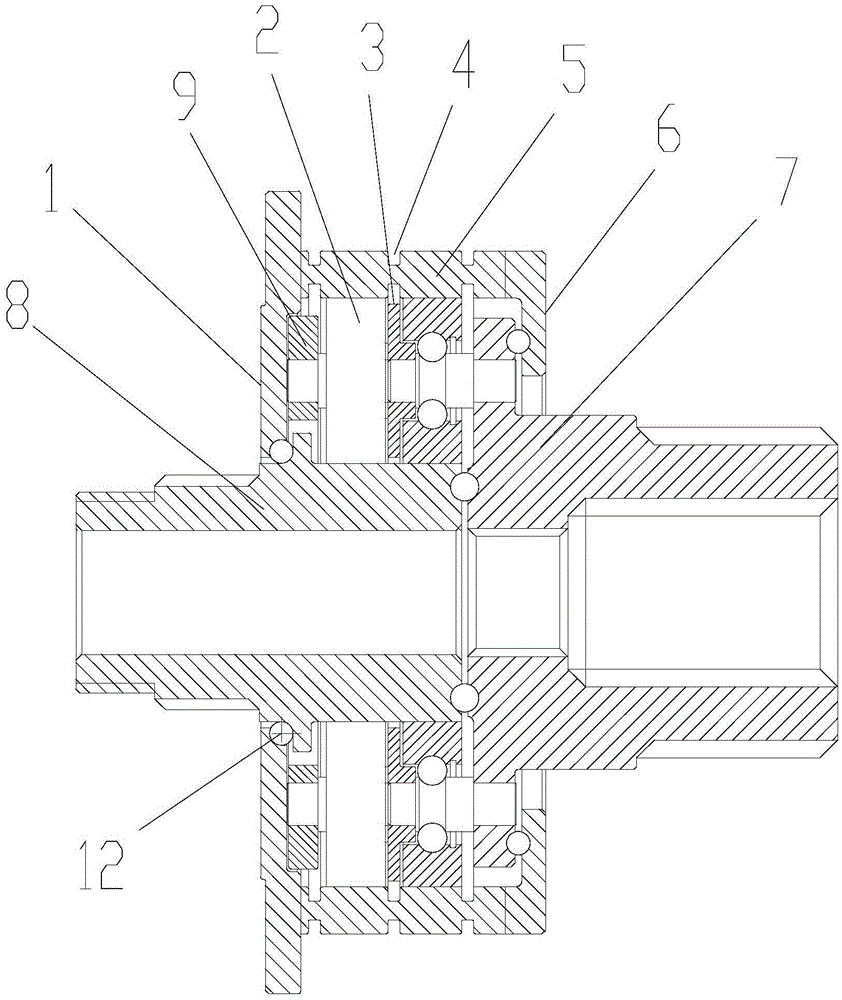

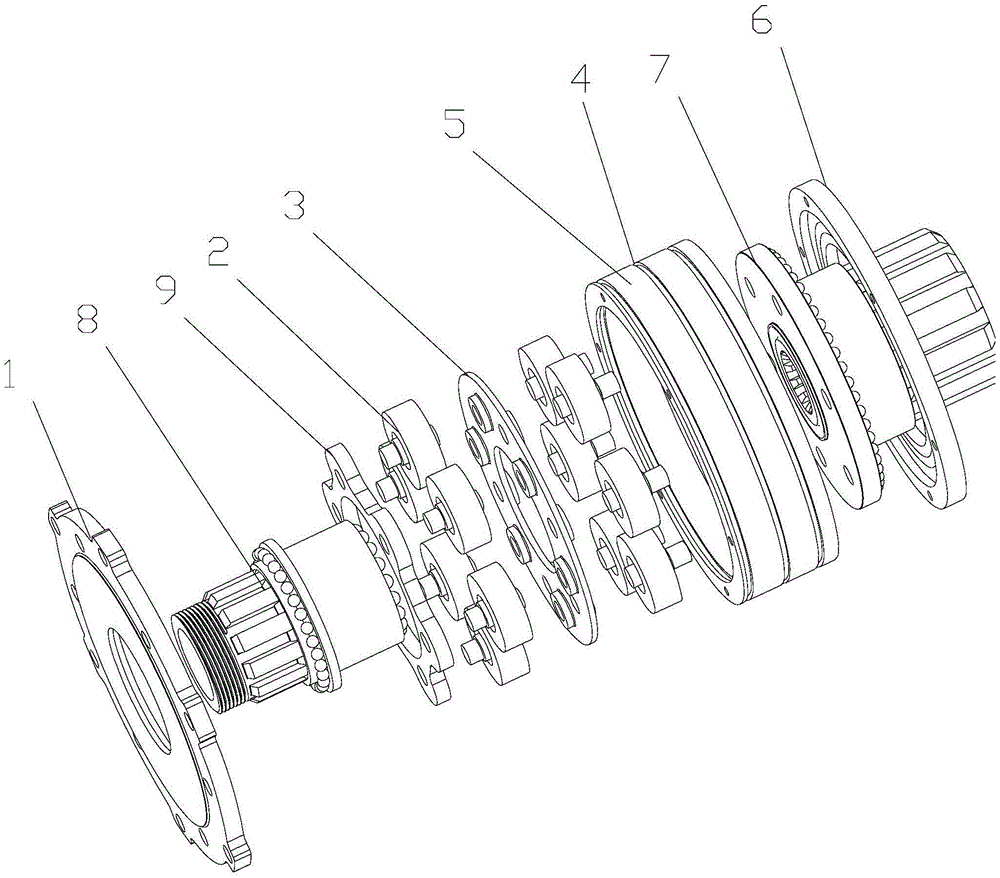

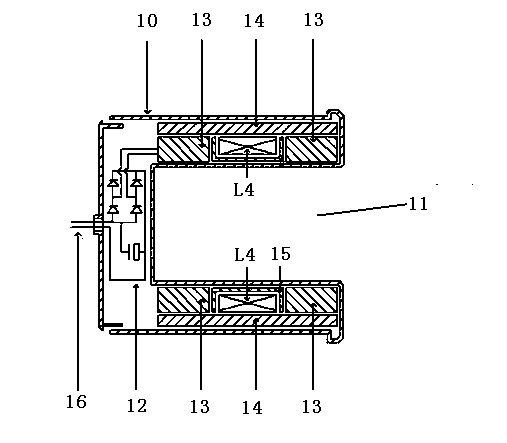

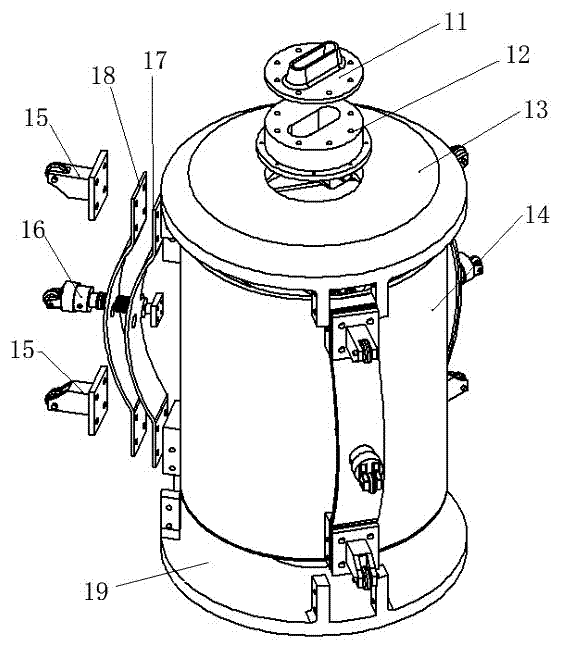

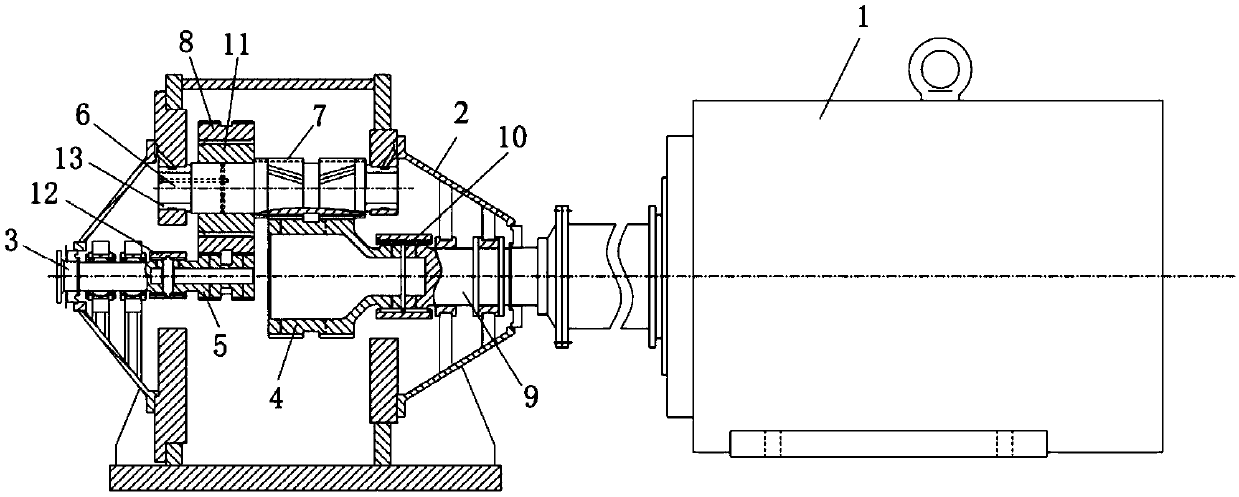

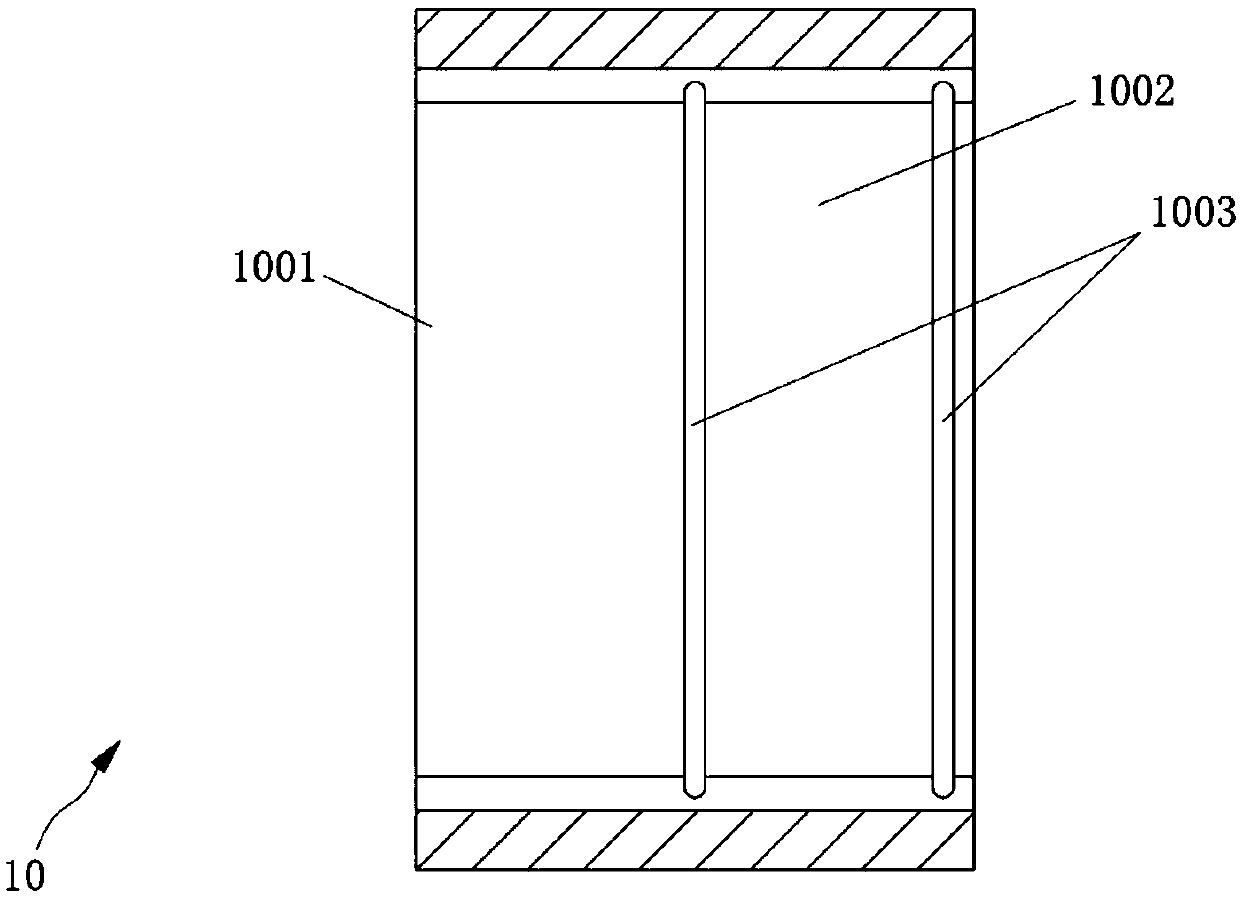

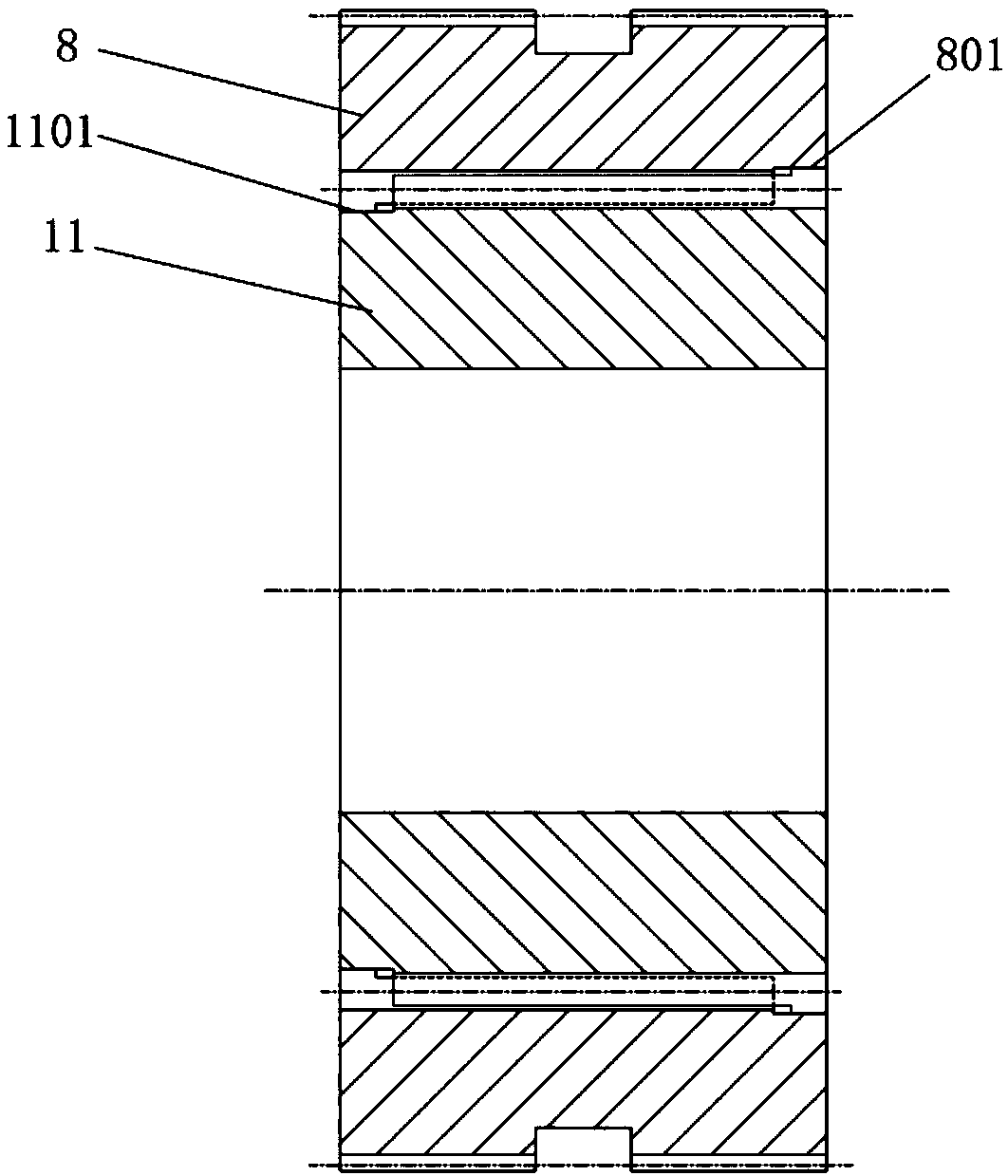

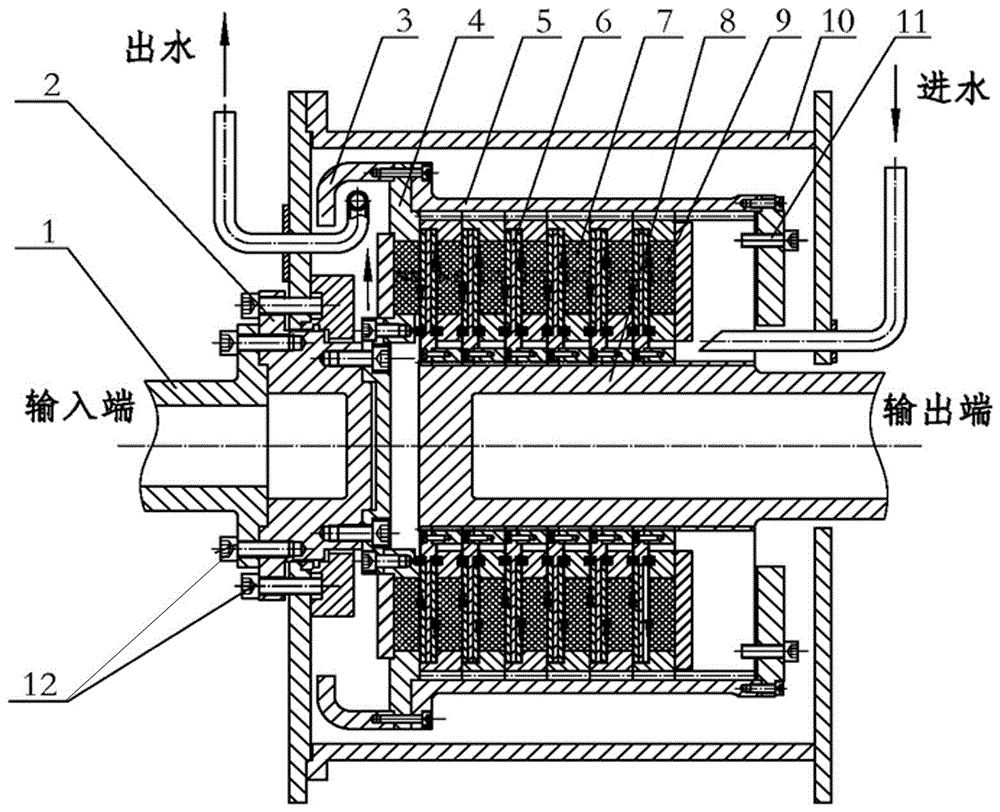

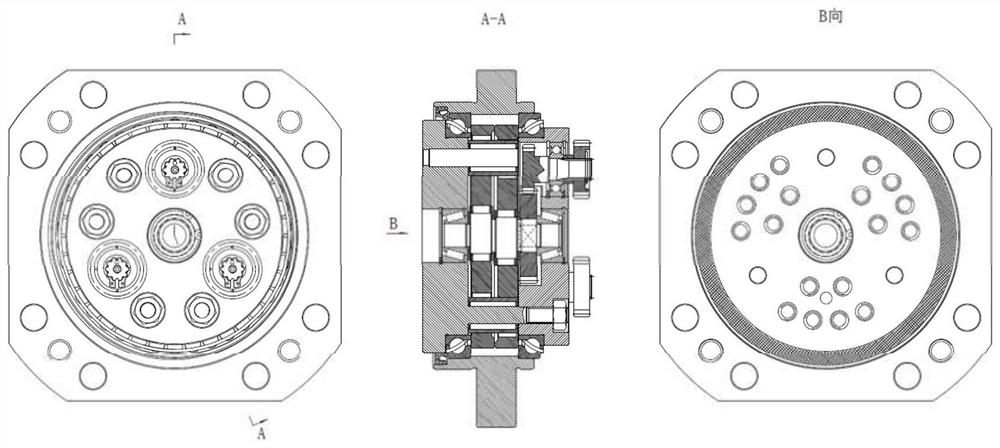

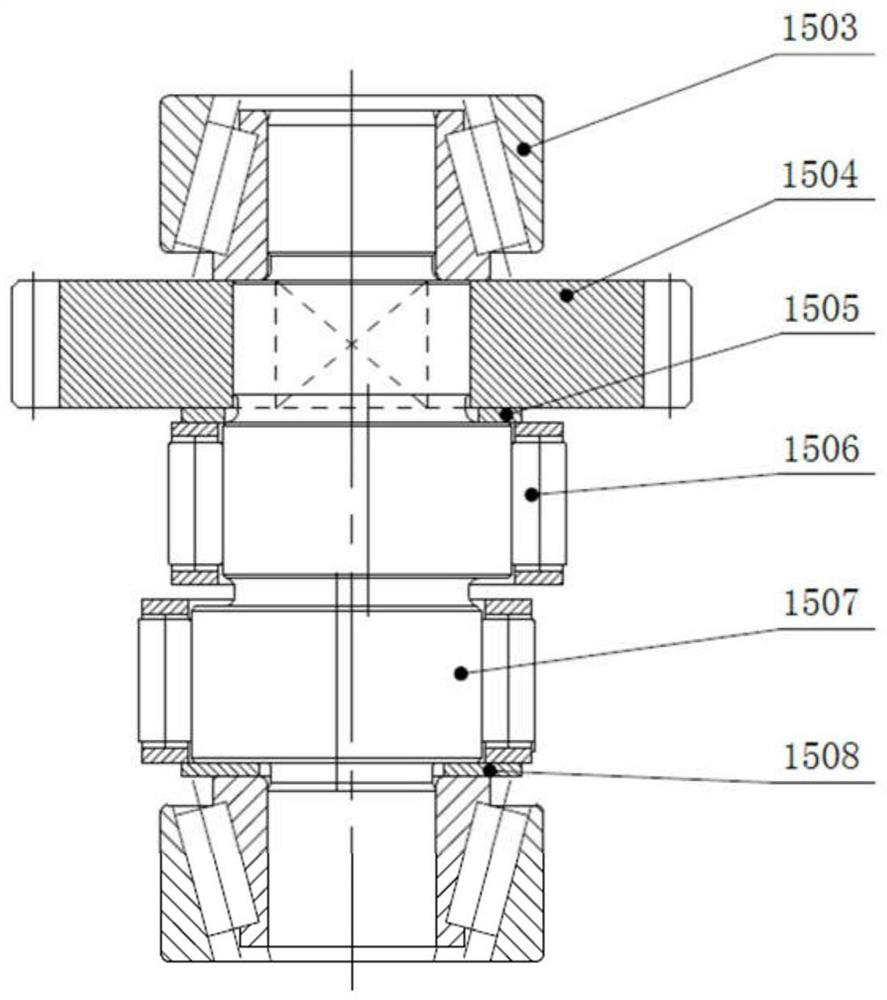

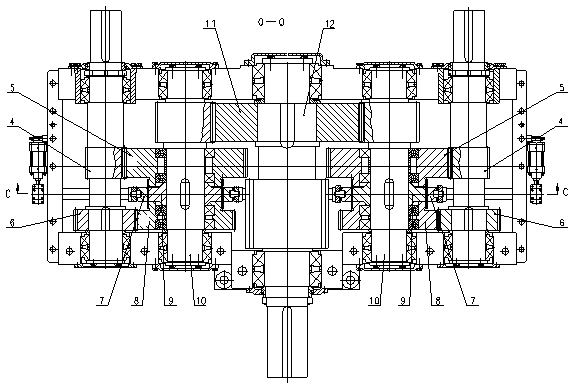

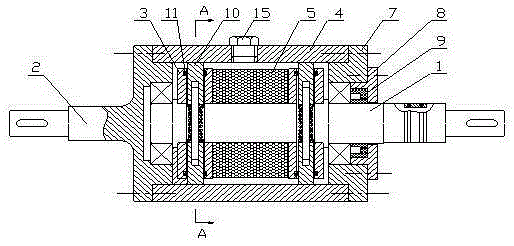

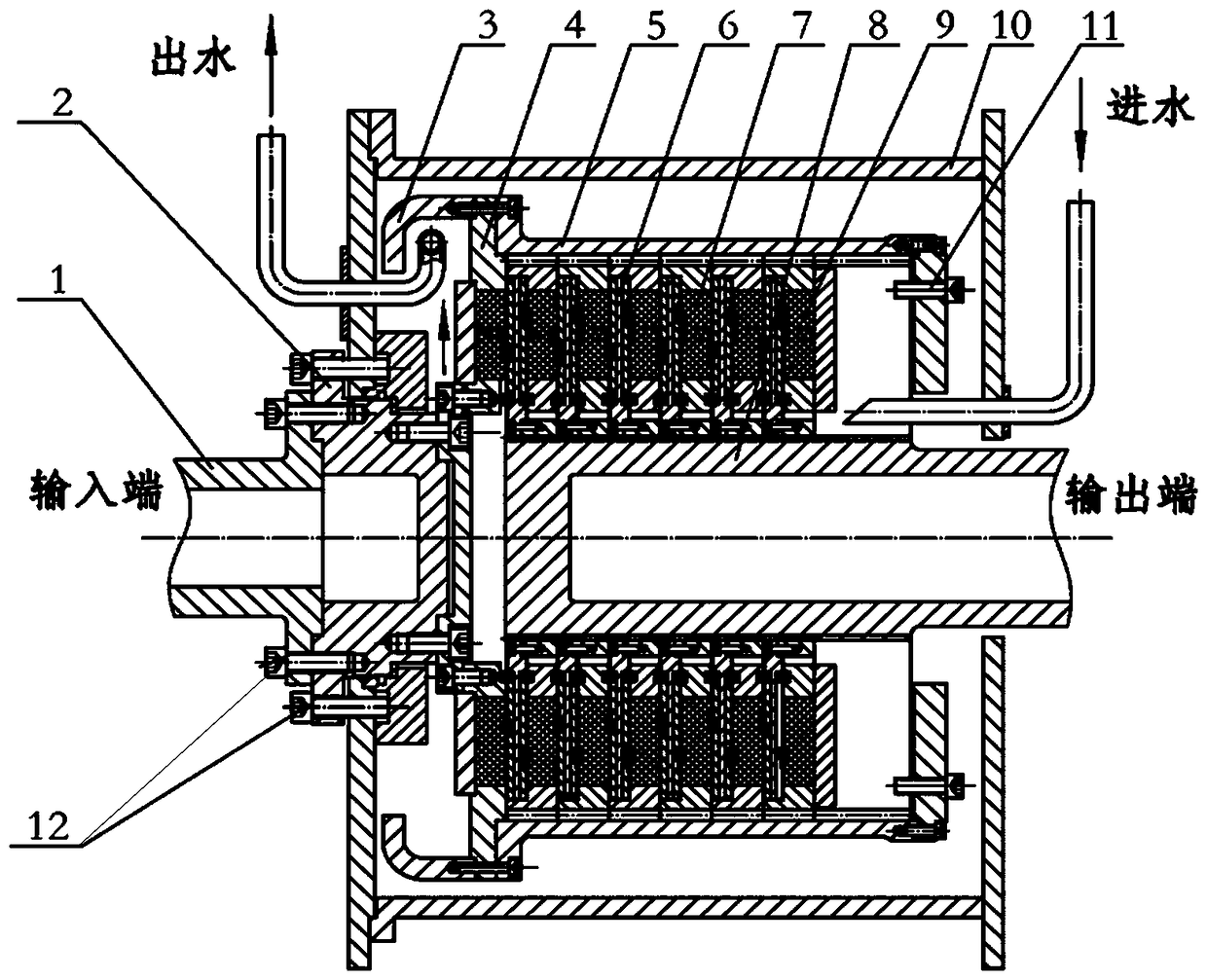

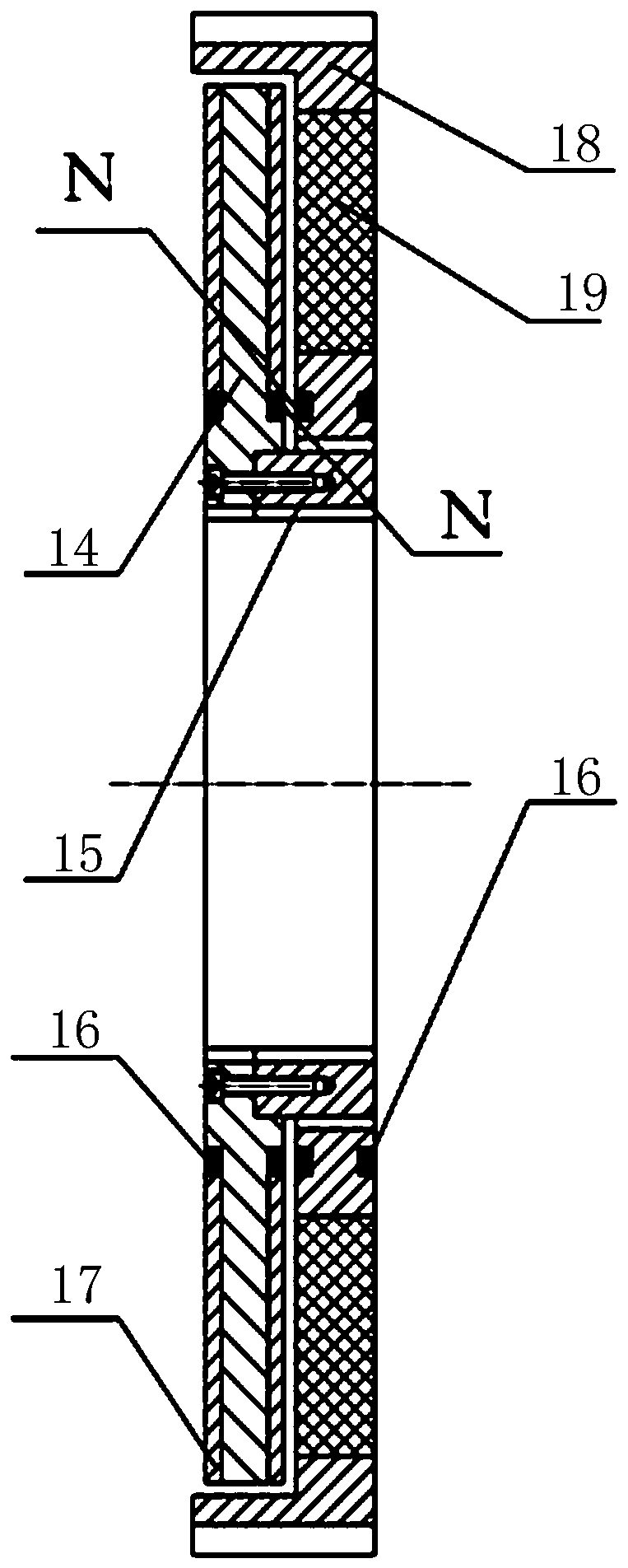

Laminated type high-power magneto-rheological fluid clutch

ActiveCN103161846AEffective dispersionReduce the difficulty of heat dissipationFluid clutchesTransmitted powerDrive shaft

The invention discloses a laminated type high-power magneto-rheological fluid clutch. The laminated type high-power magneto-rheological fluid clutch comprises a primary transmission shaft (4), a left rotary magnetic conductance side board (6), a magnet exciting coil (8), a fixing magnetic conductance outer shell (9), a right rotary magnetic conductance side board (14), a secondary transmission shaft (17), a magnetic conductance board (18), a plurality of layer-adjustable inner layer primary friction plate groups (3), outer layer primary friction plate groups (7), outer layer secondary friction plate groups (12) and inner layer secondary friction plate groups (15), inner layer small magnetic isolation ring groups (2), outer layer small magnetic isolation ring groups (5), an inner layer large magnetic isolation ring (13) and an outer layer large magnetic isolation ring (20). Compared with the prior art, the laminated type high-power magneto-rheological fluid clutch adopts a plurality of friction plate groups for transmission, effectively disperses a heat source, reduces the heat dissipation difficulty, utilizes cooling water for cooling, and obviously improves the transmission power and the heat dissipation effect. When the transmitted power is insufficient, a mode of increasing the layers of the friction plate groups can be adopted, and controllable operation of the transmitted power is easy to achieve.

Owner:XUZHOU WUYANG TECH

Multi-line planetary traction and transmission type speed reducing bearing

ActiveCN105570410AReduce in quantityThe support runs smoothlyRolling contact bearingsGearing detailsPositive pressureReduction drive

The invention discloses a multi-line planetary traction and transmission type speed reducing bearing. An inner ring, an outer ring and rolling bodies of the speed reducing bearing form a planetary traction and transmission gear train jointly and serve as a sun gear, an outer ring and a planetary gear of the planetary traction and transmission gear train correspondingly. According to the planetary traction and transmission type speed reducing bearing, radial supporting of a shaft is achieved by means of the positive pressure between the contact surfaces of the inner ring, the rolling bodies and the outer ring, and movement and power are transmitted by means of the friction force between the contact surfaces of the inner ring, the rolling bodies and the outer ring. The speed reducing bearing integrates the speed reducing function and the bearing function, and at least two lines of rolling bodies are arranged in the axial direction. An intermediate planetary carrier is arranged between every two adjacent lines of rolling bodies, wherein wheel shafts of the two adjacent lines of rolling bodies are connected through the intermediate planetary carrier. The rolling bodies in every two adjacent lines are evenly arranged in a staggered mode in the circumferential direction. According to the speed reducing bearing, the multiple lines of rolling bodies rotate, so that the contact between the rolling bodies, the inner ring and the outer ring is uniform in the circumferential direction and the axial direction, an inner ring shaft can be well supported, and the contact stress of the rolling bodies in the working process can be reduced; meanwhile, the torsional rigidity of a shaft system of the rolling bodies is high so that the torsional deviation of the shaft system of the rolling bodies can be effectively reduced in the transmission process, the situation that a speed reducer is disturbed or gets stuck during the transmission work can be effectively avoided, and the transmission quality and efficiency are improved.

Owner:CHONGQING UNIV

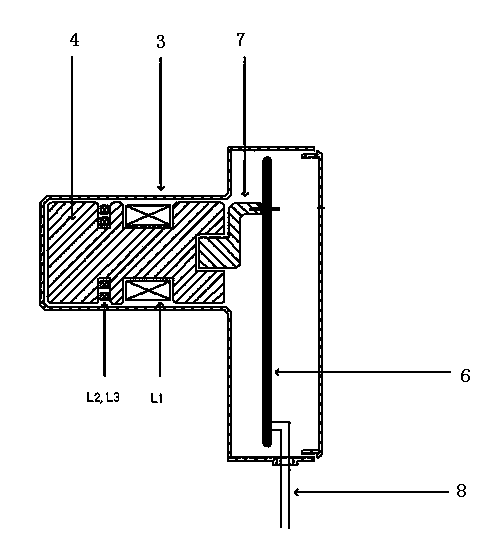

Electro-magnetic inductive plug and socket combination

InactiveCN103972736AAffects the transmitted powerAffect transfer efficiencyBatteries circuit arrangementsTransformersMechanical engineeringElectromagnetic induction

An electromagnetic induction plug and socket comprise a plug (1) and a socket (2). The plug comprises a plug housing (3), the plug housing is provided with a central shaft magnetic core (4), and a plug coil (L1) is wound around the central shaft magnetic core. The socket comprises a socket housing, an annular coil (L4) and an annular magnetic core coordinating with the annular coil are provided in the socket housing, and after the plug is inserted in the socket, the annular coil is sleeved on the plug coil. Mutual induction of primary and secondary coils formed by the plug coil and the socket coil occurs on a same magnetic axis, which is irrelevant to the magnetic flux, magnetic permeability, and the like of an iron core, and the effect of a magnetic loop, formed by the iron core, on the primary coil only decides the amount of induction of the primary coil, as long as the driving frequency or pulse width time of the magnetic loop matches with that of the primary coil; therefore, the iron core magnetic loop in the plug and socket does not affect the transmission power and efficiency due to the existence of iron core gaps. The electromagnetic induction plug and socket have advantages of strong electromagnetic coupling induction capability and high transmission efficiency.

Owner:SHANGHAI KOULIN SEMICON LIGHTING

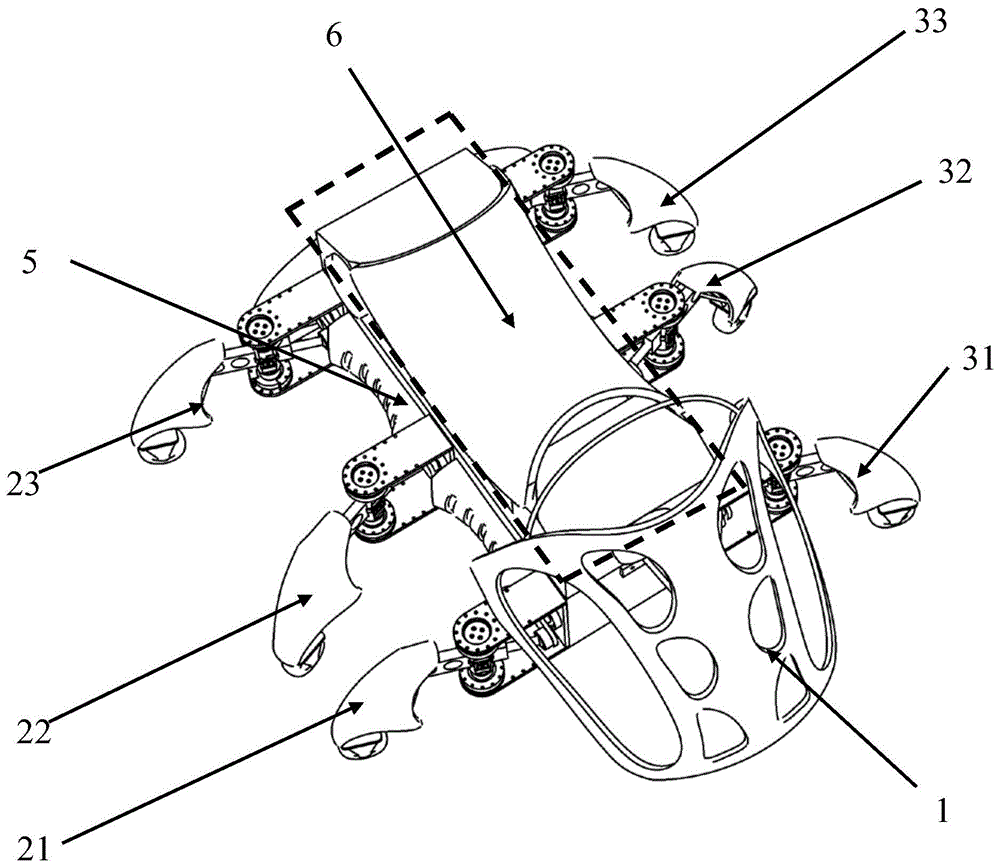

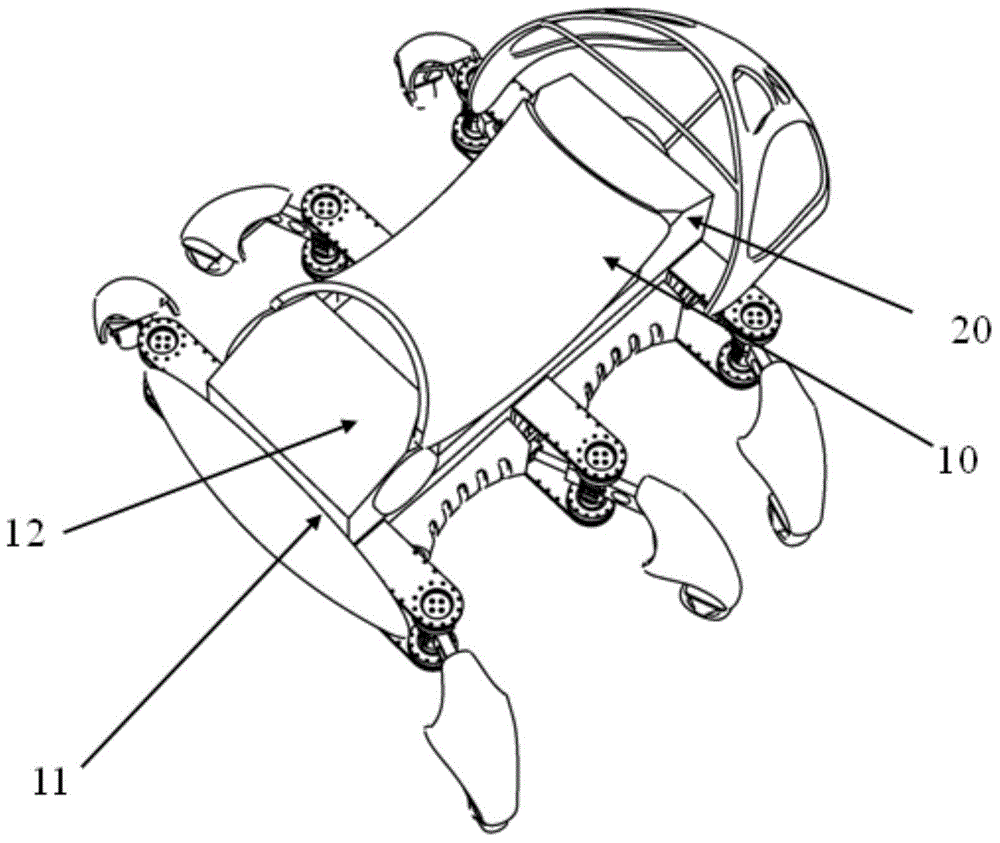

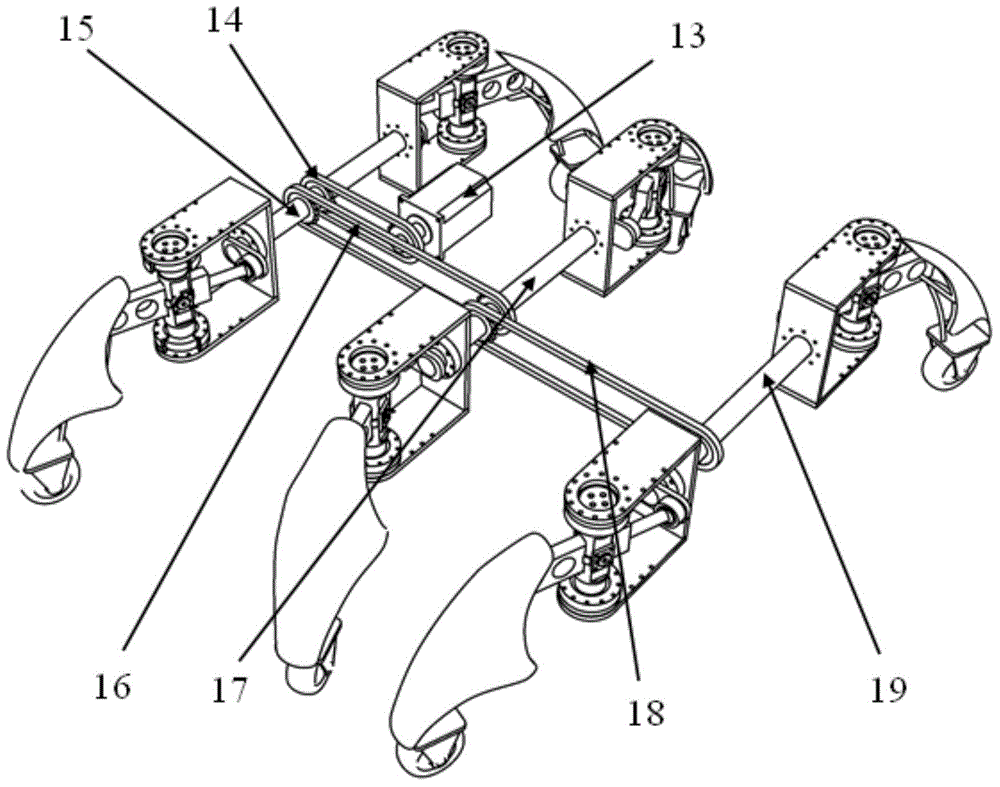

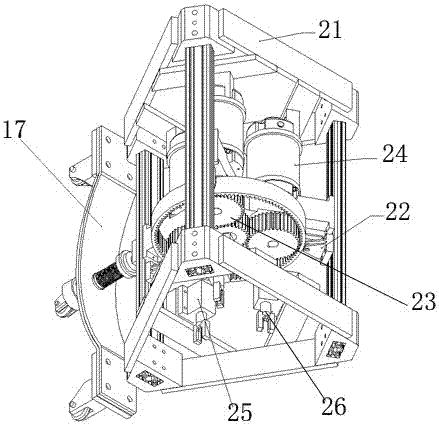

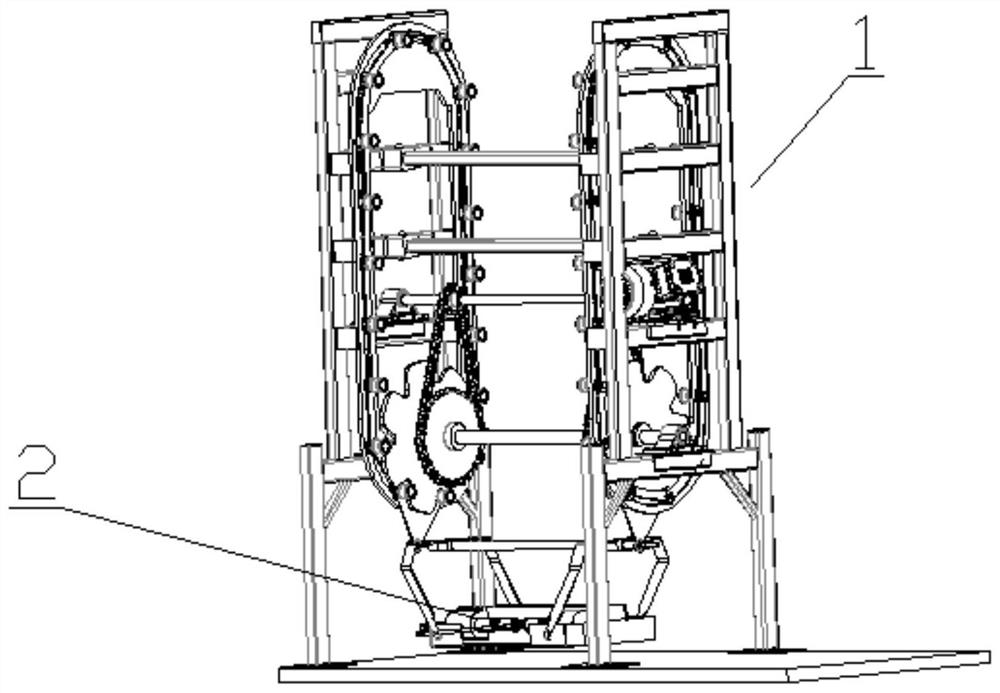

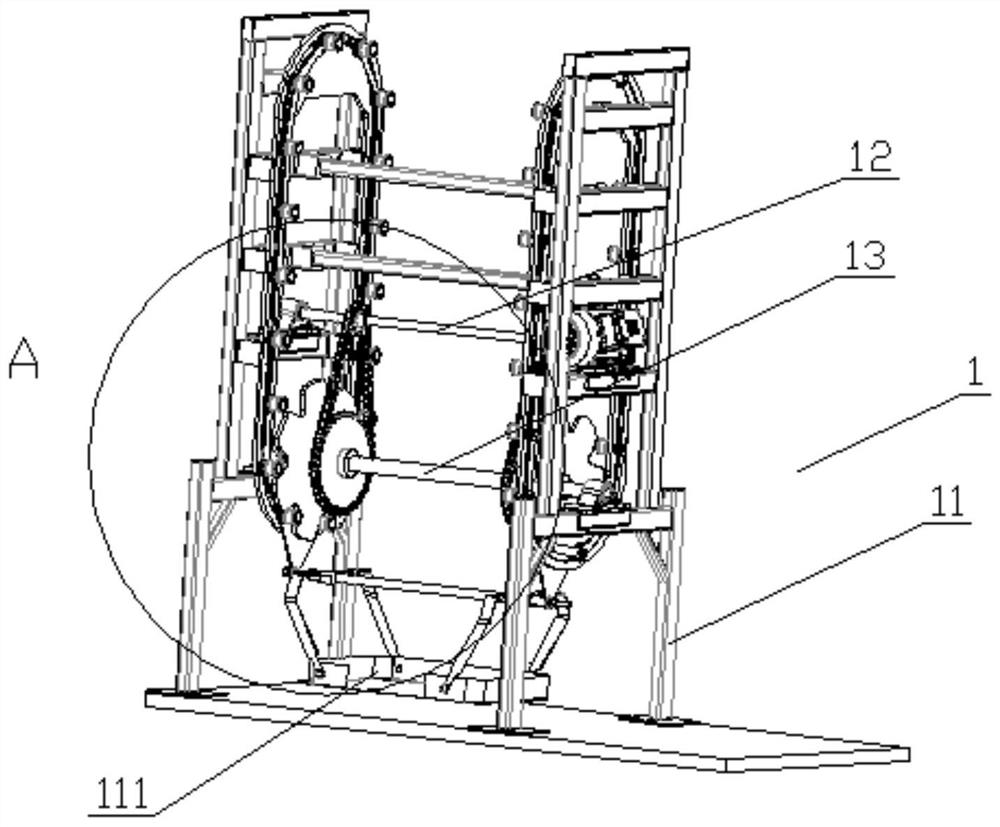

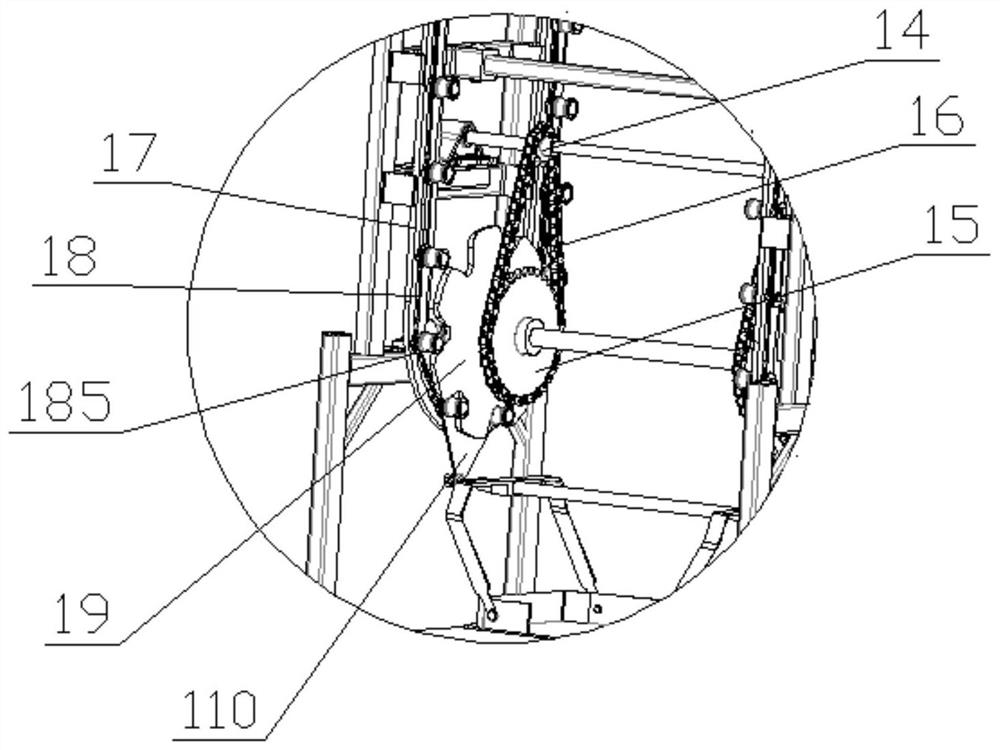

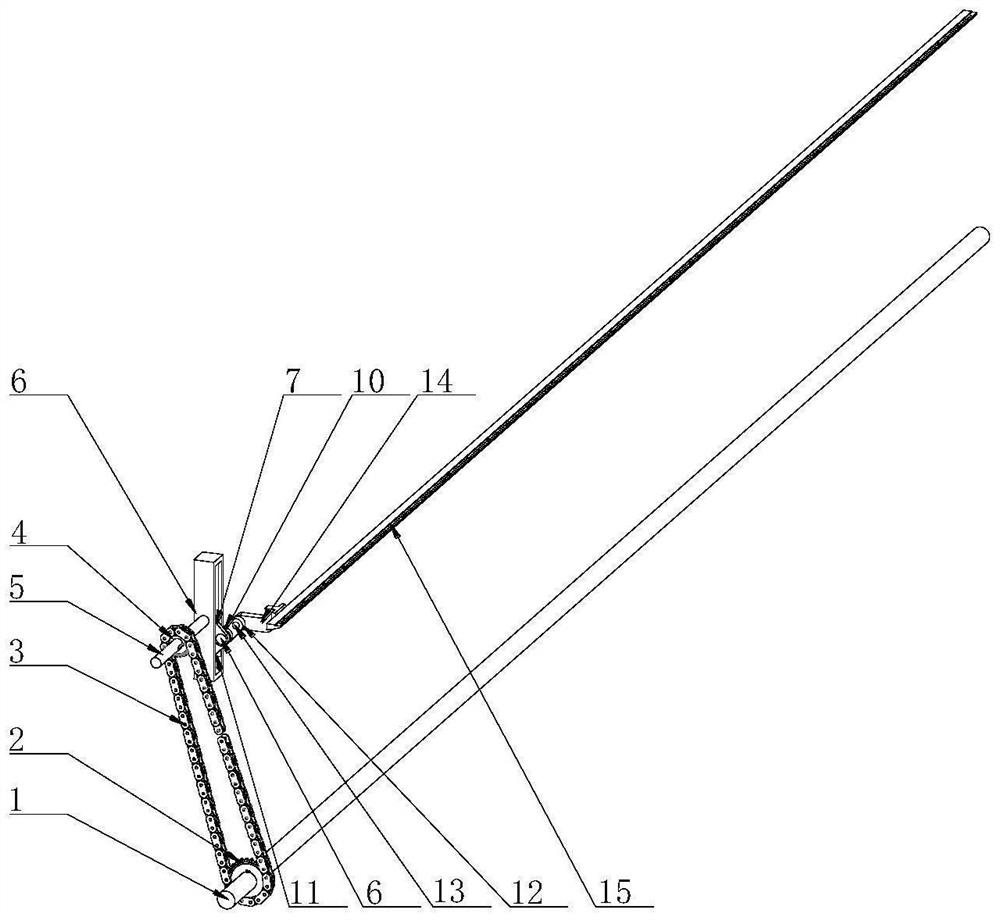

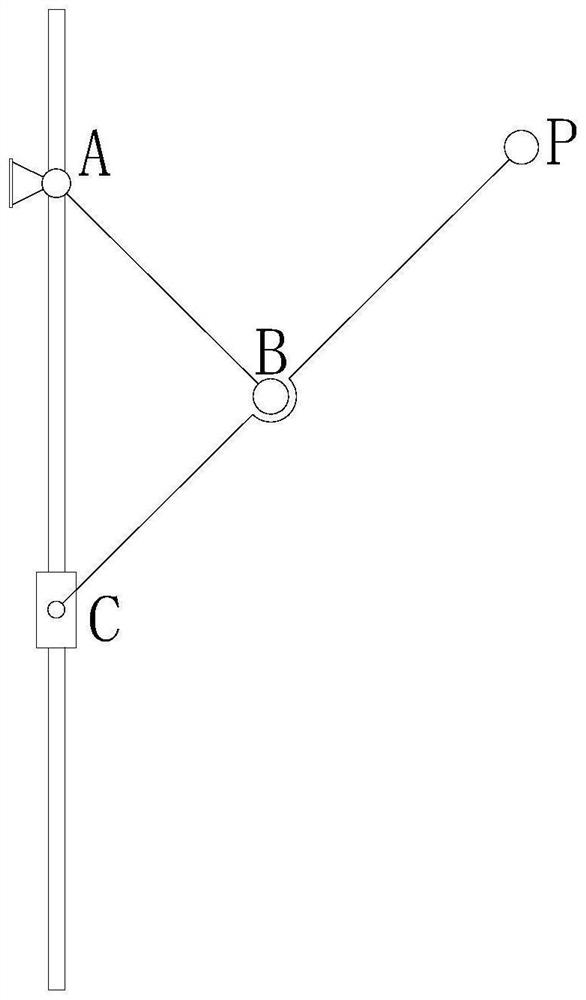

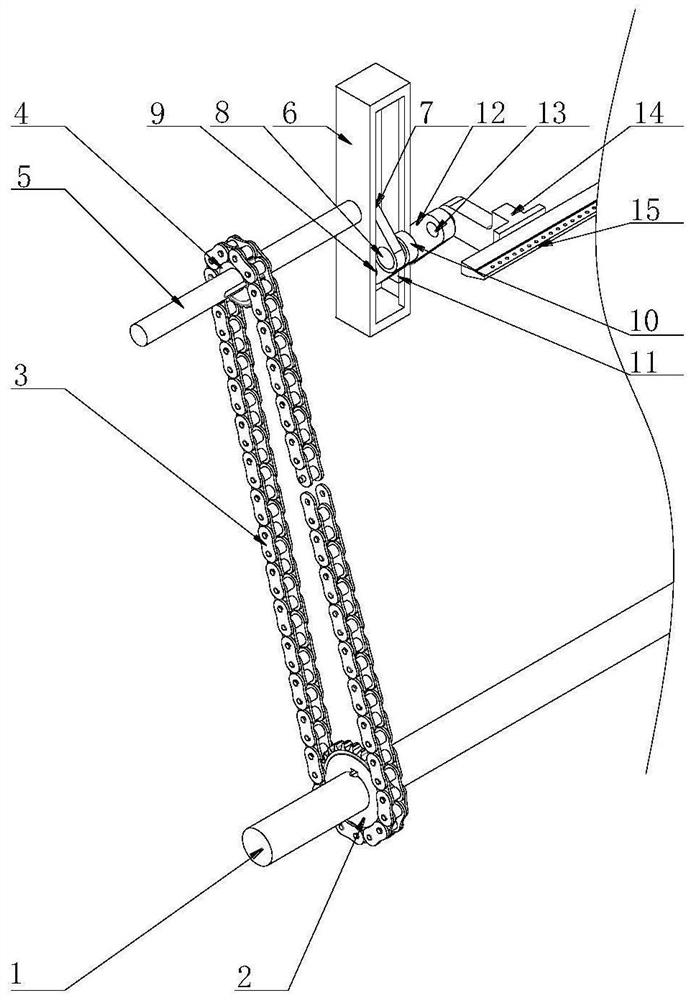

Hexapod robot

The invention discloses a hexapod robot. The robot comprises a head part, a body, a driving device, a transmission system and six mechanical legs. The hexapod robot is characterized in that the six mechanical legs are reversely and symmetrically mounted on both sides of the long edge of the body, and adopt the completely same structures; the driving device and the transmission system are arrayed at the inner part of the body; the driving device performs driving through a servo motor, and the transmission system performs transmission through sprocket chains; three output rods are also arranged at the inner part of the body, and the two mechanical legs are reversely and symmetrically mounted on both sides of each output rod; the six mechanical legs are divided into three groups, and the three groups of output rods are connected in a transmission manner by adopting the sprocket chains; the servo motor of the driving device designed at the inner part of the body simultaneously drives the six mechanical legs to move.

Owner:SHAANXI JIULI ROBOT MFG

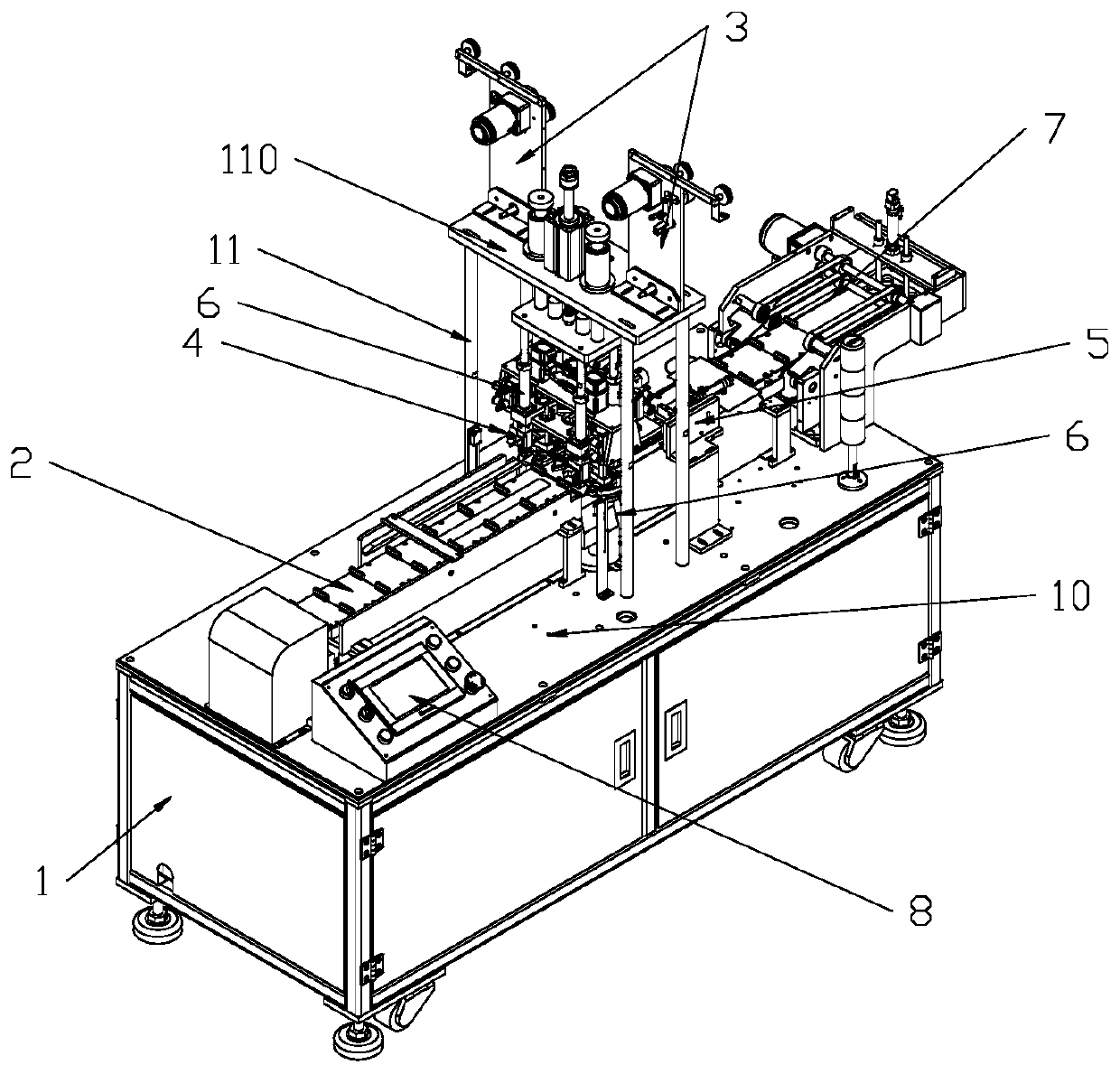

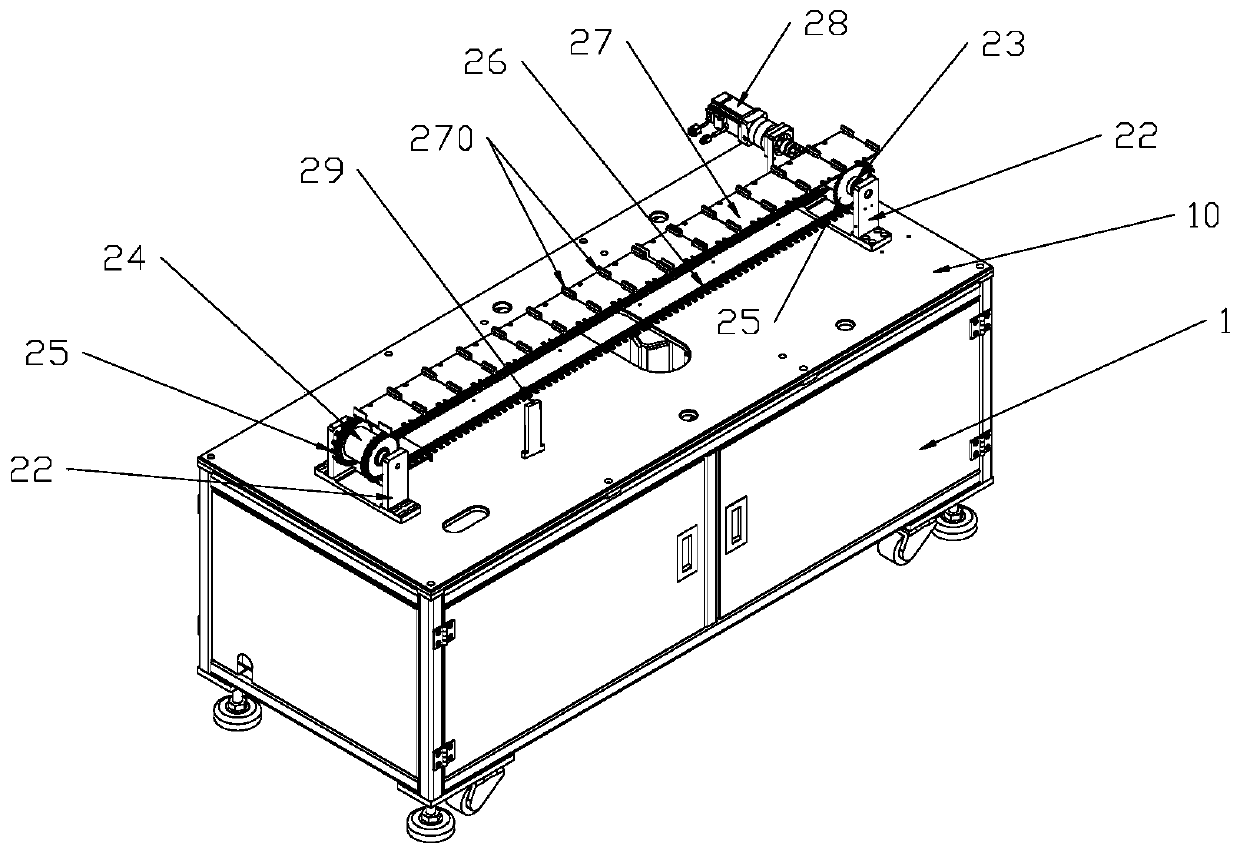

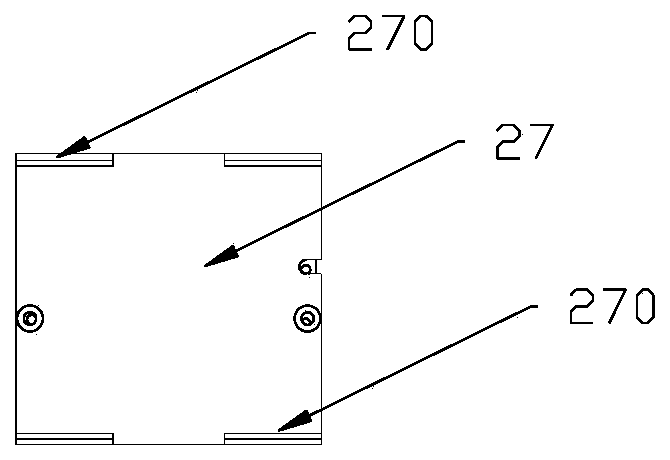

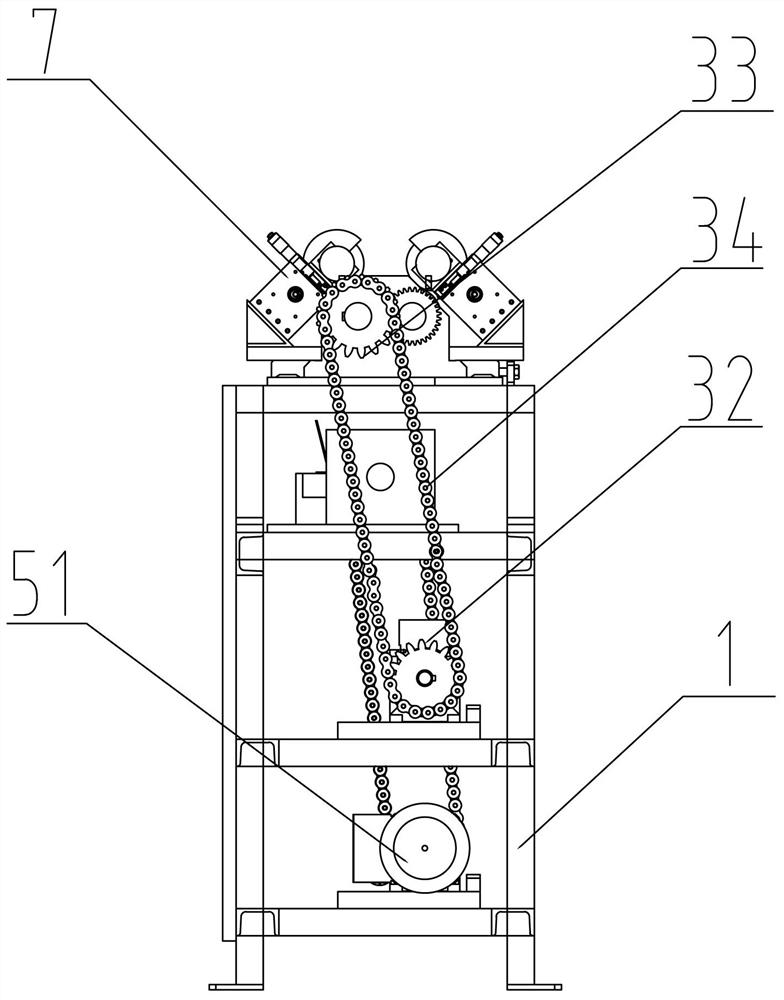

Automatic welding machine for ear straps of face mask

PendingCN111590904AImprove efficiencyImprove pass rateDomestic articlesProtective garmentWinding machinePalletizer

The invention discloses an automatic welding machine for ear straps of a face mask. The automatic welding machine for the ear straps of the face mask comprises a rack. An equipment platform is arranged on the rack, a mask conveying mechanism, a thread feeding mechanism, a thread winding mechanism, a thread shearing mechanism, a welding mechanism, a stacking mechanism and a controller are arrangedon the equipment platform, and the thread feeding mechanism, the thread winding mechanism, the thread shearing mechanism and the welding mechanism are arranged above the mask conveying mechanism. Thestacking mechanism is arranged at the output end of the mask conveying mechanism, the mask conveying mechanism comprises two chain wheel supports, a driving double-chain wheel and a driven double-chain wheel, two parallel and tensioned chains are arranged between the driving double-chain wheel and the driven double-chain wheel, and the two chains are both located on the surface of the equipment platform. A plurality of flat plate type mask carriers are transversely and evenly laid on the two chains. The automatic welding machine for the ear straps of the face mask has the beneficial effects that the conveying positioning precision is high, the average transmission ratio is accurate, the transmission is stable, the efficiency is high, the transmission power is high, the overload capacity ishigh, the high-speed performance is excellent, and maintenance and debugging are convenient.

Owner:HUIZHOU HAPPY VAPING TECH LTD

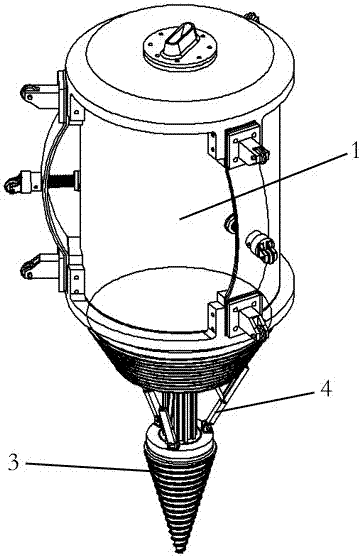

Pipeline dredging device for concrete pump truck

PendingCN107876521AEasy to dredgeEffective dredgingHollow article cleaningBuilding material handlingConcrete pumpDrill

The invention provides a pipeline dredging device for a concrete pump truck, comprising: a device body, a power mechanism, a drilling rig, chains and electric wires; the power structure is arranged inside the device body, and the drilling rig is arranged in the Outside the device body, the power mechanism provides power support for the drilling machine. The technical problem to be solved by the present invention is to provide a pipeline dredging device for concrete pump trucks that can truly and effectively clear pipeline blockages and further improve work efficiency.

Owner:王跃龙

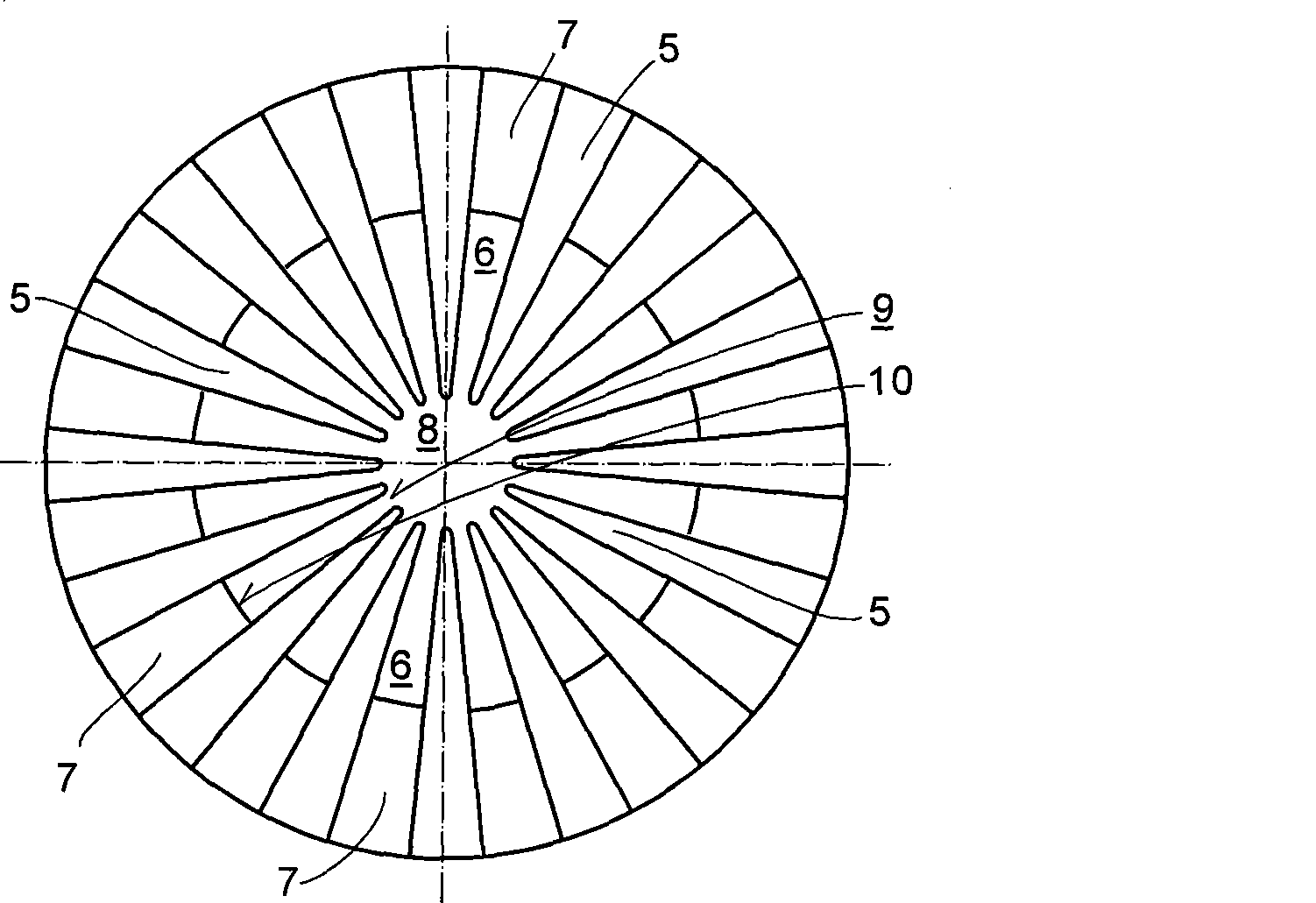

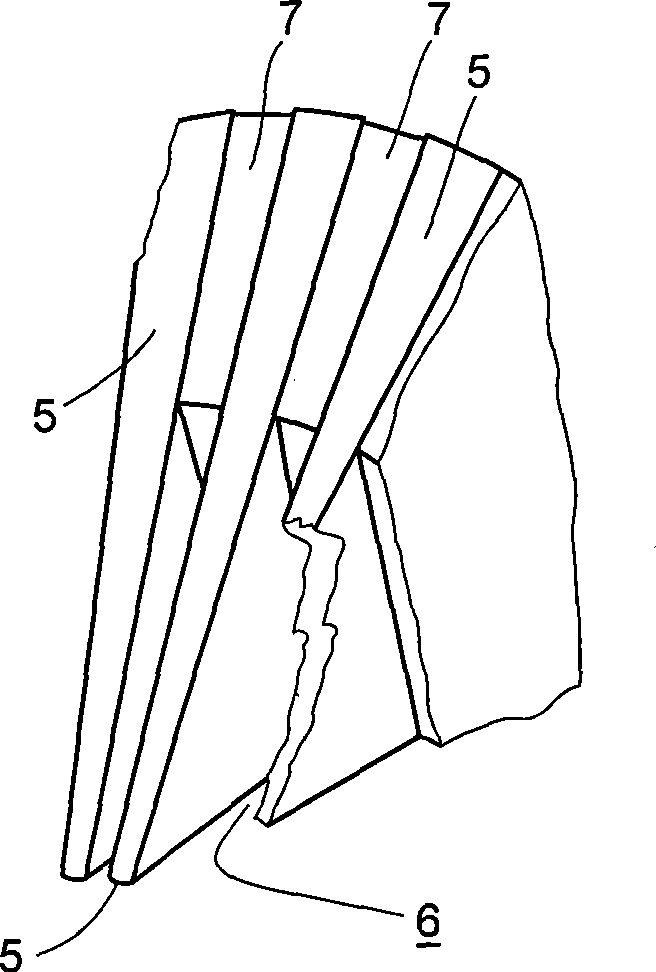

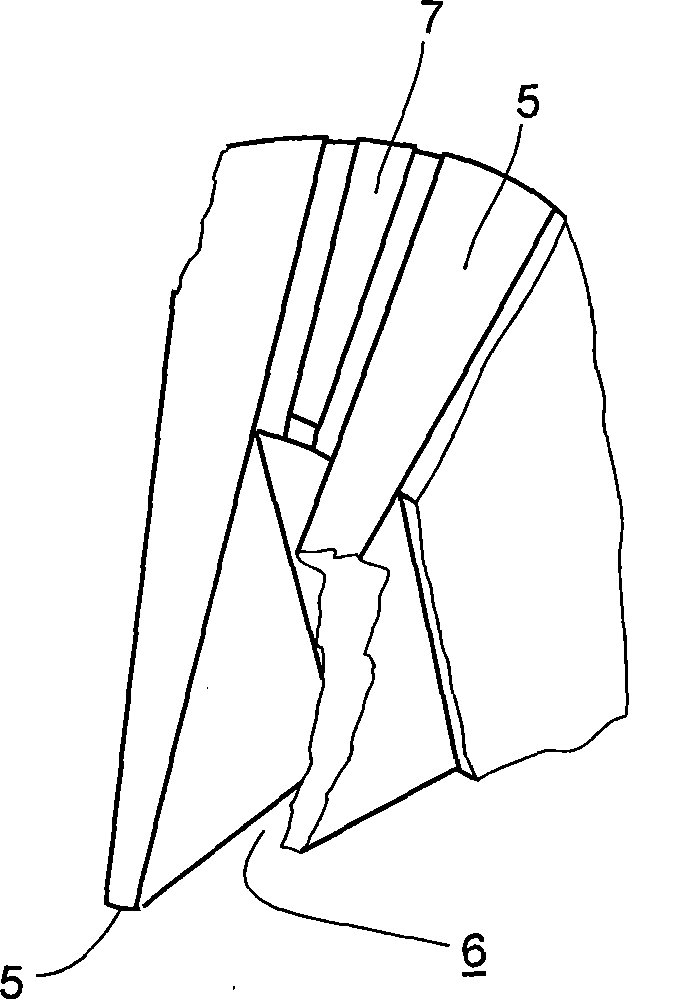

Stepless variable drive of stepless transmission

InactiveCN101457823AIncrease pressureReduce pressure differenceGearingTransmission beltFriction force

The invention discloses a stepless speed change device of continuously variable transmission (CVT), both the driving pulley and the driven pulley of which are formed by inserting movable cone plate and fixed cone plate alternately. Alternately arranged fan-shaped groove (6) and fan-shaped spoke (5) are arranged on each cone plate surface, both cone plates of one pulley can do to-and-fro sliding movement by inserting its fan-shaped spoke (5) into the other fan-shaped groove (6), and driving radius of pulley is altered by changing insertion level. The two alternately inserted cone plates can form a pulley the V-shaped ring groove of which is larger than 45 DEG, the transmission of power is realized by tense friction force for the two pulleys and transmission belts comprised of multilayer steel endless belts, and the transmission belts can bear stretching force that can produce huge friction force, therefore, the transmission powder is great; and if external goop chain and internal laxation layer are applied, the effect will be much better. Meanwhile, the main force applied to the transmission belt by the pulley is outward radial force, and movements are smooth when the driving radius is enlarged. In addition, the friction of idle work does not exist when the transmission belts pass in and out of the pulley, therefore, the service life of the stepless speed change device is long.

Owner:麦锡汕 +1

Intelligent automatic branches pruning device

InactiveCN107926332AImprove pruning efficiencyImprove versatilityCuttersMotor driven pruning sawsAgricultural engineeringPruning

The invention discloses an intelligent automatic branch pruning device, which is composed of a climbing mechanism, a pruning mechanism and a pressing mechanism, and is characterized in that a pruning mechanism is installed on the climbing mechanism, and a pressing mechanism is installed on the climbing mechanism . The advantage is that the intelligent automatic branch pruning device can replace manual branch pruning, which improves the efficiency of branch pruning and reduces the labor intensity of garden workers. Moreover, the device can realize the pruning of tree branches of different thicknesses. Different, the intelligent automatic branch pruning device can automatically adjust the internal spacing to meet the pruning work for trees of different thicknesses, avoiding the difficulty that the same branch pruning device cannot complete the job due to different tree thicknesses, improving the versatility of the branch pruning device, reducing pruning costs.

Owner:李洪龙

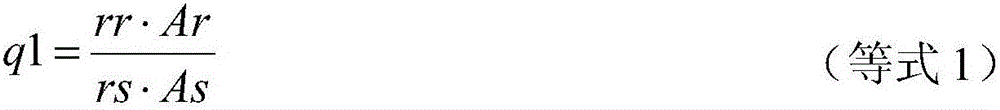

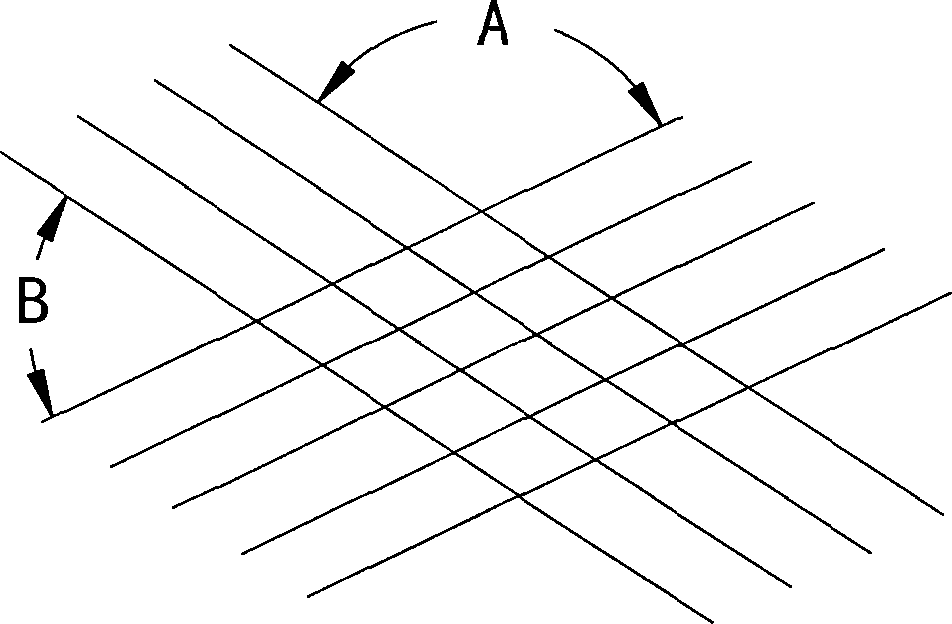

Movable teeth quasi-stepless speed change device

The invention provides a movable teeth quasi-stepless speed change device, comprising a metal band, a driving shaft and a driven shaft, wherein, the driving shaft and the driven shaft are respectivelyinstalled with a fixed cone disc and a corresponding removable cone disc; the cone disc is provided with two to three groups of equant dovetail grooves which are vertical to the rotating direction; the fixed cone disc and the dovetail grooves on the removable cone disc correspond mutually; more than two movable teeth bodies constitute a movable teeth base; the movable teeth body is provided withdovetail blocks and teeth; the dovetail blocks on the movable teeth body are embedded into dovetail grooves; and when the fixed cone disc and the removable cone disc approach or separate, the two to three groups of equant movable teeth bases glide radially in an equal radius, thus changing the working radius of the movable teeth base, achieving the purpose of speed change, changing the friction transmission to gear transmission, and greatly improving the transmission power, the torsion and the mechanical efficiency. The invention also provides a novel structure of mechanical automatic pressurizing and speed adjusting to substitute the common hydraulic pressurizing system.

Owner:郭质刚

Roller-type step-less speed variator containing shear-like lever plate

This invention relates to a chain stepless gear, in which, the input shaft and the output shaft are mounted parallel to a tensional chain screw mandrel, two opposite chain wheel faces form a wedge notch to clamp the chain as a drive chain characterizing that a speed lever is a single lever and long and short scissor-like lever plates, in which, the pivots of which are a same one mounted on the tensional chain screw mandrel and the speed screw mandrel, the active points of the lever plates are installed on two pressure rings, one is sleeved on the chain wheel handle, the other is covered on the pressure cam sleeved on the shaft, two V-shape notches are opened between the cam end face and the end face of the chain wheel handle filled with steel balls, the single lever takes the tensional screw mandrel as the pivot connected with the chain wheels mounted on the shafts, the right and left ends of the speed screw mandrel are screw rods connecting the single lever and the speed screw mandrel.

Owner:上海中纺机通用机械有限公司

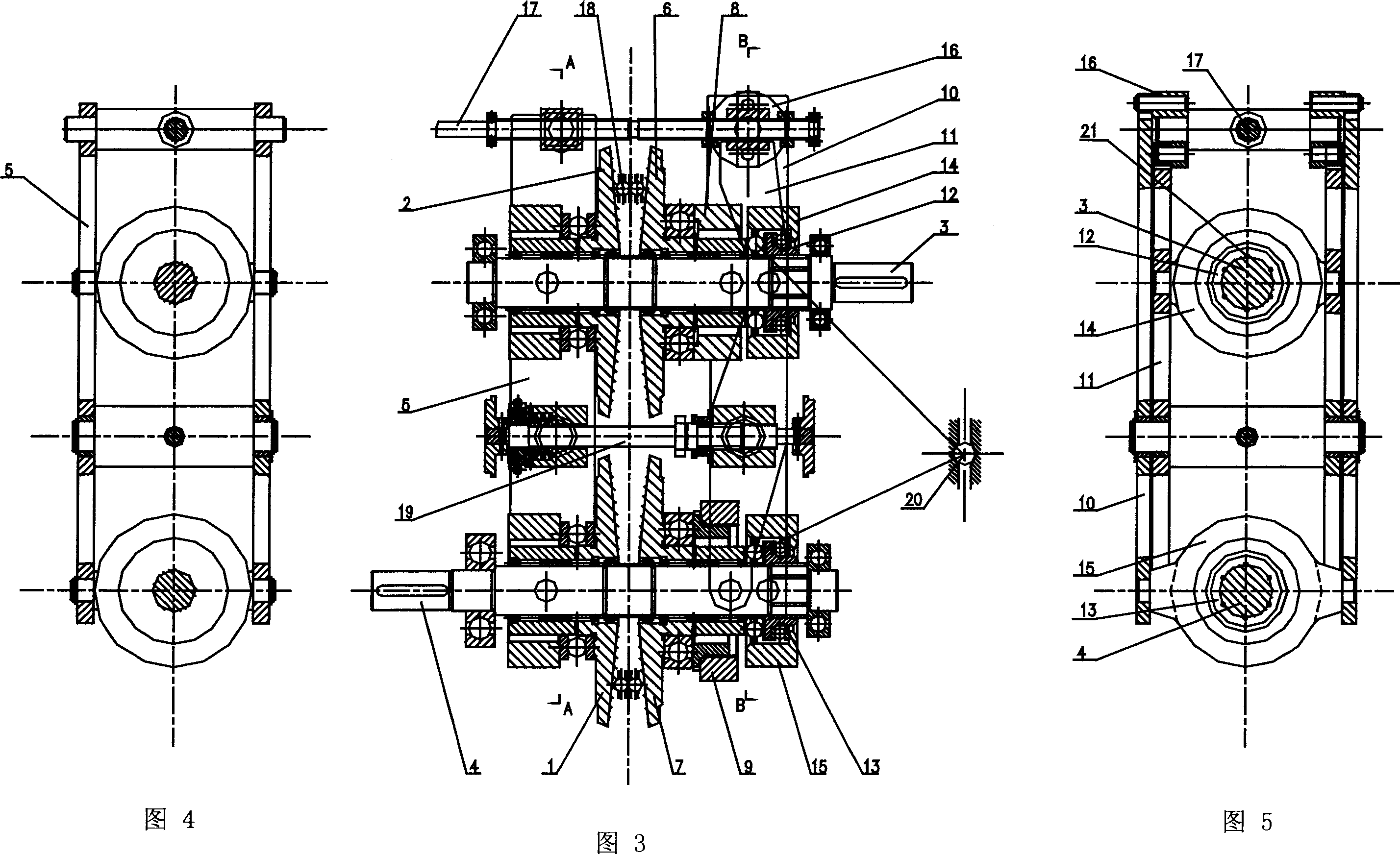

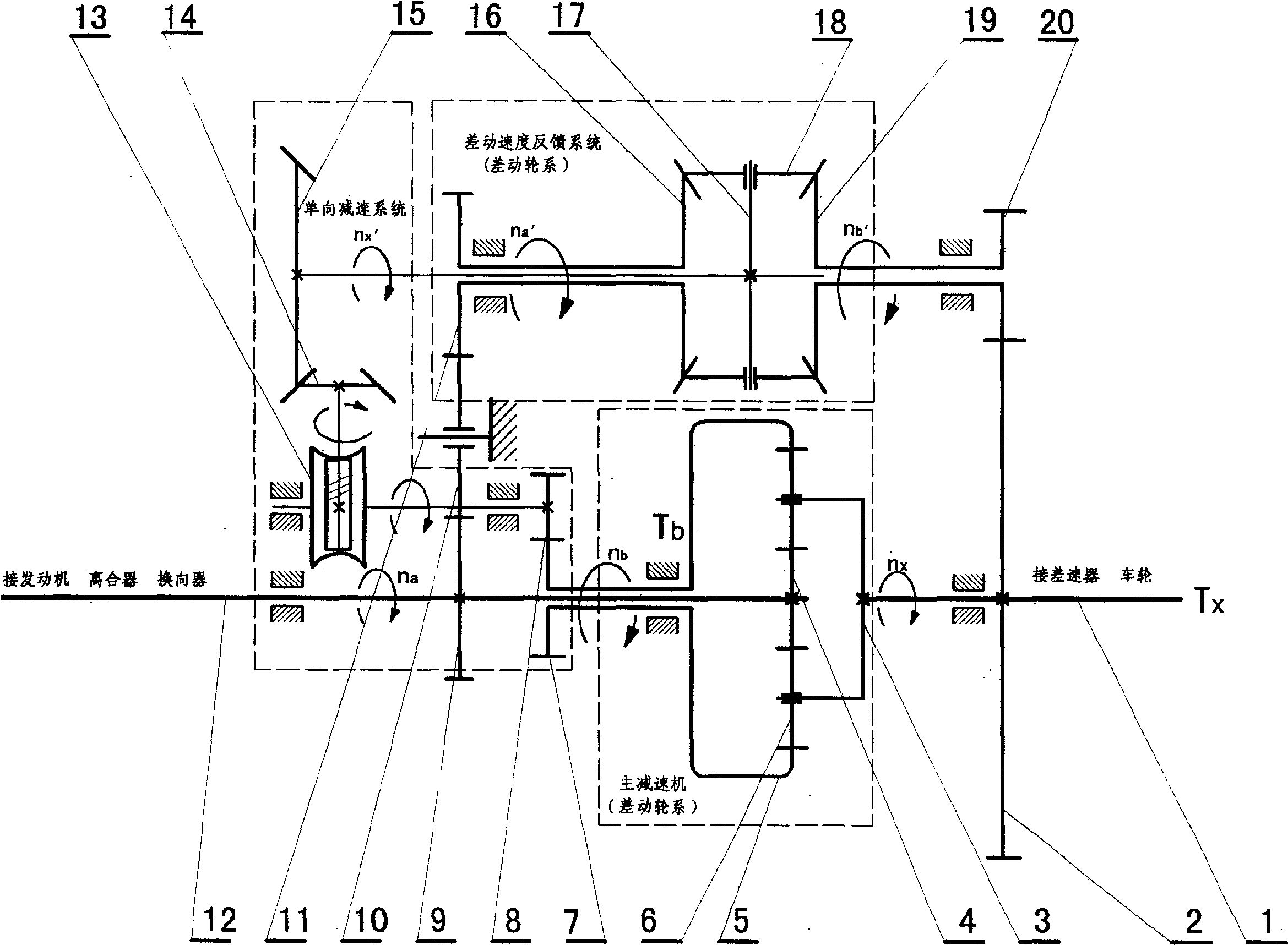

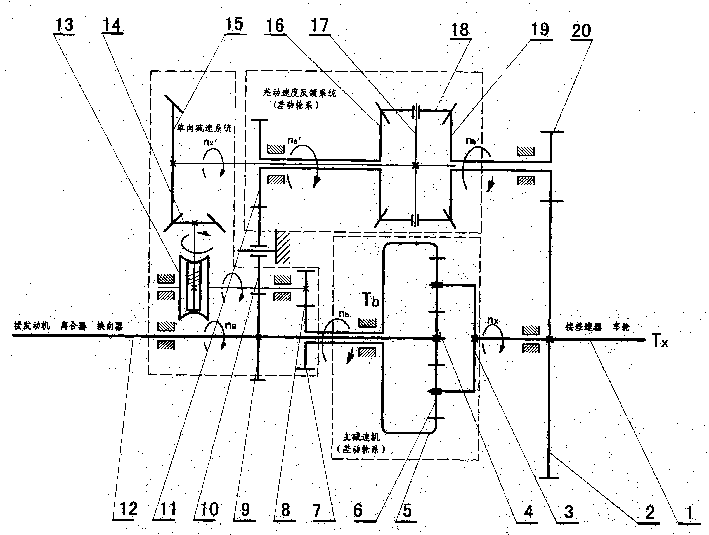

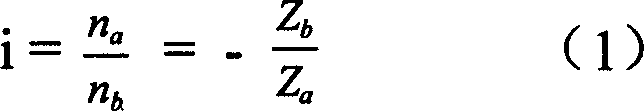

Double differential type planetary stepless automatic variable speed gear for vehicle

InactiveCN1565882AImprove reliabilityImprove transmission efficiencyControl devicesGear driveGear wheel

A double differential planetary stepless automatic speed change device for vehicle in which the main speed reducer is composed of a differential planetary gear train, and the differential speed feedback system is composed of another differential planetary gear train, both of the two parts connect to the one-way deceleration system. According to the invention, when the rotating speed difference between the input shaft and output shaft of the main speed reducer varies continuously, the rotating speed of the planet carrier of the differential speed feedback system varies continuously to control the rotating speed of the ring gear of the main speed reducer to vary continuously, so as to realize the full stepless variation of the transmission ratio of the main speed reducers. Then invention employs gear transmission which can greatly improve the reliability and the transmission efficiency of the stepless automatic speed change device.

Owner:邵培森 +1

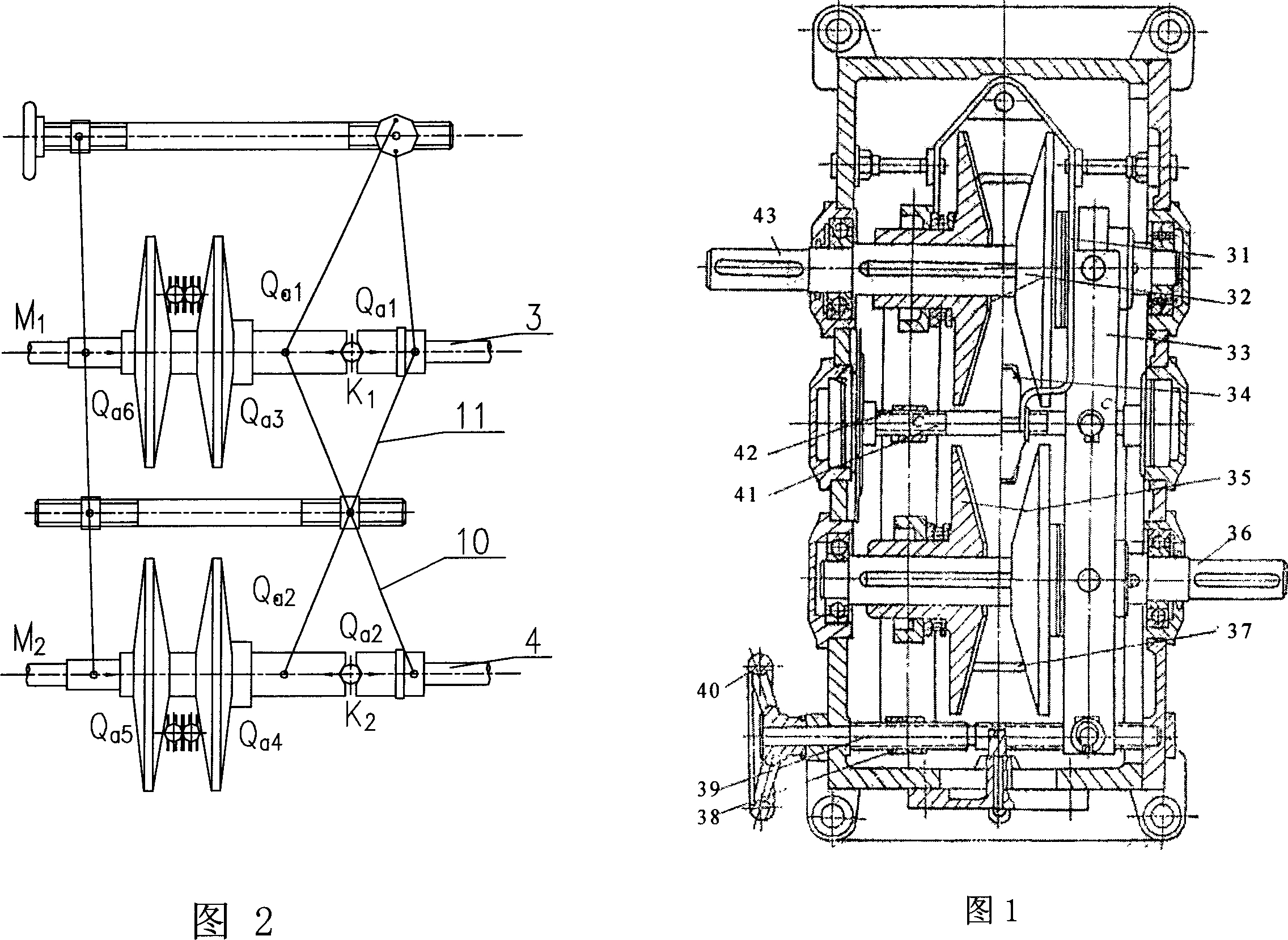

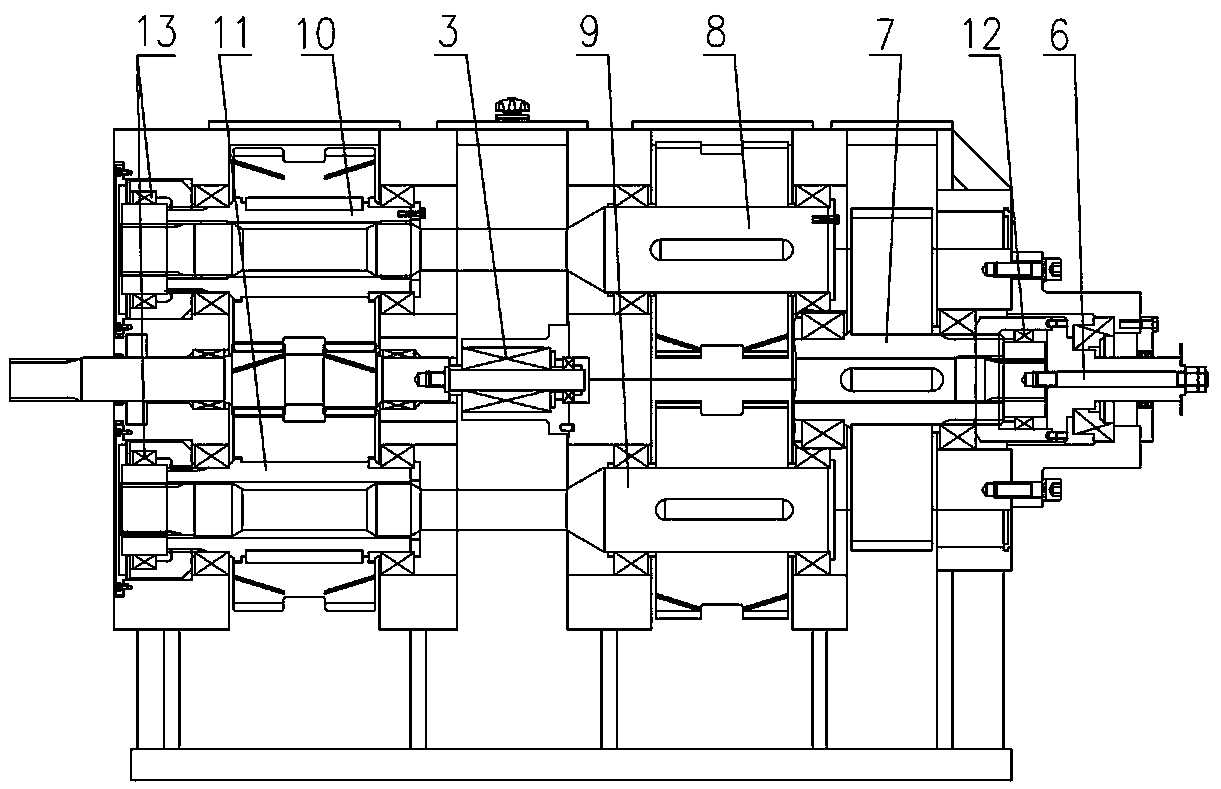

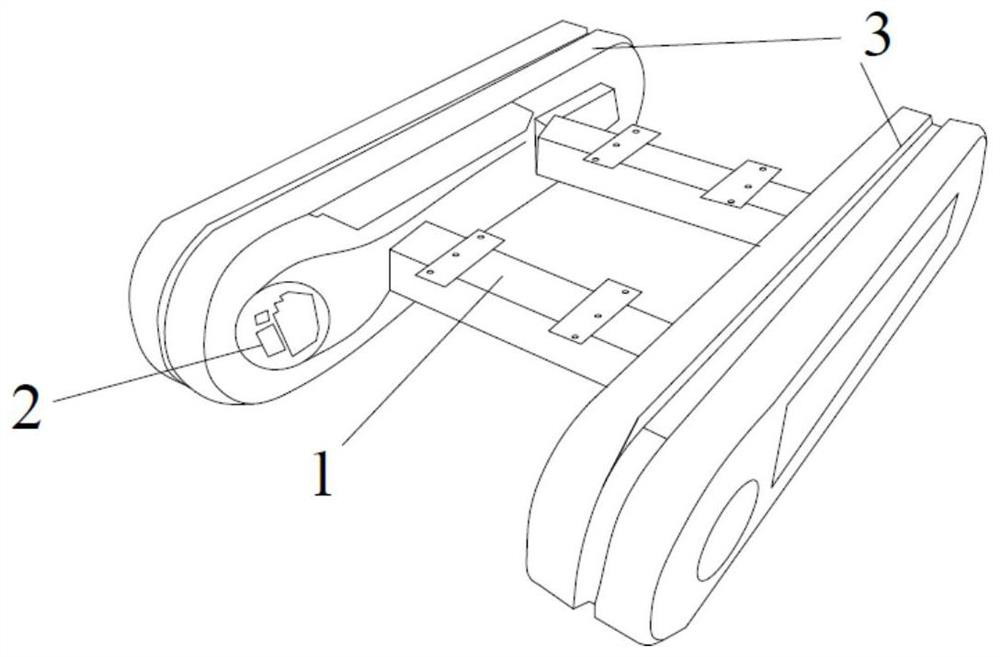

Shunting type high-speed tester

PendingCN111520439AMeet the requirements of high speed and high power outputImprove transfer powerToothed gearingsMechanical energy handlingShunt typesPower equipment

The invention discloses a shunting type high-speed tester, and belongs to the technical field of power equipment. The shunting type high-speed tester comprises a motor and a speed increaser, the speedincreaser comprises an input shaft, a first sun gear, a second sun gear, an output shaft and a plurality of planetary gear sets, and a planetary gear mechanism is adopted as a main part of the speedincreaser, so that the stability of power transmission is improved, power shunt and power confluence are realized, two-stage transmission is achieved accordingly, and the transmission ratio is increased; and meshing is achieved between the sun gears and planet gears through herringbone gear teeth, so that the transmission power of the planet gear mechanism is improved, and finally the output powerof the output shaft is improved. The combination of the planet gear mechanism and the herringbone gear teeth meets the requirement of the high-speed tester for high-speed and high-power output on thewhole.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

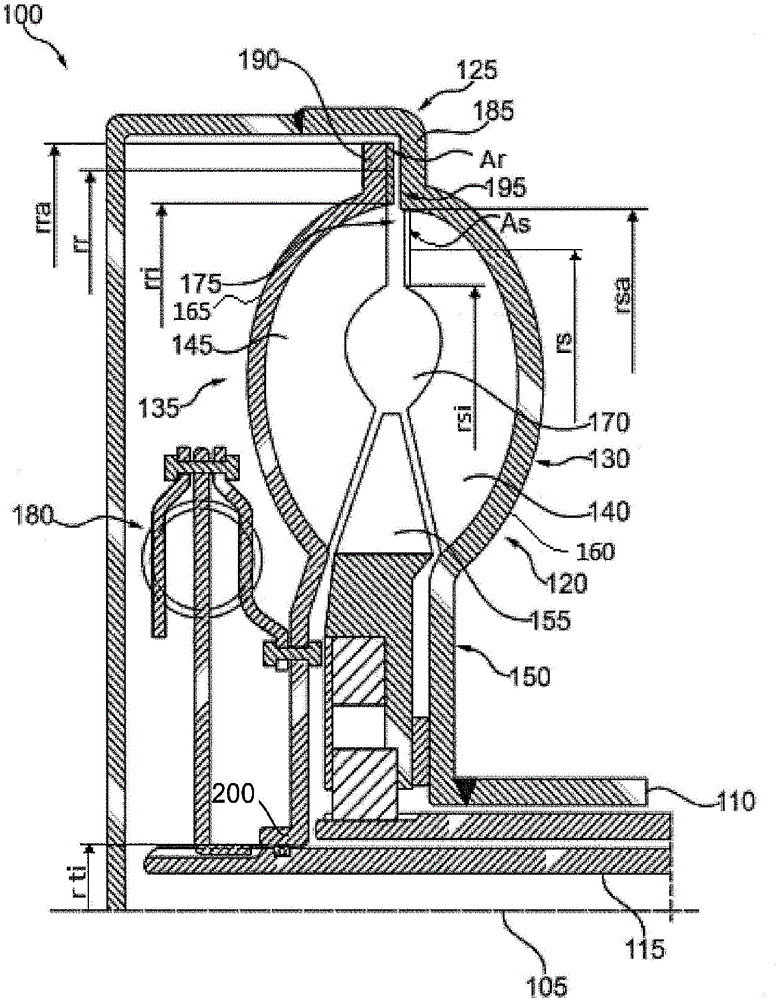

Device for transmitting torque

ActiveCN106574701AImprove transfer powerShorten access speedFriction clutchesFluid gearingsControl theoryTurbine

A device for transmitting torque comprises a hydrodynamic torque converter having a turbine and a pump, as well as a friction clutch which is connected in parallel to the torque converter, having a first and a second friction partner. In this context, the first friction partner is produced integrated with the pump and the second friction partner integrated with the turbine. A ring-shaped friction section, on which the friction elements can be axially engaged with one another, and a ring-shaped flow section, on which vanes of the pump and of the turbine are axially facing one another, are dimensionally adapted to one another in order to realize a balanced transmission behavior.

Owner:SCHAEFFLER TECH AG & CO KG

Chained oscillating tooth stepless speed change device

The invention discloses a chained oscillating tooth stepless speed change device. The chained oscillating tooth stepless speed change device comprises a metal chain, a driving shaft and a driven shaft; a fixed conical disk and a corresponding movable conical disk are arranged on the driving shaft and the driven shaft respectively; three groups of equant dovetail grooves which are perpendicular to a rotation direction are formed on the conical disks respectively; the dovetail grooves on the fixed conical disk correspond to those of the movable conical disk; dovetail blocks on oscillating tooth seats are embedded into the corresponding dovetail grooves on the conical disks; the wedge grove surfaces of each of oscillating tooth bodies and each of the oscillating tooth seats are rubbed and combined through an elastomer and by using an ejector rod and a compression plate so as to finish constant-speed transmission; and when the fixed conical disk and the movable conical disk approach and separate, three groups of equant oscillating tooth seats radially move at equal radii, the working radii of the oscillating tooth seats are changed, simultaneously the elastomer is compressed by a speed regulation plate to separate the oscillating tooth bodies and the oscillating tooth seats, and the oscillating tooth bodies freely move to be meshed with a chain randomly, so that the aim of changing the speed is fulfilled, friction transmission is guaranteed when speed is changed, gear transmission is guaranteed when speed is constant, and transmission power, torque and mechanical efficiency are greatly improved.

Owner:郭质刚

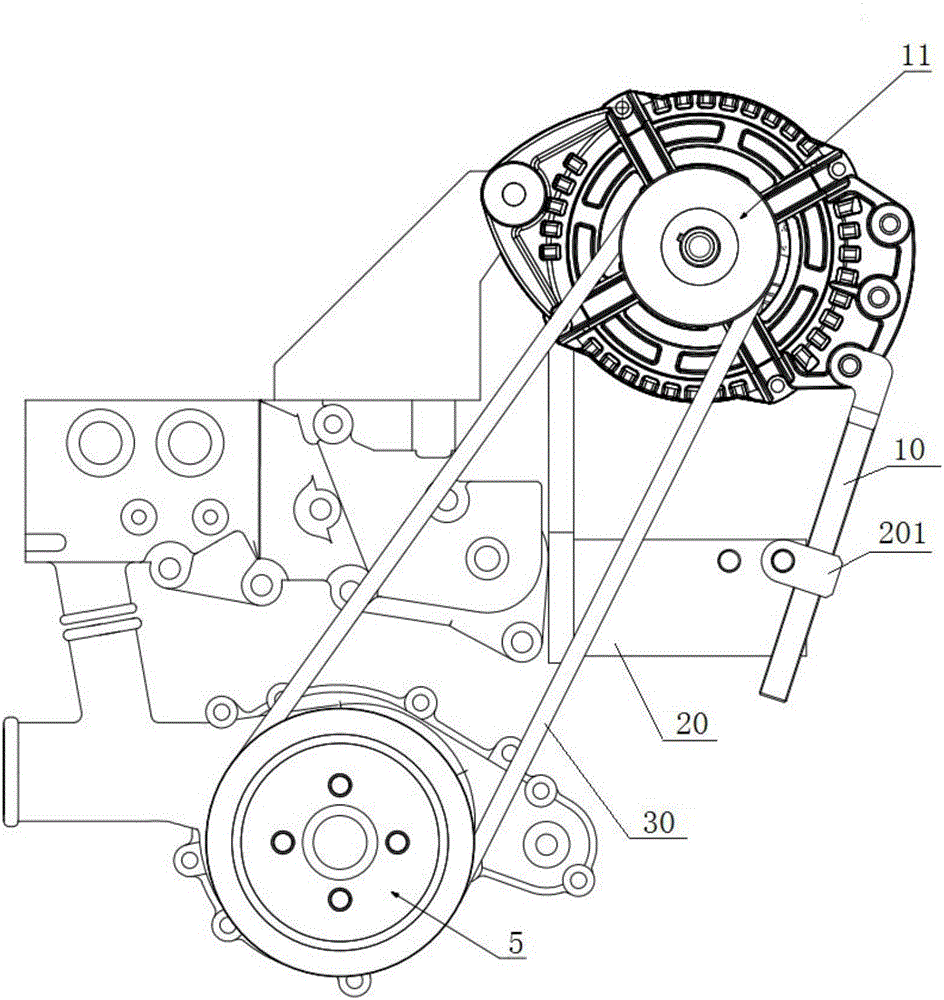

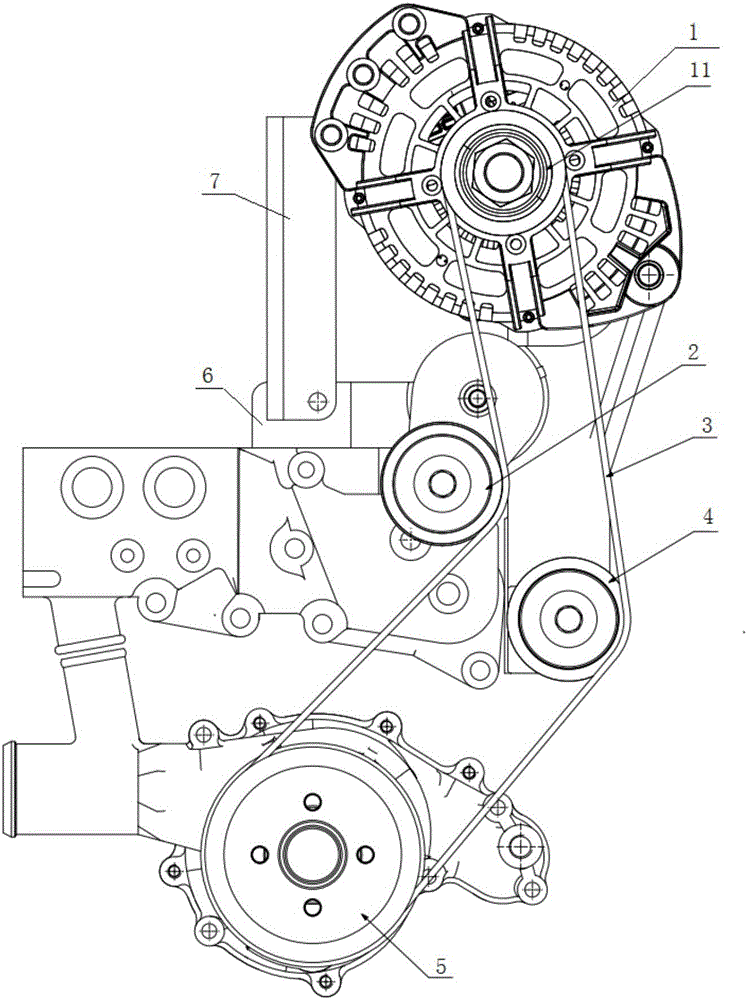

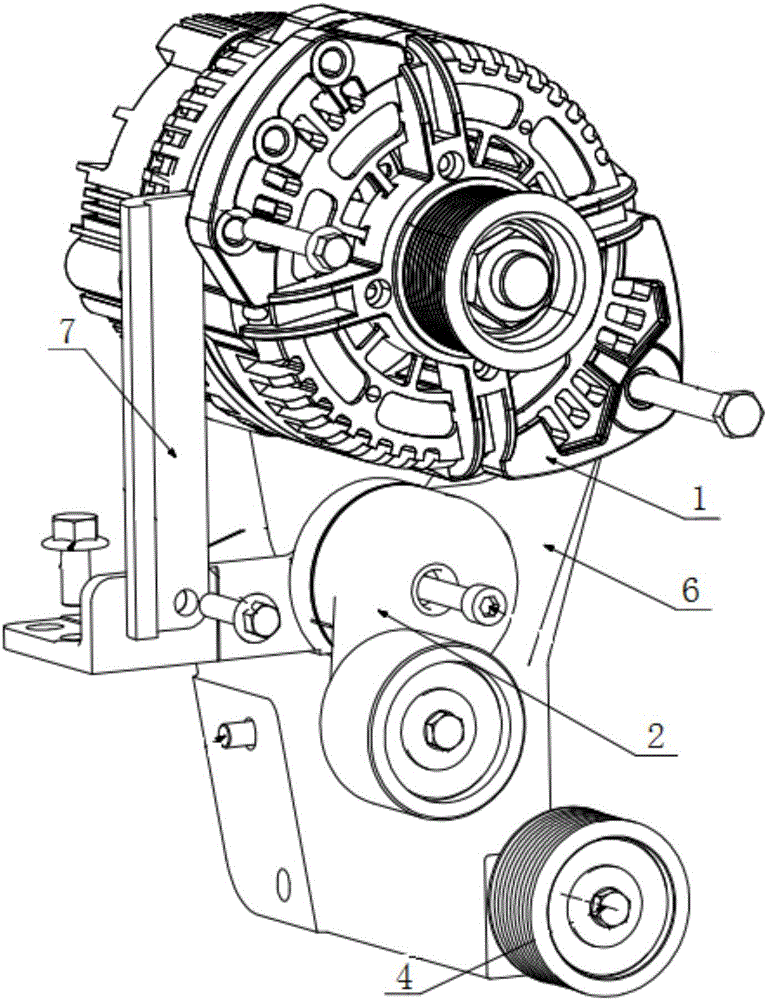

Pulley train structure of single generator at front end of engine

ActiveCN106194425AFlexible adjustment of tensionGood coplanarityMachines/enginesTransmitted powerIdler-wheel

Disclosed is a pulley train structure of a single generator at the front end of an engine. The pulley train structure comprises a generator belt pulley, a water pump additional belt pulley, a tensioning pulley and an idle pulley, wherein the water pump additional belt pulley is arranged obliquely below the generator belt pulley, the tensioning pulley is arranged on the inner side of the space between the generator belt pulley and the water pump additional belt pulley, and the idle pulley is arranged on the outer side of the space between the generator belt pulley and the water pump additional belt pulley. A poly V-belt passes through the generator belt pulley, the tensioning pulley, the water pump additional belt pulley and the idle pulley in sequence, and the tensioning pulley tightly presses the poly V-belt in the counter-clockwise direction. According to the pulley train structure, due to the fact that a pulley train is connected through the poly V-belt, the size of the generator belt pulley can be reduced, the transmitted power is improved, and the arrangement requirements of high-power generators are met; and the tensioning pulley and the idle pulley are used for flexibly adjusting the tension of the belt, so that the requirements of the high-power generators are met.

Owner:GUANGXI YUCHAI MASCH CO LTD

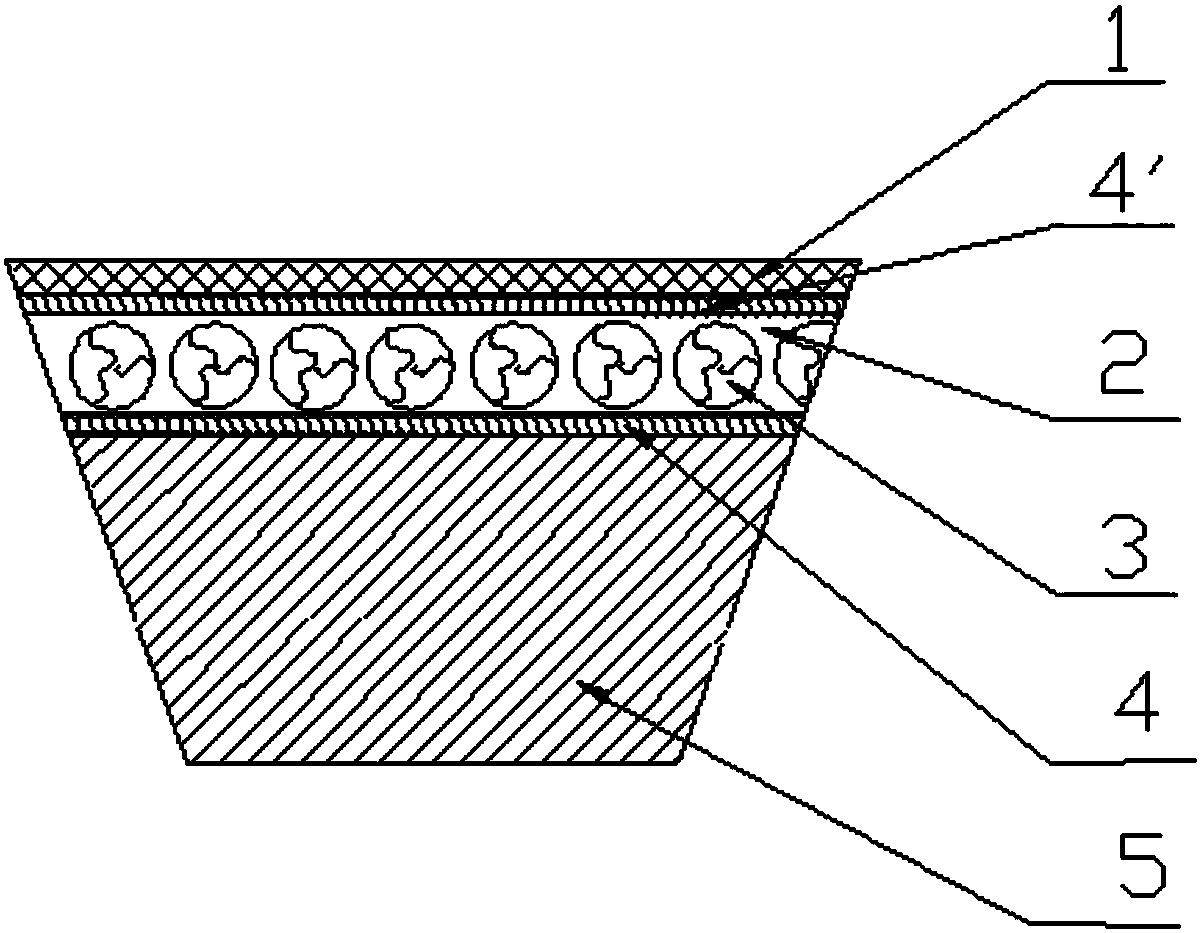

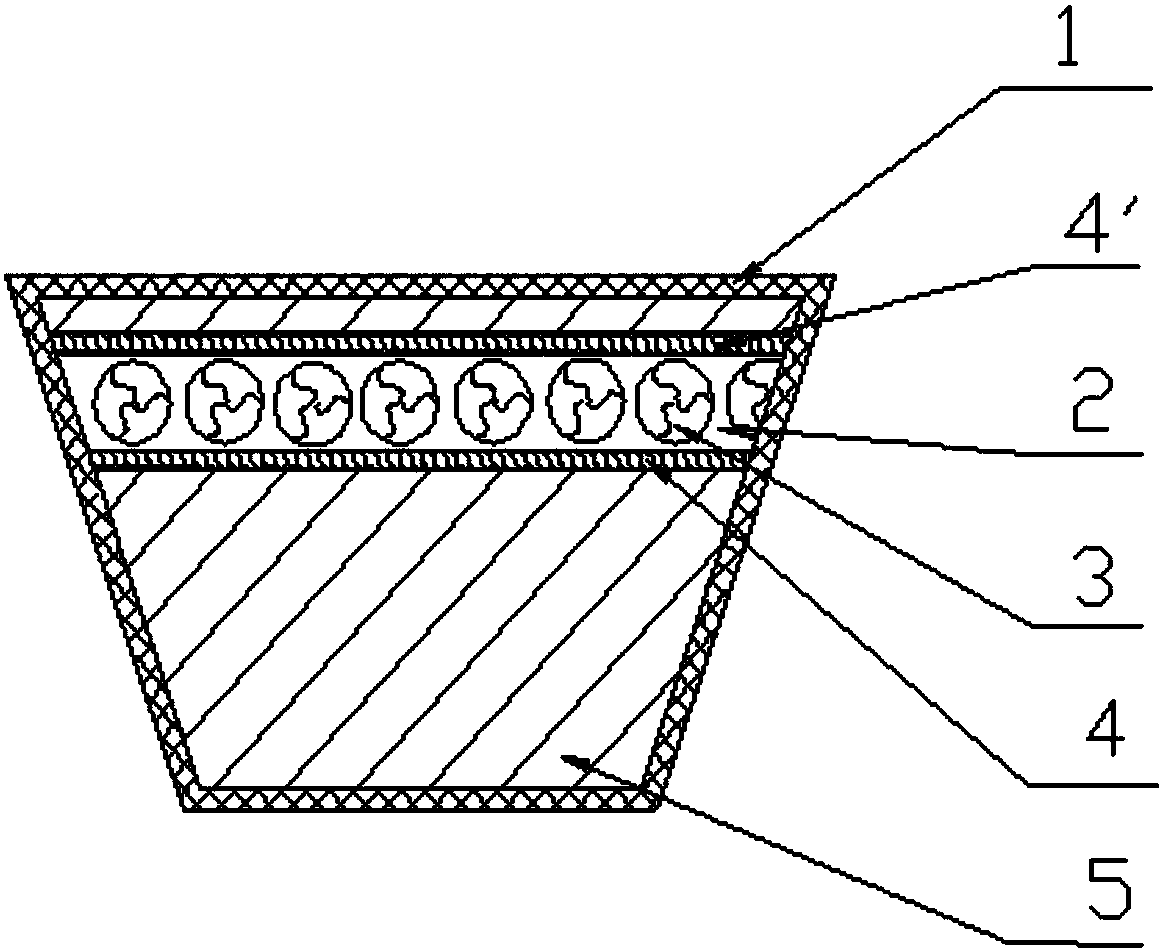

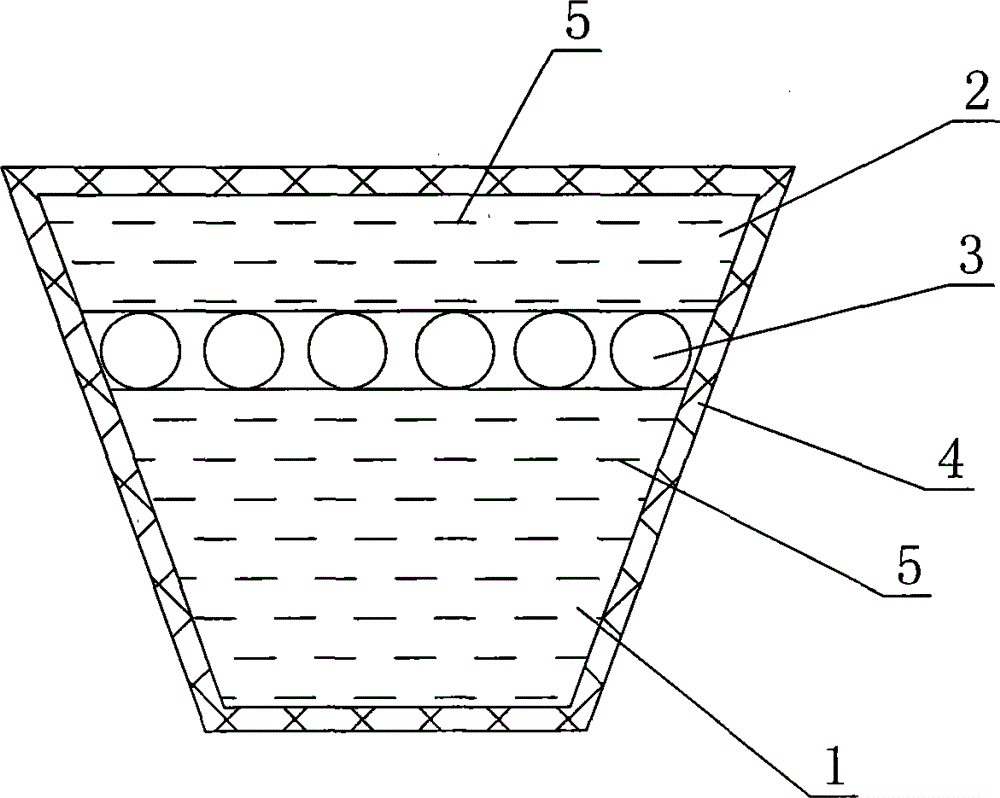

Reinforced V belt

The invention discloses a reinforced V belt. The reinforced V belt comprises a glue coating fiber fabric layer, a tensile body core wire layer, a bonding glue layer and a compression glue layer; the bonding glue layer is filled in the tensile body core wire layer; and hardened tire fabrics are respectively arranged between the tensile body core wire layer and the glue coating fiber fabric layer and between the tensile body core wire layer and the compression glue layer. compared with the prior art, the hardened tire fabrics with a certain stiffness are respectively arranged on the tensile bodycore wire layer up and down, so that the transverse rigidity of the V belt is greatly improved, the deformation of the belt is reduced, the fatigue resistance is improved, the transfer power is increased, the stress centralization problem of the compression glue layer is prevented, the transmission stability and the reliability are improved, and the service life is prolonged.

Owner:无锡市贝尔特胶带有限公司

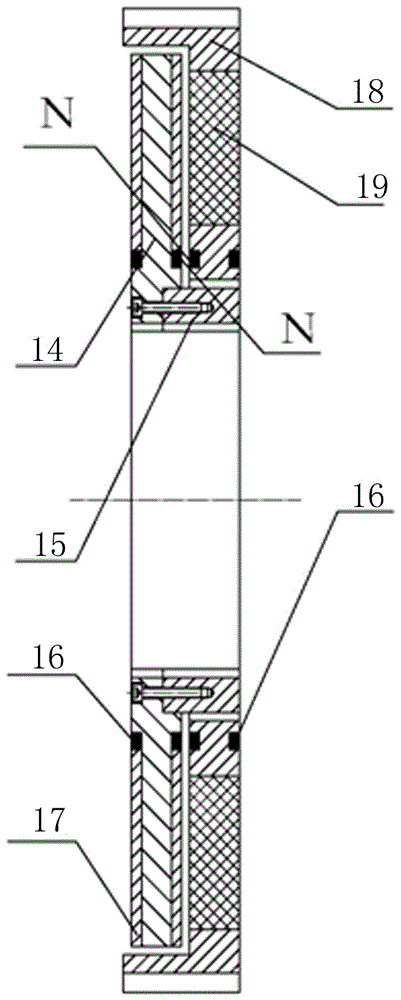

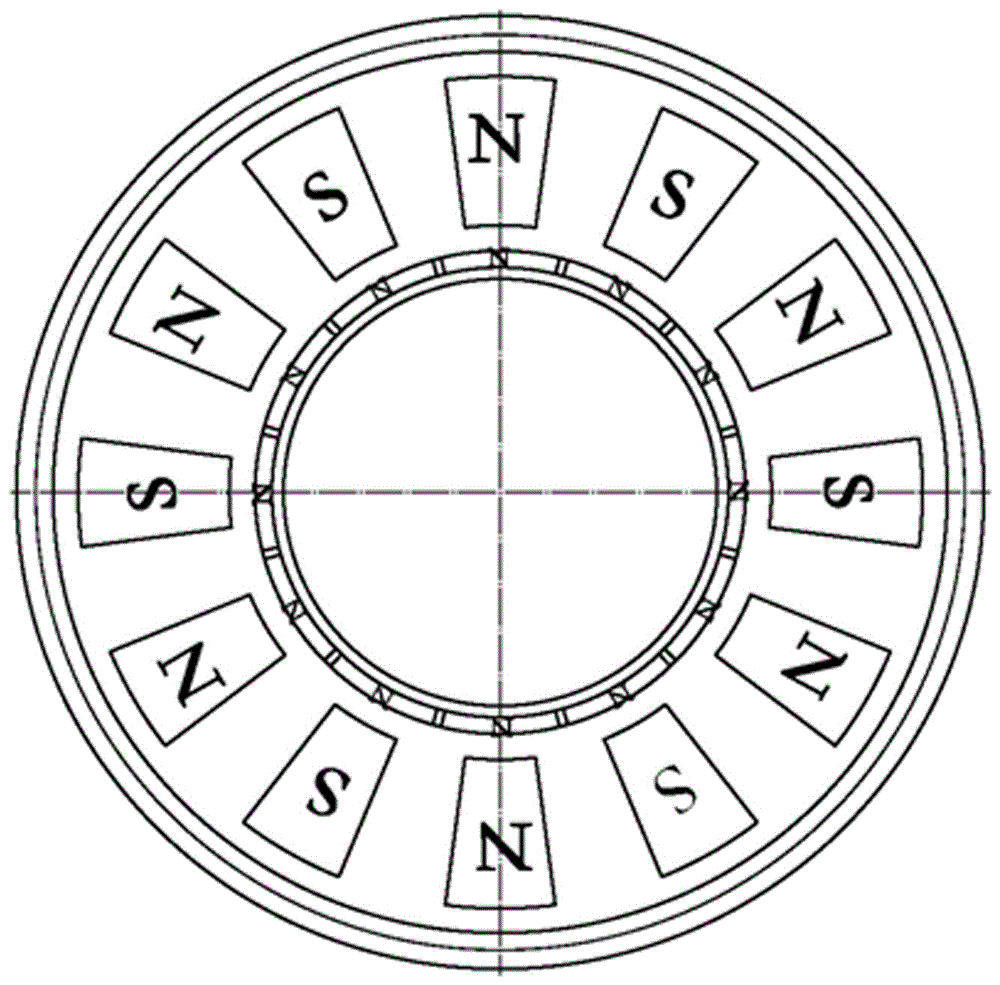

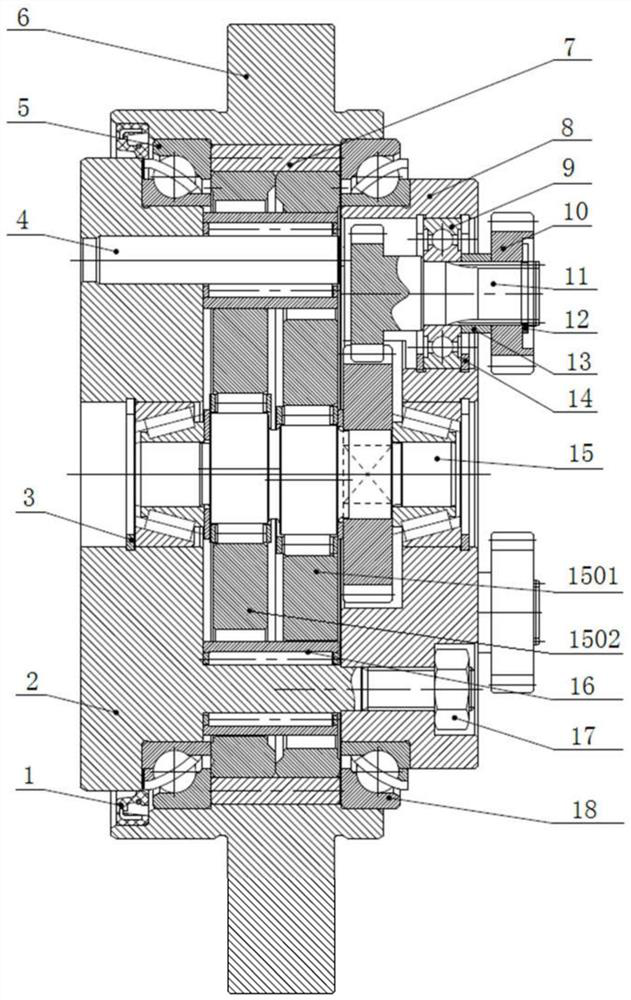

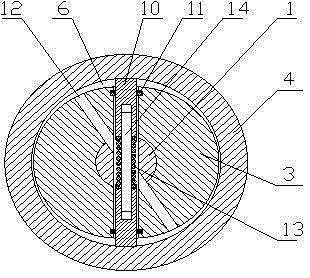

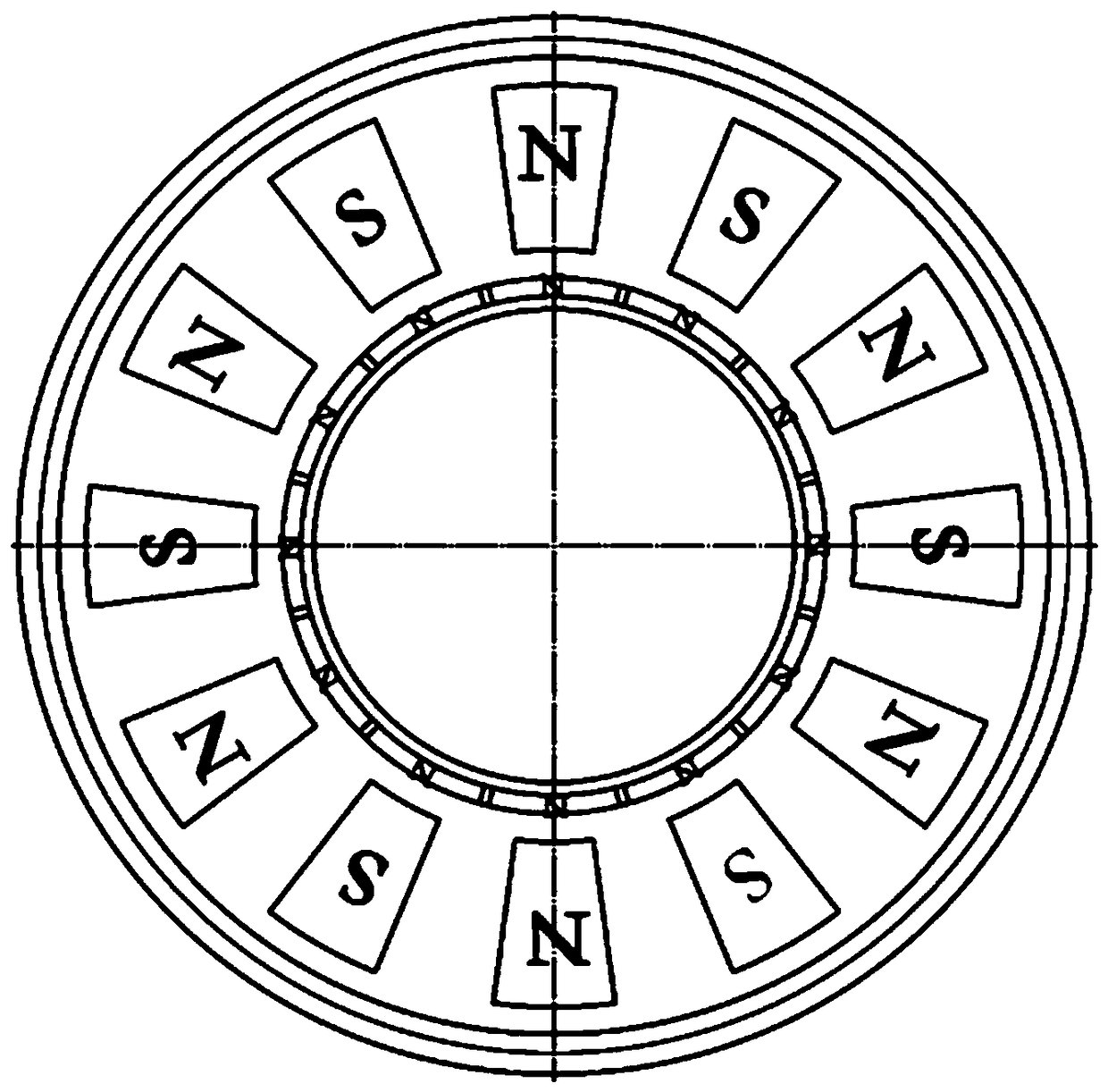

A multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling

ActiveCN106452007AAvoid collisionAvoid wear and tearDynamo-electric gearsElectrical conductorElectric machine

The invention belongs to the field of mechanical transmission. In order to use the shaft coupling to limit a transmission torque of a motor and a transmission system, to protect transmission components from shock overload and to ensure the normal operation of a host machine, a multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling is thus provided. The multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling comprises an input shaft sleeve, a transition connection disc, a left auxiliary casing, a spline sleeve, an output spline shaft, etc. Several magnet plates and conductor plates which are alternately stacked are arranged in the spline sleeve. Each of the magnet discs is circumferentially embedded with an even-number of permanent magnets in which N and S poles are alternately arranged. Permanent magnets of the adjacent magnet discs are axially opposed, and magnetic poles of the adjacent magnet discs are opposite. Inner rings of the two adjacent surfaces of each two adjacent conductor disc and magnet disc are provided with a plurality of small magnets axially opposed and having the same magnetic poles, so that the magnet plate and the conductor plate are not in contact due to the repulsive force. The multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling of the invention employs a multi-disc type structure, so that the permanent-magnetic driving power can be raised without increase in the radial structural dimension of a permanent magnetism transmission device. The multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling can be widely applied to occasions where the radial space is limited and the axial direction space is large.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

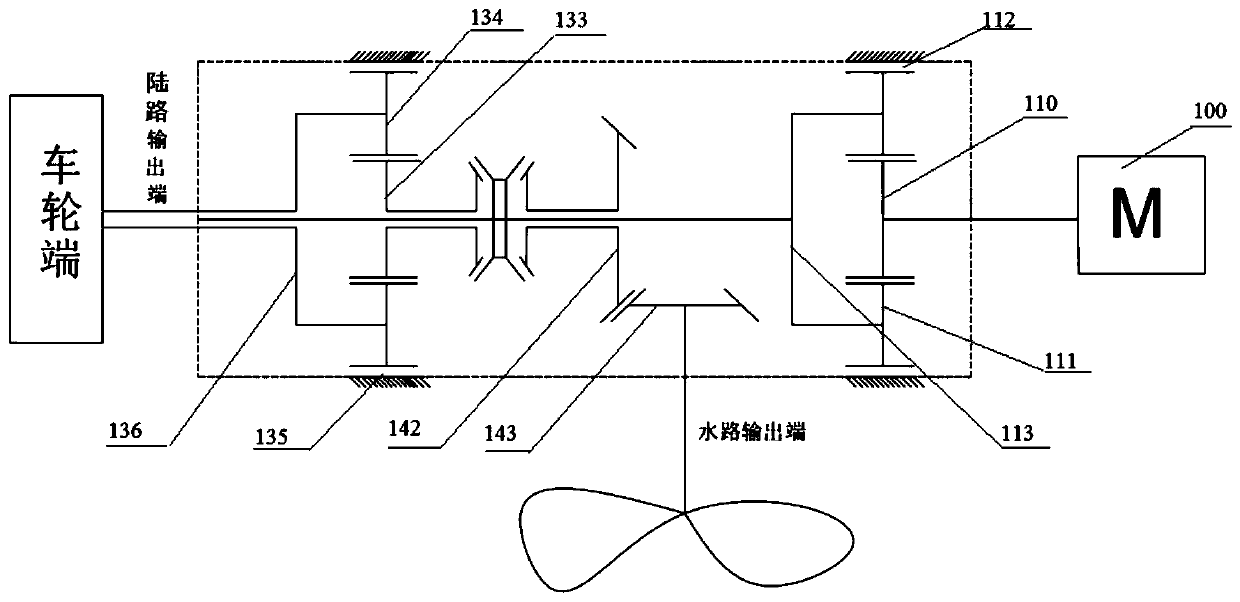

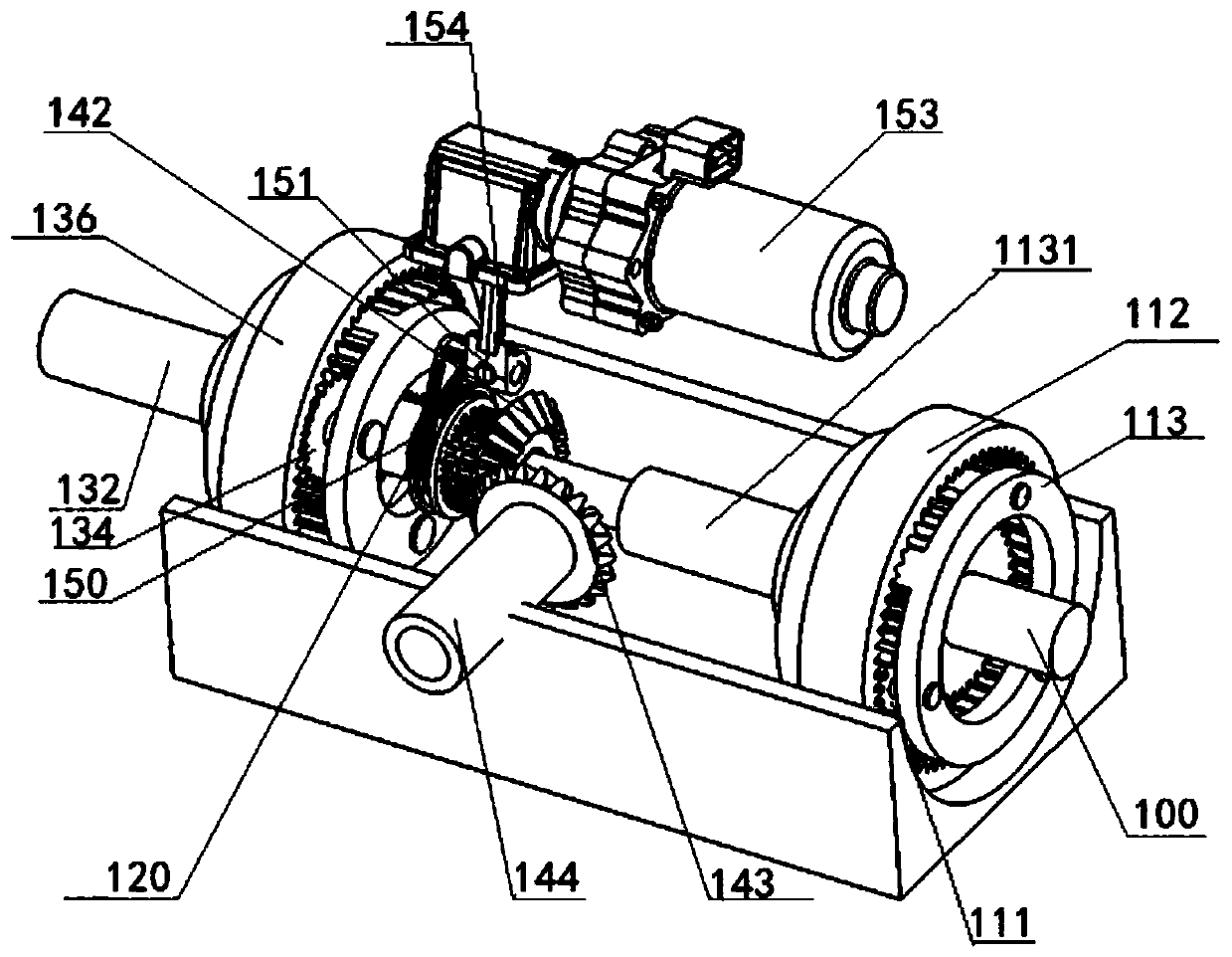

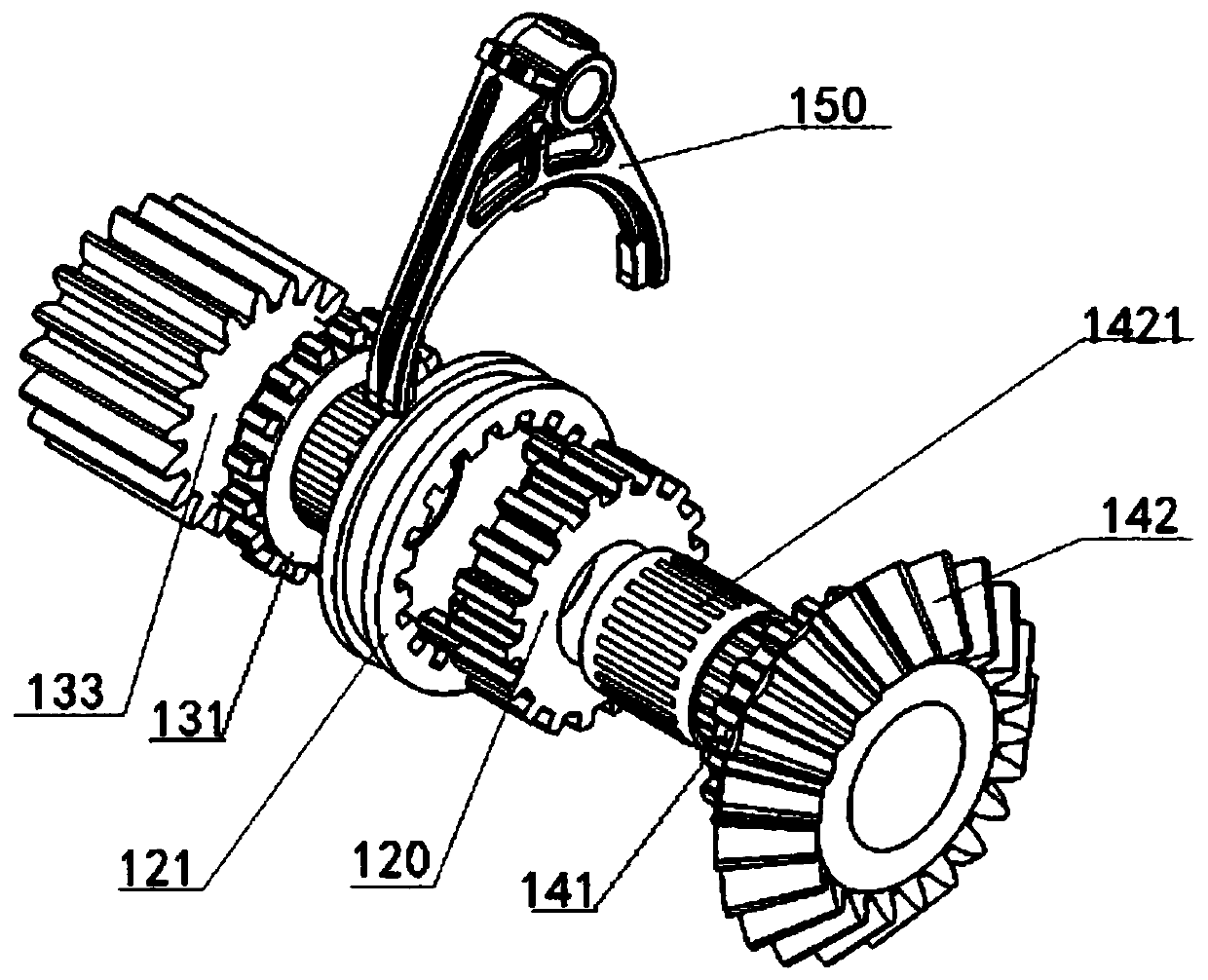

Double-planet-gear-set amphibious speed reducer, amphibious vehicle and control method thereof

PendingCN110154743ARealize power switchingSimple structureAmphibious vehiclesControl devicesEngineeringReducer

The invention discloses a double-planet-gear-set amphibious speed reducer. The double-planet-gear-set amphibious speed reducer comprises a power input shaft, a first sun wheel, a plurality of first planet wheels, a first gear ring, a first planet carrier, a clutch, a meshing sleeve, a land route output end and a water route output end, wherein the first sun wheel is coaxially and fixedly connectedwith the power input shaft, the first planet wheels are circumferentially arranged on the outer side of the first sun wheel, and the first planet wheels are in meshed transmission with the first sunwheel; the first gear ring is arranged concentric with the first sun wheel, and the first gear ring is in meshed transmission with the first planet wheels; the first planet carrier is rotationally connected with a wheel shaft of each first planet wheel in the circumferential direction, and a rotating column vertically extends from the center of the side, away from the power input shaft, of the first planet carrier; the clutch is coaxially and fixedly connected with the rotating column, and meshing teeth are arranged on the outer side of the clutch in the circumferential direction; the meshingsleeve is meshed with the clutch, synchronously rotates along with the clutch, and can move along the axis of the clutch. The invention further provides an amphibious vehicle which adopts the double-planet-gear-set amphibious speed reducer. The invention further provides a control method of the amphibious vehicle.

Owner:JILIN UNIV

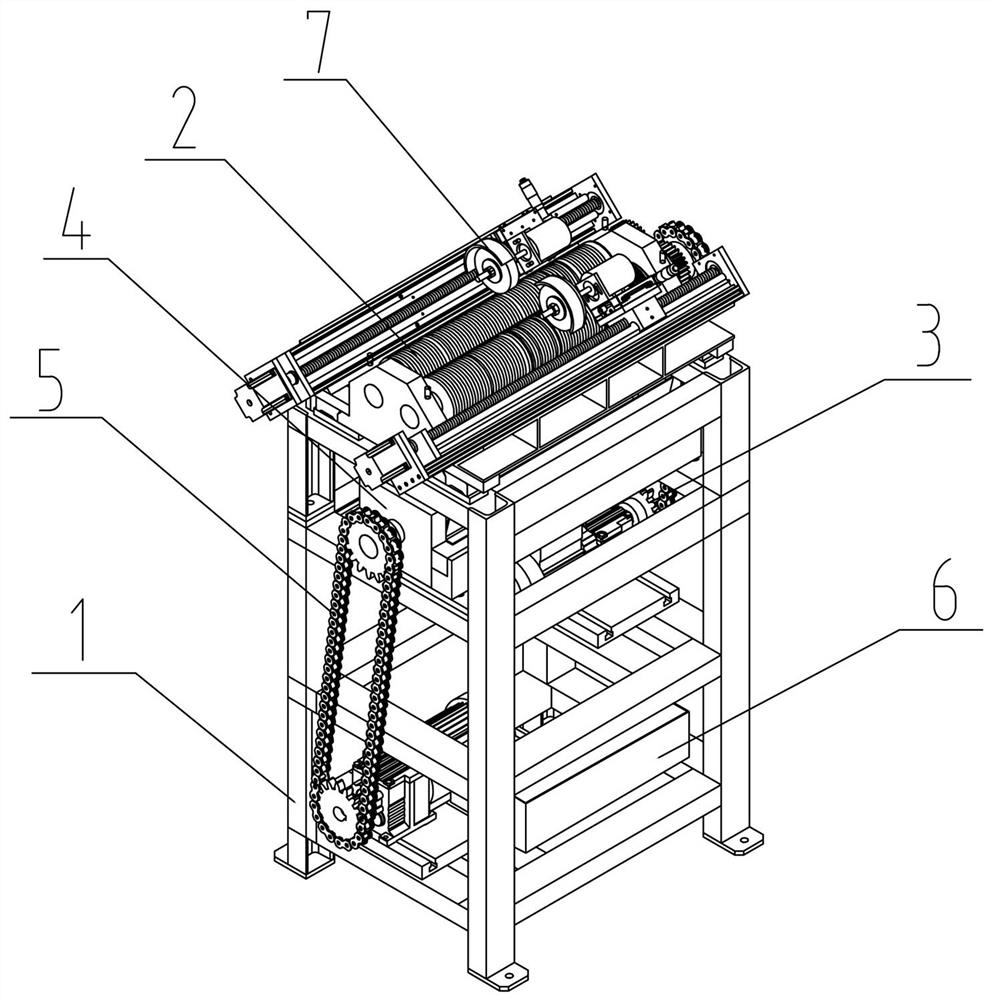

Tobacco cutter with knife grinder and application method of tobacco cutter

ActiveCN112405131AFully cutImprove work efficiencyTobacco treatmentGrinding drivesKnife bladesStructural engineering

The invention relates to a tobacco cutter with a knife grinder and an application method of the tobacco cutter, and relates to the field of tobacco cutting. The tobacco cutter specifically comprises arack, a longitudinal cutting knife set used for longitudinally cutting cut tobacco, a first transmission device used for driving the longitudinal cutting knife set to achieve longitudinal cutting, atransverse cutting knife set used for transversely cutting the cut tobacco, a second transmission device used for driving the transverse cutting knife set to achieve transverse cutting, a material receiving box used for loading the cut tobacco being cut and the knife grinder used for grinding the longitudinal cutting knife set. Tobacco sheets are cut in a combined manner through the longitudinal cutting knife set and the transverse cutting knife set, the tobacco sheets can be cut more sufficiently and evenly, the longitudinal cutting knife set can be directly ground through the knife grinder capable of being dismounted on the rack, the operation that a knife roller is dismounted from the tobacco cutter and then taken into a knife grinding mechanism to grind blades is not needed any more, and time and manpower are saved.

Owner:HUBEI CHINA TOBACCO IND +1

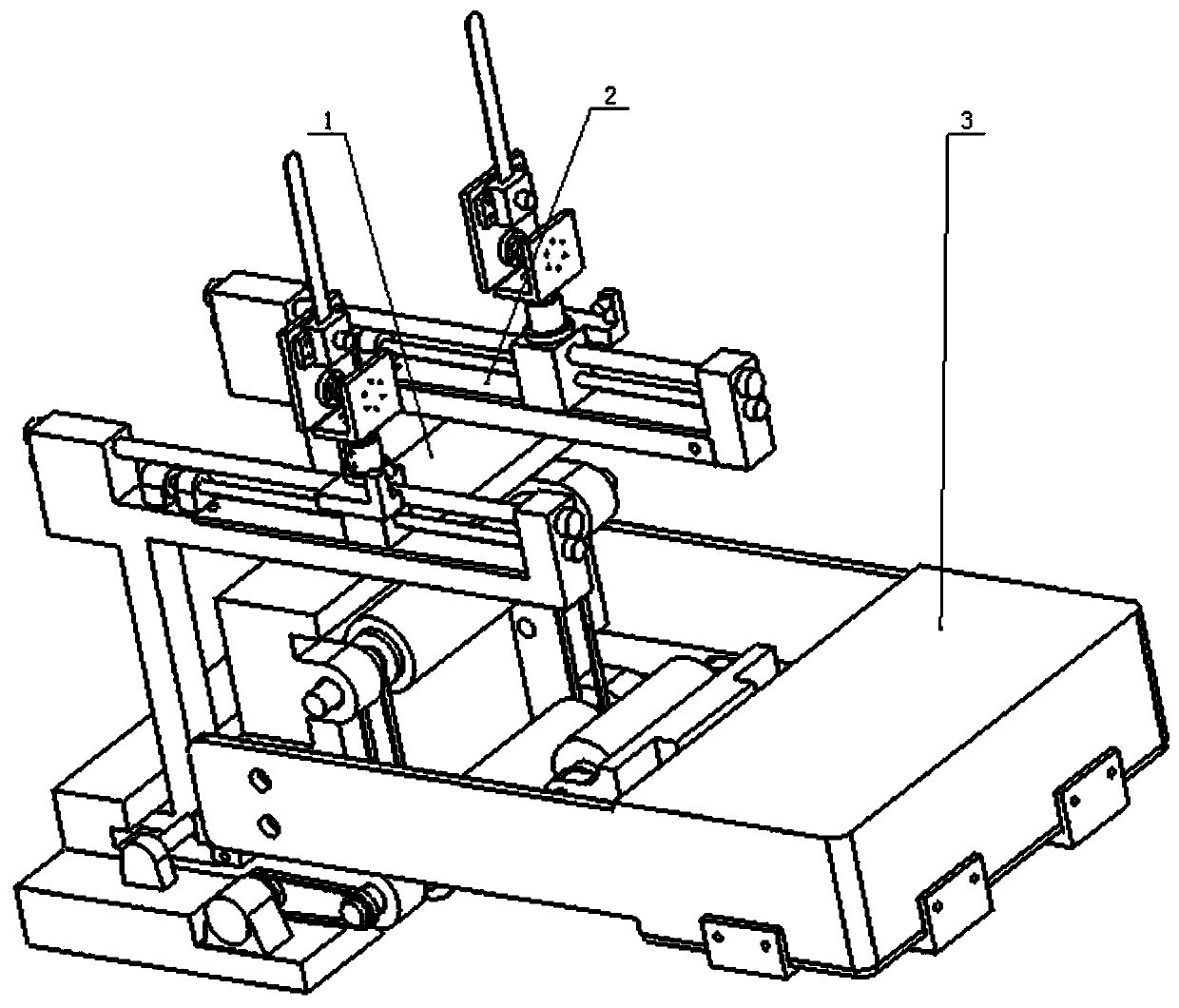

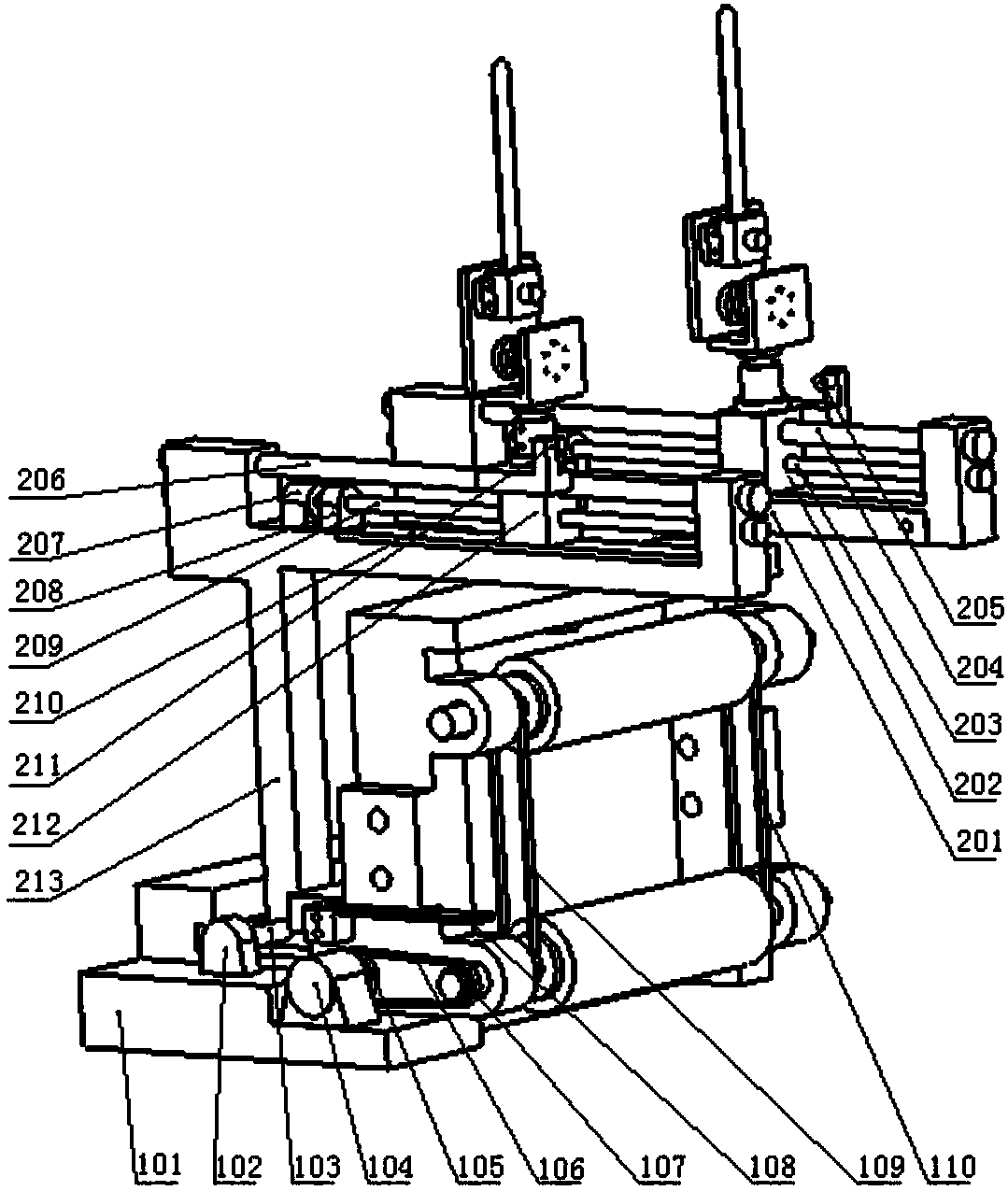

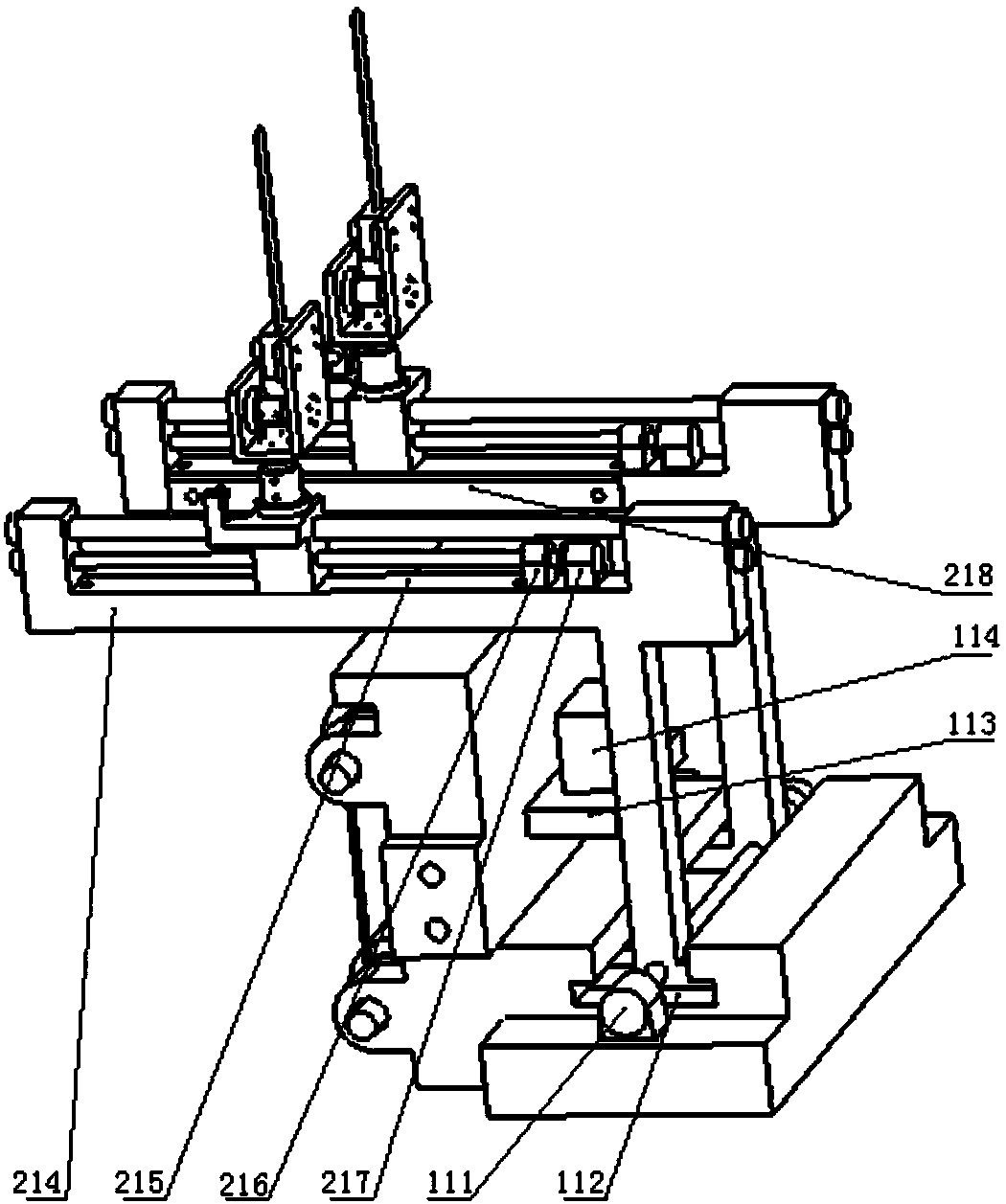

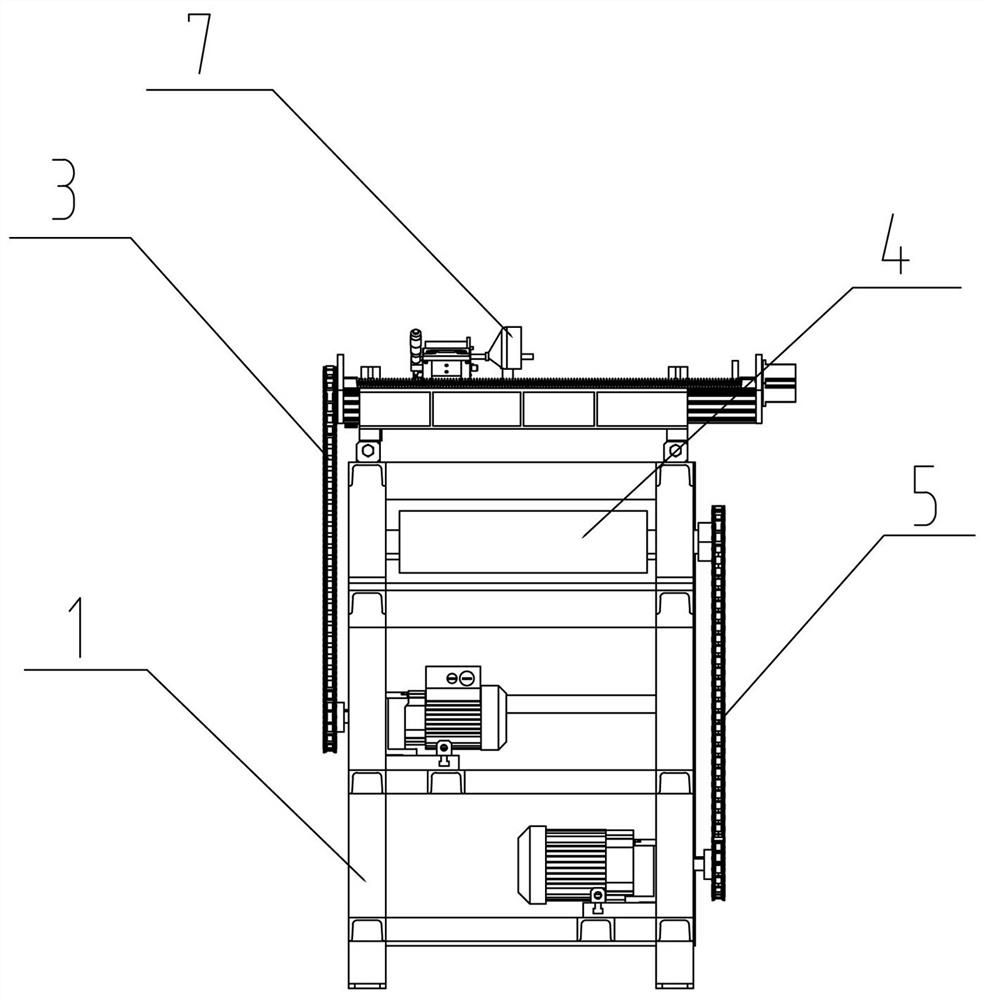

An environment-friendly cleaning device for small advertisements on the wall

ActiveCN109091085BSmall transfer powerReduce transfer efficiencyCarpet cleanersFloor cleanersProcess engineeringIndustrial engineering

The invention provides an environment-friendly cleaning device for small wall advertisements, which belongs to the technical field of environment protection. The technical solution is: an environment-friendly cleaning device for small wall advertisements, including a lifting mechanism (1) and a cleaning mechanism (2) arranged on the lifting mechanism (1). The beneficial effects of the present invention are: the present invention adopts the lifting mechanism and the cleaning mechanism to remove the small advertisements on the wall, which solves the problems of low work efficiency and high labor intensity of manual removal of small advertisements on the wall, and can clean the small advertisements on the wall at different heights. The small advertisements are cleared, and the application range is wide. The self-adhesive clearing agent is used for clearing, and the clearing is relatively thorough, avoiding problems such as scratches on the wall.

Owner:浙江五峰汽车轴承制造有限公司

Ultralow-speed-ratio high-rigidity high-precision cycloidal-pin wheel planetary transmission speed reducer

PendingCN114001125AIncreased torsional rigidityThe overall arrangement is compactToothed gearingsGearing detailsCrankEngineering

The invention discloses an ultralow-speed-ratio, high-rigidity high-precision cycloidal-pin wheel planetary transmission speed reducer, and belongs to the field of mechanical transmission devices. Three spline gear assemblies are evenly arranged on the input planet carrier in the circumferential direction, the gear end of the spline gear shaft is arranged in the input planet carrier, and the planet gear is installed at the shaft end of the spline gear shaft, located outside the input planet carrier and used for being in meshing transmission with an external input gear to form first-stage transmission; a crankshaft gear assembly comprises a crankshaft, a center gear and a cycloidal gear, wherein the center gear and the cycloidal gear are sequentially installed on the crankshaft; the central gear is in meshing transmission with the gear end of the spline gear shaft to form second-stage transmission; and the crankshaft drives the cycloidal gear to be meshed with the roller pin in the pin wheel housing to form third-stage transmission, and the cycloidal gear drives the planet carrier to achieve power output. The first-stage transmission and the second-stage transmission adopt the structure that the same planet gears are uniformly distributed in the circumferential direction of the central gear, so that the whole machine is extremely compact in arrangement and high in transmission power, and the three-stage transmission has an ultra-low speed ratio.

Owner:浙江环动机器人关节科技有限公司

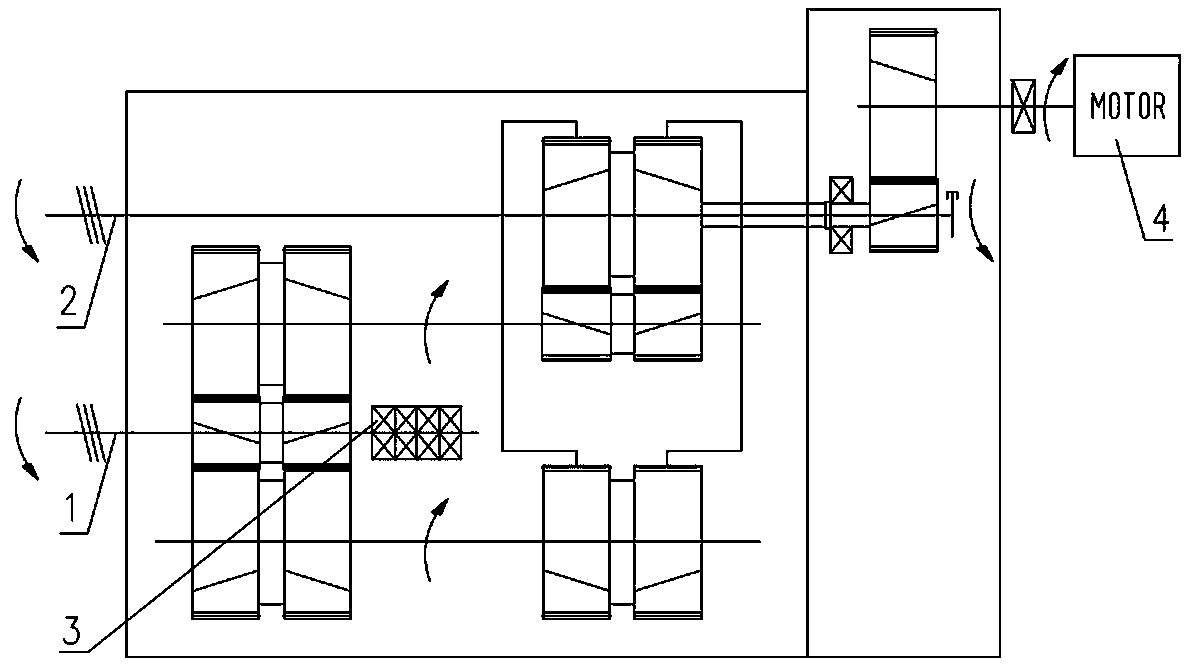

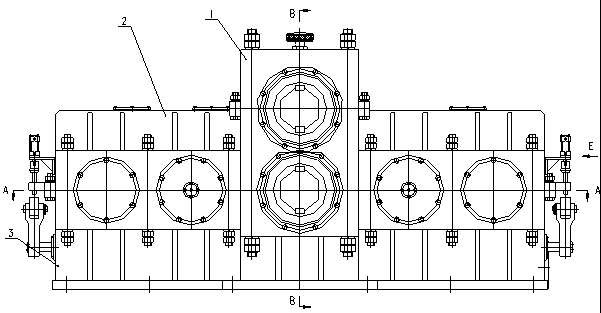

Main drive gearbox of twin-screw extrusion machine

InactiveCN109854722ASmall transfer powerHigh rotation accuracyGearing detailsEngineeringControl theory

The invention discloses a main drive gearbox of a twin-screw extrusion machine. The extrusion machine comprises the gearbox and a motor which are electrically connected; the gearbox adopts the transmission mode of primary shunting and secondary interflowing of a herringbone tooth gear pair; and the gearbox comprises a first output shaft, a second output shaft, a series bearing, an input shaft, a pull rod, a second shaft system, a third shaft system, a fourth shaft system, a fifth shaft system, a sixth shaft system, a first expanding sleeve adjusting mechanism and a second expanding sleeve adjusting mechanism. On the condition of given small central moment, when a certain rotation speed is input, two same rotation speed and torque with high rotation precision are output at the same time inthe same direction, and the transmission efficiency is twice that of a gearbox of the same specification.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

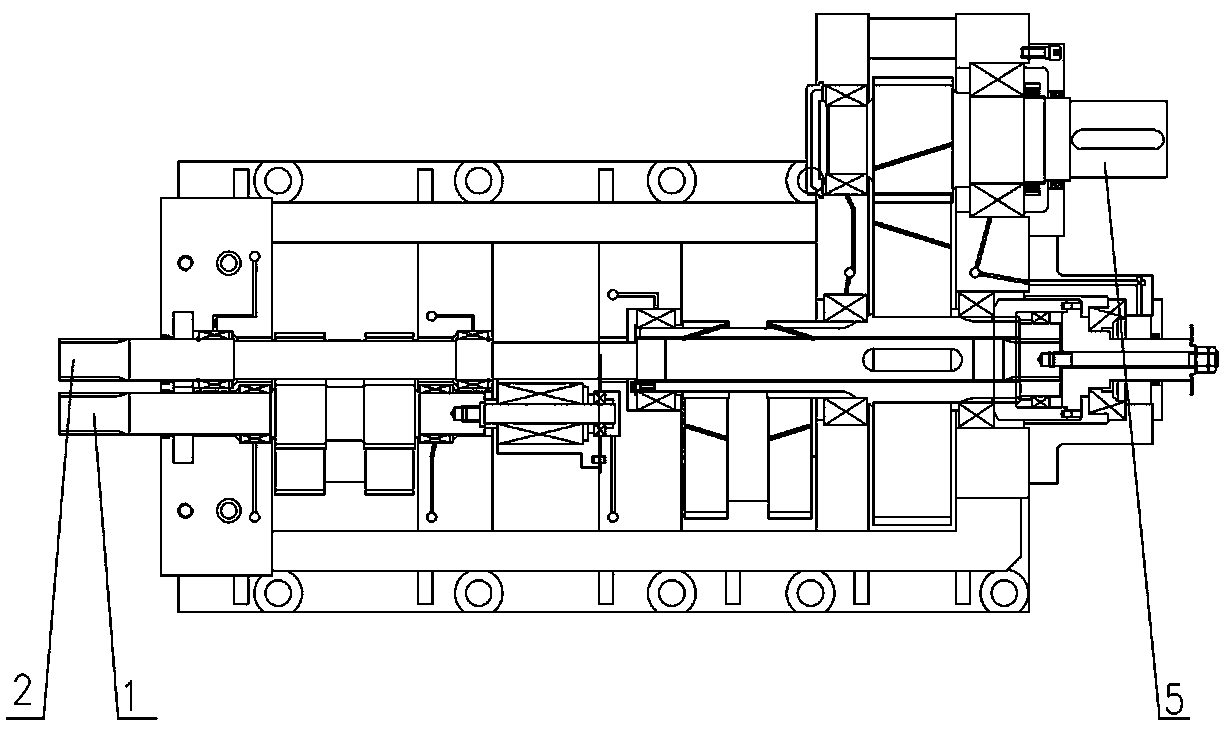

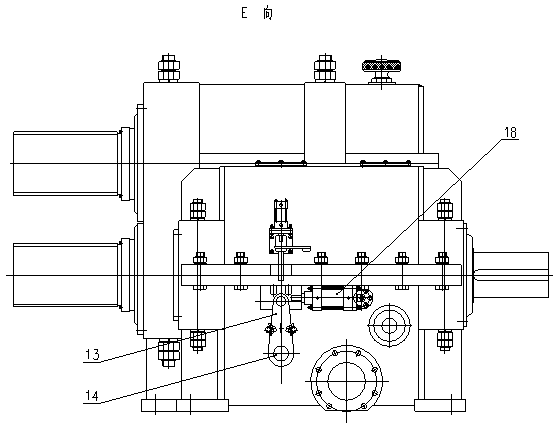

Divided flow type master transmission reduction gear box of hot rolling mill

ActiveCN102699037AImprove transfer powerReduce the standard of mechanical strengthRolling mill drivesMetal rolling arrangementsEngineeringLow speed

The invention relates to a divided flow type master transmission reduction gear box of a hot rolling mill. The box bodies of the reduction gear box comprise an upper box body, a middle box body and a lower box body; the output shafts of the reduction gear box comprise a long output gear shaft and a short output gear shaft; two independent drive systems with the same structures and parameters are symmetrically located on the two sides of the long output gear shaft; the short output gear shaft is supported between the upper box body and the middle box body through a bearing; the long output gear shaft and shafts in the independent drive system are supported between the middle box body and the lower box body through the bearing; the independent drive system comprises an input gear shaft and a middle gear shaft; a high and low speed gearshift mechanism is arranged on the middle gear shaft; a high and low speed shift gear in the high and low speed gearshift mechanism is engaged with a high and low speed gear in the input gear shaft; an output gear is mounted on the long output gear shaft through a key; a gear on the middle gear shaft is engaged with the output gear on the long output gear shaft; the gears on the long output gear shaft and the short output gear shaft are mutually engaged; and the high and low speed gearshift mechanism is arranged on the middle gear shaft and is synchronously adjusted through a synchronous gearshift device.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

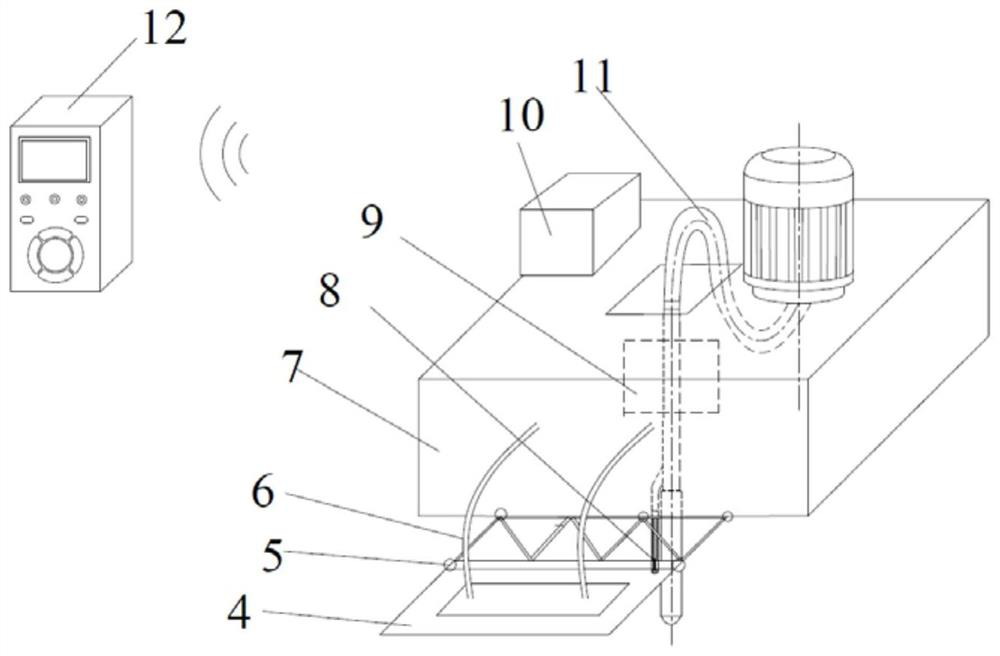

Intelligent concrete vibrating and plastering integrated equipment based on vibration wave signal control

PendingCN114575202AClosely arrangedSmooth motionRailway track constructionStructural engineeringRoad surface

The invention relates to intelligent concrete vibrating and plastering integrated equipment based on vibration wave signal control. The intelligent concrete vibrating and plastering integrated equipment is mainly composed of an advancing system, a vibrating working system, a plastering working system, a data processing center and other modules. The vibrating working system and the plastering working system can realize fine construction of vibrating and plastering under the control of the data processing center; the data processing center processes the collected vibration wave signals and judges the concrete vibration compaction degree according to the change rule of the vibration wave signals; the advancing system can achieve accurate adjustment of displacement and construction positions, and intelligent construction of a long-line structure is achieved. According to the invention, automatic and accurate construction in the whole process of concrete vibrating and plastering is realized, the device is suitable for plane structure concrete projects such as long-line continuous cast-in-place high-speed railway base plates, ballastless track beds, highway pavements and airport runways, and the concrete construction quality and the construction efficiency are improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Wedge squeeze soft start device based on magnetorheological fluid and shape memory alloy

InactiveCN103591234BImprove transfer powerGuaranteed delivery effectFriction gearingsDrive shaftShape-memory alloy

The invention discloses a wedge extrusion soft start device based on magnetorheological fluid and shape memory alloy, which comprises a driving shaft and a driven shaft, the driving shaft is provided with a magnetorheological fluid transmission mechanism, and the magnetorheological The hydraulic transmission mechanism includes a driving inner cylinder that is sleeved on the driving shaft and can rotate with the driving shaft, and a driven outer cylinder that is sleeved outside the driving inner cylinder and can transmit the torque output by the driving inner cylinder to the driven shaft. and an excitation coil capable of generating a magnetic field, a wedge-shaped working gap is formed between the active inner cylinder and the driven outer cylinder, and magnetorheological fluid is installed in the wedge-shaped working gap, and the magnetic field generated by the excitation coil can act on the wedge-shaped The magnetorheological fluid in the working gap enables the active inner cylinder to drive the driven outer cylinder to rotate through the magnetorheological fluid. The invention utilizes the extrusion strengthening effect of the magneto-rheological fluid to improve the transmission power of the soft start device; meanwhile, the invention assists in the transmission of torque through memory alloys, so that the transmission performance of the soft start device is more reliable.

Owner:CHONGQING UNIV OF TECH

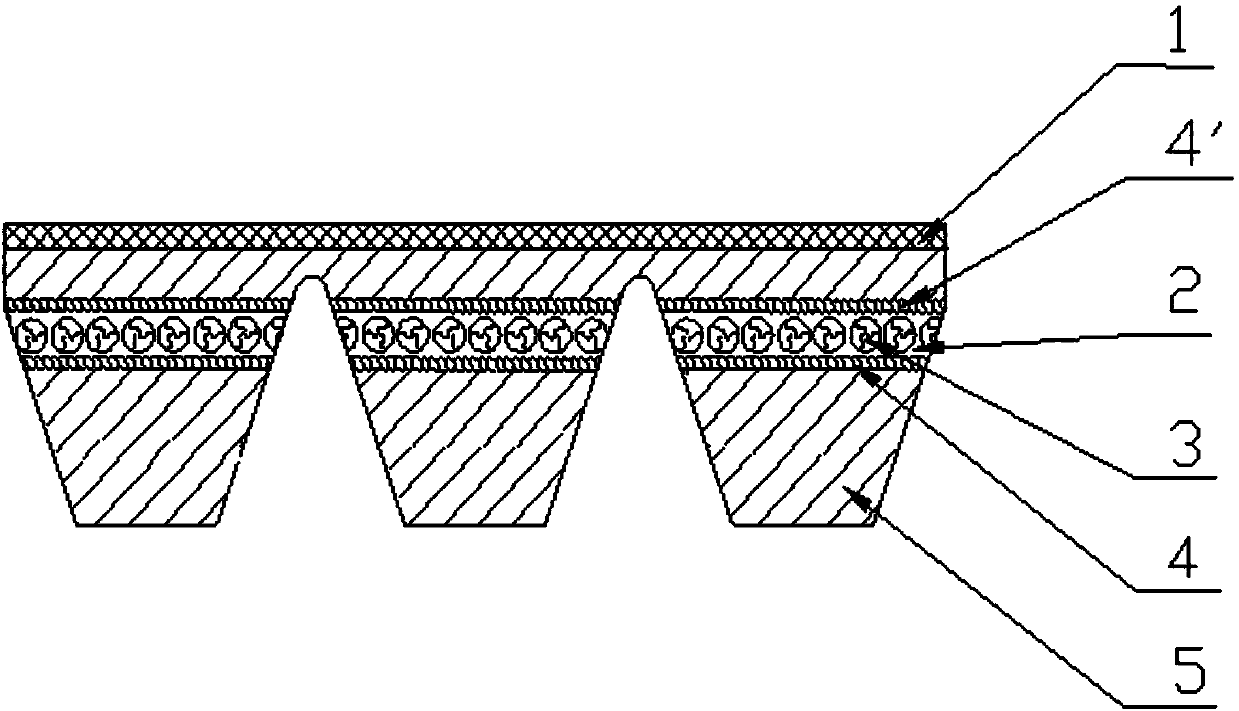

Special tape for new semi-feeding rice harvester

ActiveCN102155518BImprove impact resistanceImprove transfer powerV-beltsDriving beltsLateral stiffnessMechanical engineering

The invention discloses a special adhesive tape for a novel half-feeding rice harvester; the special adhesive tape is coated on a primer and a side tape in wrapping cloth; an aramid fiber tensile resistant cord is arranged between the primer and the side tape; short fibers are embedded in the primer and the side tape; the wrapping cloth is wide-angle fabric; the special adhesive tape for the novel half-feeding rice harvester uses the aramid fiber cord as a tensile resistant material and increases the impact resistance performance and power transmission of the tape; the transverse short fibers are embedded in the primer so as to increase the lateral stiffness of the tape; the short fibers are embedded in the side tape so as to greatly increase the lateral stiffness of the tape; the wrapping cloth uses wide-angle fabric so as to increase the reverse flexure resistance of the tape.

Owner:锐牛股份有限公司

Moving device of yarn pushing mechanism and adjusting method

ActiveCN114855350AImprove reliabilityStable structureWarp knittingTextile disintegration and recoveryControl engineeringSprocket

The invention discloses a motion device of a yarn pushing mechanism, which comprises a driving input shaft, the driving input shaft is in key connection with a driving chain wheel, the driving chain wheel is in meshed connection with a driven chain wheel through a chain, the driven chain wheel is in key connection with a driven input shaft, the driven input shaft is provided with a guide rail frame, and the driven input shaft penetrates through the guide rail frame and is rotationally connected with a driving shaft; one end of the driving shaft is rotationally connected with a first yarn pushing rod through a first pin shaft, the bottom end of the first yarn pushing rod is rotationally connected with a second pin shaft, the second pin shaft is rotationally connected with a sliding block, the sliding block is fixedly connected with a second yarn pushing rod through a pin shaft, the driving chain wheel is installed on a main shaft of the warp knitting machine, and the driven chain wheel is directly connected with the yarn pushing part. Power is directly transmitted to the input shaft of the yarn pushing part from the main shaft of the warp knitting machine through the driving chain wheel and the driven chain wheel, and compared with an existing plane multi-connecting-rod mechanism, the structure for transmitting the power is simple in structural composition, small in number of needed parts, reliable in work, small in loss, high in efficiency, large in transmission power and high in overload capacity.

Owner:丹阳市益讯机械有限公司

Multi-disk high-power moment-limiting permanent magnet eddy current coupling

ActiveCN106452007BAvoid collisionAvoid wear and tearDynamo-electric gearsElectrical conductorElectric machine

The invention belongs to the field of mechanical transmission. In order to use the shaft coupling to limit a transmission torque of a motor and a transmission system, to protect transmission components from shock overload and to ensure the normal operation of a host machine, a multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling is thus provided. The multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling comprises an input shaft sleeve, a transition connection disc, a left auxiliary casing, a spline sleeve, an output spline shaft, etc. Several magnet plates and conductor plates which are alternately stacked are arranged in the spline sleeve. Each of the magnet discs is circumferentially embedded with an even-number of permanent magnets in which N and S poles are alternately arranged. Permanent magnets of the adjacent magnet discs are axially opposed, and magnetic poles of the adjacent magnet discs are opposite. Inner rings of the two adjacent surfaces of each two adjacent conductor disc and magnet disc are provided with a plurality of small magnets axially opposed and having the same magnetic poles, so that the magnet plate and the conductor plate are not in contact due to the repulsive force. The multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling of the invention employs a multi-disc type structure, so that the permanent-magnetic driving power can be raised without increase in the radial structural dimension of a permanent magnetism transmission device. The multi-disc type large power limited-moment type permanent-magnetism eddy current shaft coupling can be widely applied to occasions where the radial space is limited and the axial direction space is large.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com