Main drive gearbox of twin-screw extrusion machine

A technology of twin-screw extrusion and gearbox, applied in the direction of belts/chains/gears, mechanical equipment, transmission parts, etc., can solve problems such as low efficiency and application limitations, improve bearing life, solve basic space problems, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

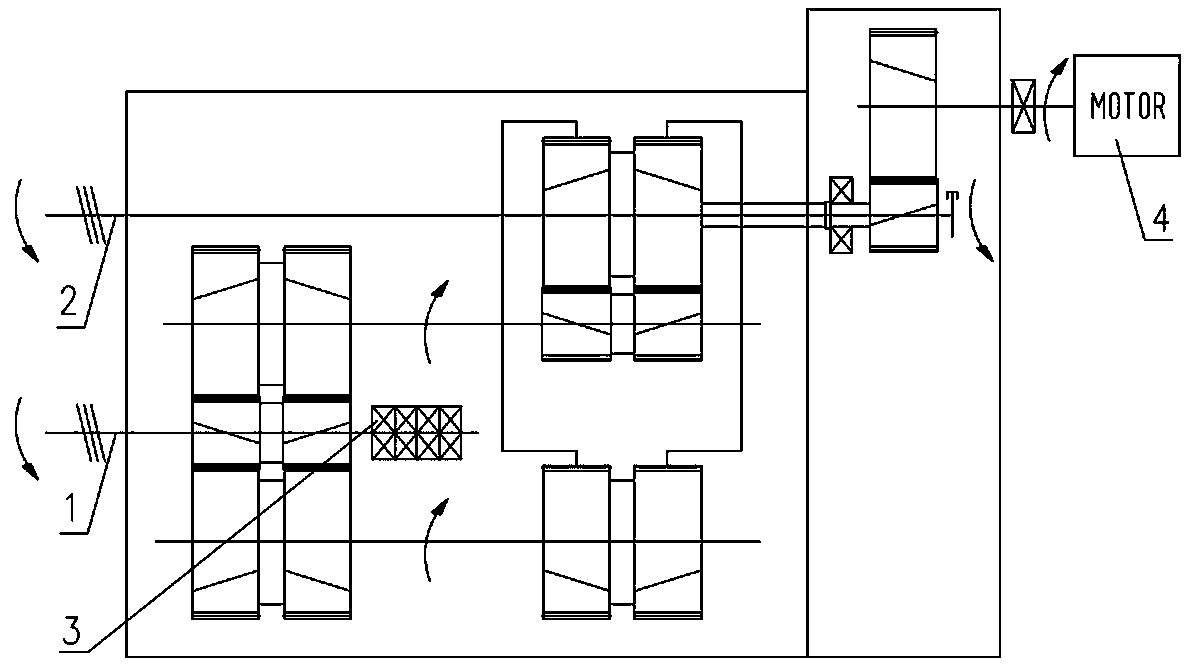

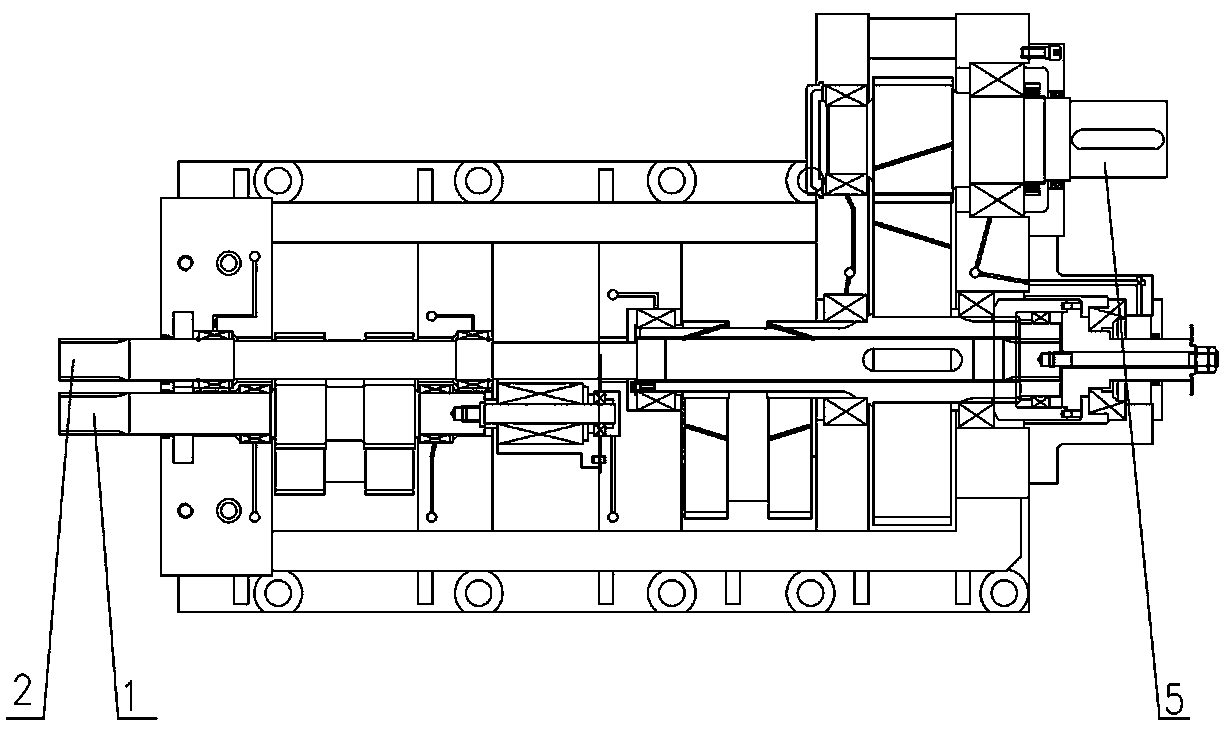

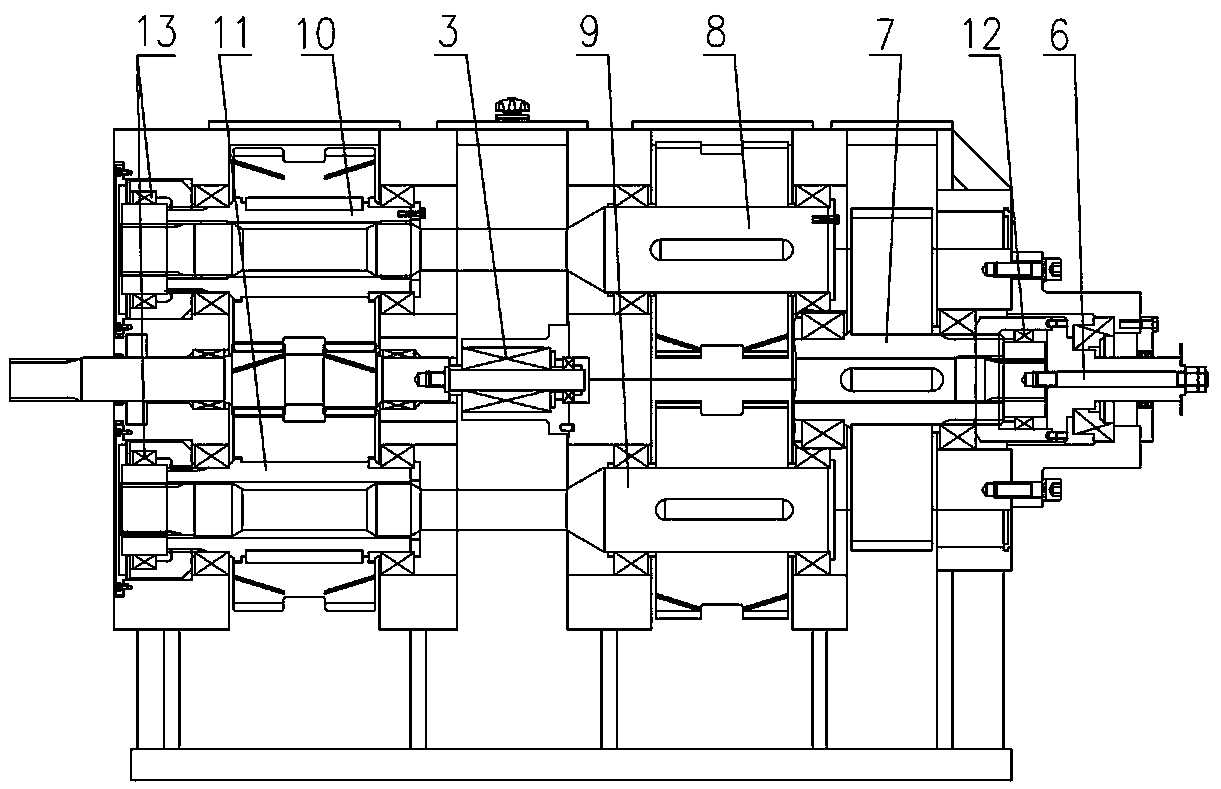

[0026] A main drive gearbox for a twin-screw extruder, the extruder includes an electrically connected gearbox and a motor 4, the gearbox adopts a transmission form in which a herringbone gear pair first splits and then merges, and the gearbox includes a second An output shaft 1, a second output shaft 2, a tandem bearing 3, an input shaft 5, a tie rod 6, a second shaft system 7, a third shaft system 8, a fourth shaft system 9, a fifth shaft system 10, and a sixth shaft system 11. The first tension sleeve adjustment mechanism 12, the second tension sleeve adjustment mechanism 13;

[0027] The input shaft 5 and the pull rod 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com