Movable teeth quasi-stepless speed change device

A continuously variable speed, movable tooth technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high transmission power of gear transmission, inability to achieve stepless speed change, low mechanical efficiency, etc., and achieve transmission power. and improved torque and mechanical efficiency, compact structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

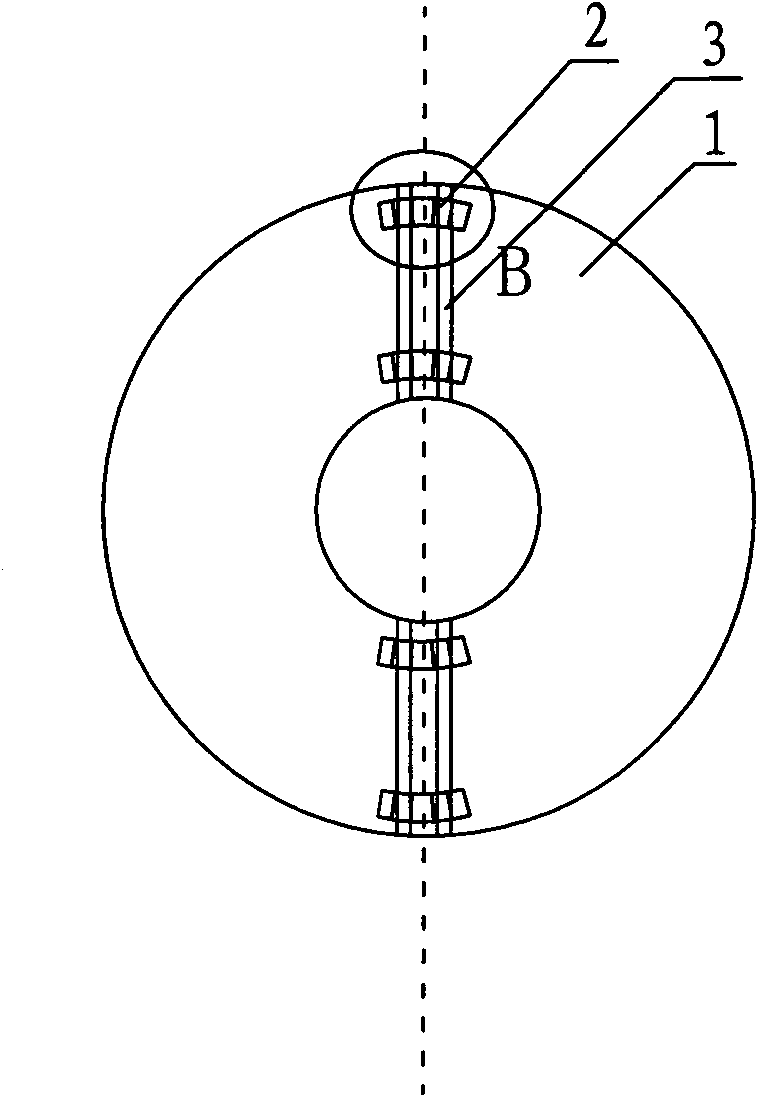

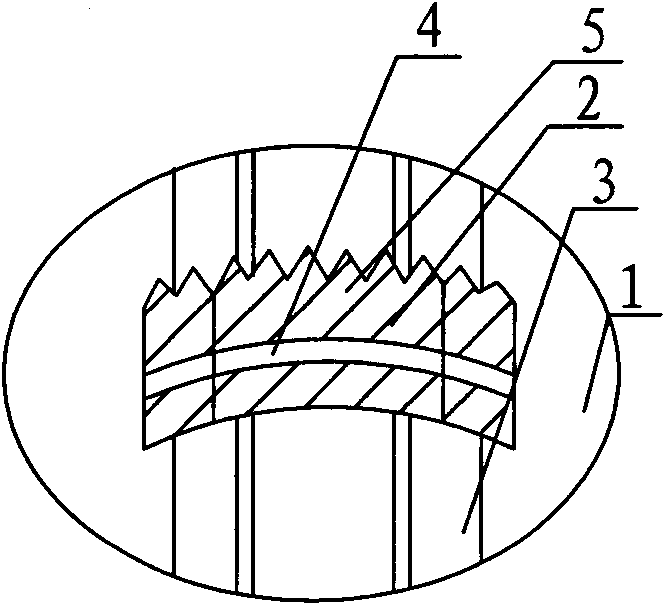

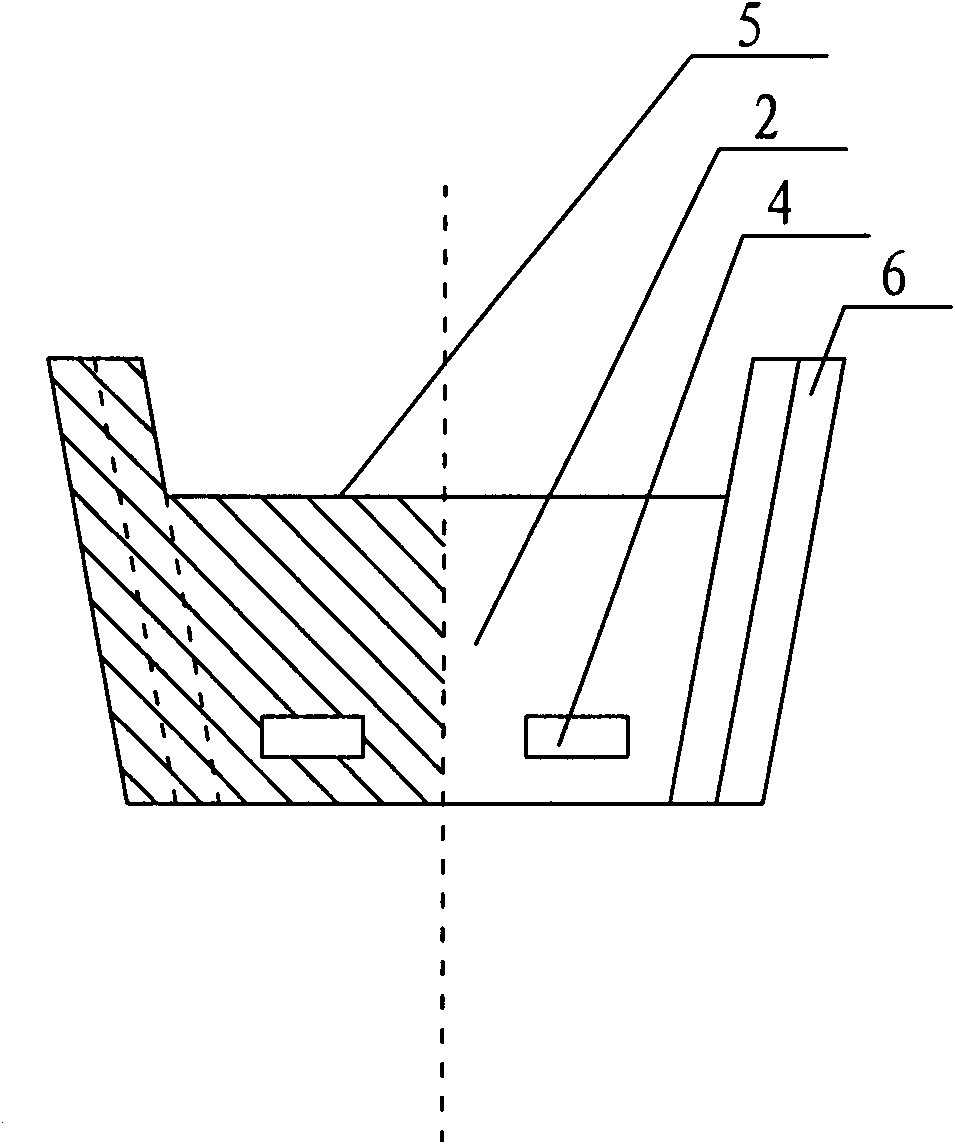

[0026] The driving shaft and the driven shaft are equipped with a flat disk fixed on the shaft and a cone disk that can slide on the shaft. The middle groove of the flat disk and the cone disk is a dovetail groove, and the four straight grooves on both sides are straight grooves. There is a certain change in the included angle, so that each movable tooth body constituting the movable tooth seat slides with equal radius. The first type of movable gear seat is used, and the symmetrical two movable tooth seats are clamped between the flat plate and the cone plate, and the chain guide plate is used to make the wrapping angle of the metal belt greater than or equal to 180 degrees. There are teeth equal to the number of friction plates on the inner side of the metal belt. . A scissor-type equal arm lever is used for speed regulation, and the two cones are respectively pressed with the same spring, and oil pressure can also be used instead of the spring. Use photoelectric or electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com