Intelligent concrete vibrating and plastering integrated equipment based on vibration wave signal control

A signal control and concrete technology, applied in roads, buildings, laying tracks, etc., can solve problems such as slow construction progress, extensive management, interference, etc., and achieve the effects of large power transmission dissipation, increased transmission power, and reduced transmission dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

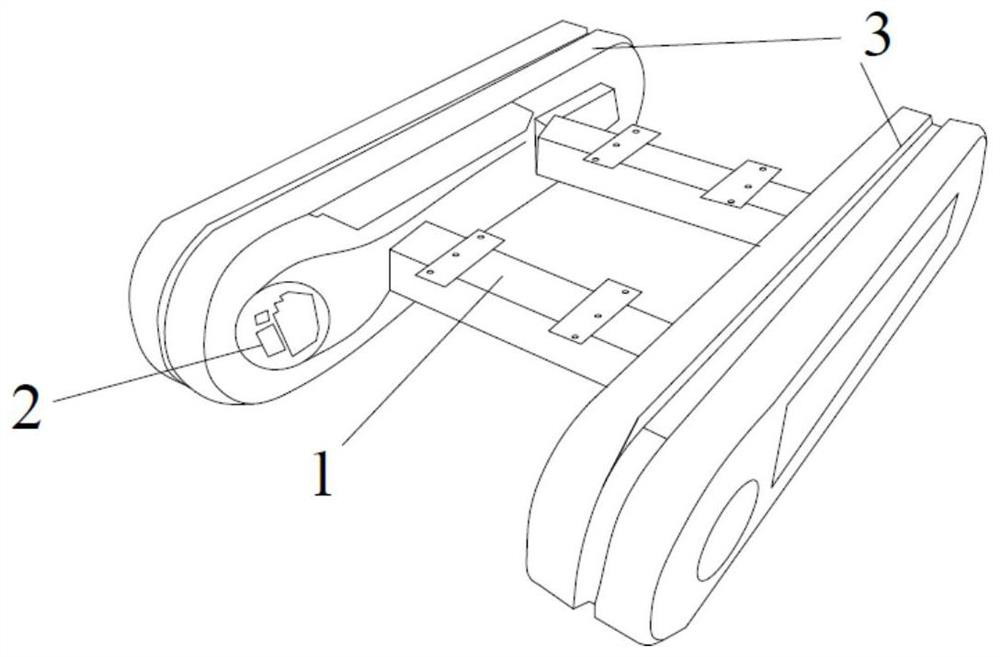

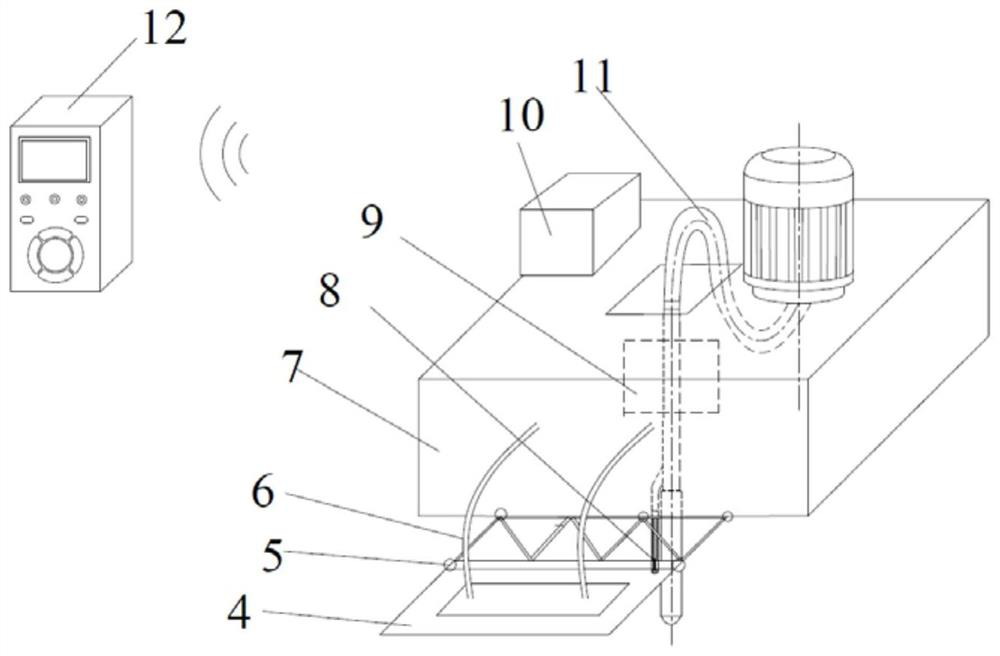

[0021] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings. Take the construction of CRTSIII type ballastless track base plate as an example to explain in detail. CRTSIII type ballastless track base plate is 2900mm wide and 190mm high, with steel mesh inside. The key parameters of the selected machine are shown in Table 1, and the concrete mix ratio and its working performance are shown in Table 2.

[0022] Table 1 Parameters of the integrated machine for intelligent vibrating and plastering

Table 2 Concrete mix ratio and its working performance

A concrete intelligent vibrating and plastering surface integrated equipment based on vibration wave signal control, and its working steps:

(1) According to the structural width a=2900mm, 5 groups of intelligent vibrating and plastering integrated machines (hereinafter referred to as machines) are placed on the pour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com