Wedge squeeze soft start device based on magnetorheological fluid and shape memory alloy

A technology of magnetorheological fluid and memory alloy, which is applied in the direction of transmission, friction transmission, belt/chain/gear, etc. It can solve the problems of performance degradation, low yield stress of magnetorheological fluid, and inability to meet the transmission of high-power power. , to achieve the effect of improving transmission power and reliable transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

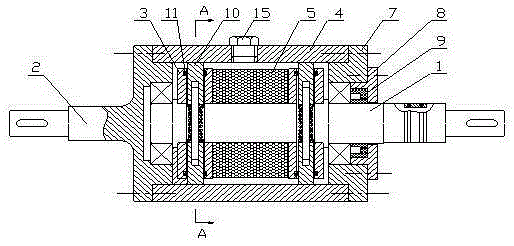

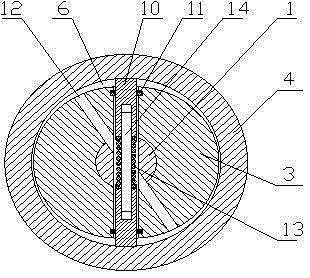

[0021] see figure 1 , a wedge extrusion soft start device based on magnetorheological fluid and shape memory alloy, including a driving shaft 1 and a driven shaft 2, the driving shaft 1 is provided with a device capable of transmitting the torque output by the driving shaft 1 to the driven shaft 2, the magnetorheological fluid transmission mechanism, the magnetorheological fluid transmission mechanism includes two active inner cylinders 3 sleeved on the drive shaft 1 and capable of rotating with the drive shaft 1, sleeved on the drive shaft 1 and located in the two active inner cylinders The excitation coil 5 between the cylinders 3 and the driven outer cylinder 4 sleeved outside the two active inner cylinders 3 and the excitation coil 5, wherein the diameter of the excitation coil 5 is smaller than the inner diameter of the driven outer cylinder 4, the active A wedge-shaped working gap 6 is formed between the inner cylinder 3 and the driven outer cylinder 4, and the gap betwe...

Embodiment 2

[0025] The active inner cylinder 3 and the drive shaft 1 of this embodiment have perforations corresponding to each other, and the active inner cylinder 3 and the drive shaft 1 have flow guide holes 12 communicating with the perforations; two tops are symmetrically installed in the perforations. Rod 10, an O-ring 11 is arranged between the ejector rod 10 and the perforation, and there are guide grooves corresponding to each other on the two ejector rods 10, and a guide rod 14 is arranged between the two ejector rods 10, and the two ends of the guide rod 14 They are respectively located in the guide grooves of the two push rods 10. When there is relative rotation between the driving inner cylinder 3 and the driven outer cylinder 4, the magneto-rheological fluid in the wedge-shaped working gap 6 is squeezed through the guide hole 12 It flows into the perforation and pushes the two push rods 10 to move so that the push rods 10 engage with the driven outer cylinder 4 .

[0026] Wh...

Embodiment 3

[0028] A spring 13 made of a shape memory alloy is arranged between the two push rods 10 of this embodiment, the spring 13 is sleeved on the guide rod 14, a step is provided at the opening of the guide groove of the two push rods 10, and the spring 13 is sleeved on the guide rod 14. on the guide rod 14, and the two ends of the spring 13 are respectively located on the steps at the openings of the guide grooves of the two push rods 10. When the temperature rises and the transfer performance of the magneto-rheological fluid decreases, the spring 13 will elongate under the effect of heat to help push the ejector rod 10, so that the ejector rod 10 is engaged with the driven outer cylinder 4, thus ensuring the soft start device The transmission power at high temperature makes the transmission performance of the soft starter more reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com