Divided flow type master transmission reduction gear box of hot rolling mill

A reduction gear box and hot rolling mill technology, applied to the driving device for metal rolling mills, metal rolling, metal rolling, etc., can solve the problems of large space and unsatisfactory motor speed, so as to reduce production costs and improve Remote control ability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

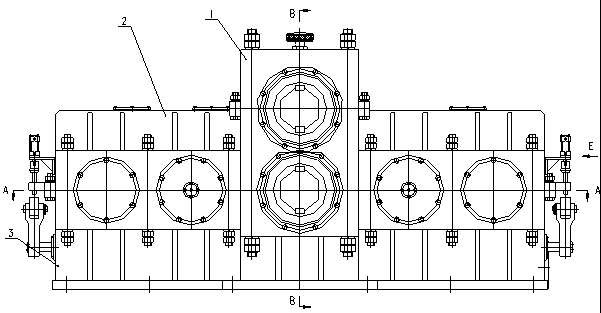

[0023] Depend on figure 1 It can be seen that the box body of this embodiment includes an upper box body 1 , a middle box body 2 and a lower box body 3 , and they are sequentially connected by bolts.

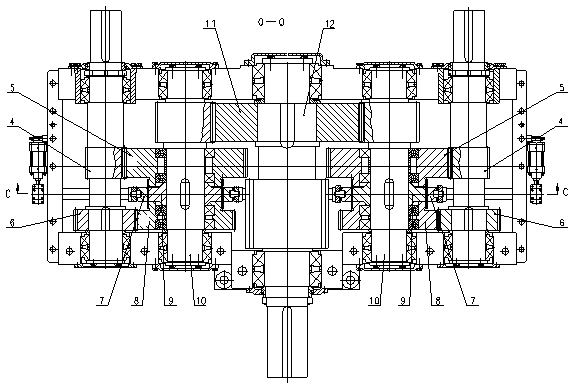

[0024] combined by graph image 3 Figure 4 It can be seen that the output shafts are the long output gear shaft 12 and the short output gear shaft 17, the two independent transmission systems with the same structure and parameters are symmetrically located on both sides of the long output gear shaft 12, the long output gear shaft 12, the short output gear shaft 17 and the independent The shafts in the transmission system are parallel to each other; wherein, the short output gear shaft 17 is supported on the junction of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com