Multi-disk high-power moment-limiting permanent magnet eddy current coupling

A permanent magnet eddy current, high-power technology, applied in electromechanical transmission devices, electromechanical devices, electrical components, etc., can solve the problems of incomplete unloading, inability to use high-power transmission systems, scrapping of couplings, etc., to prevent collisions and wear , Improve the transmission power and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

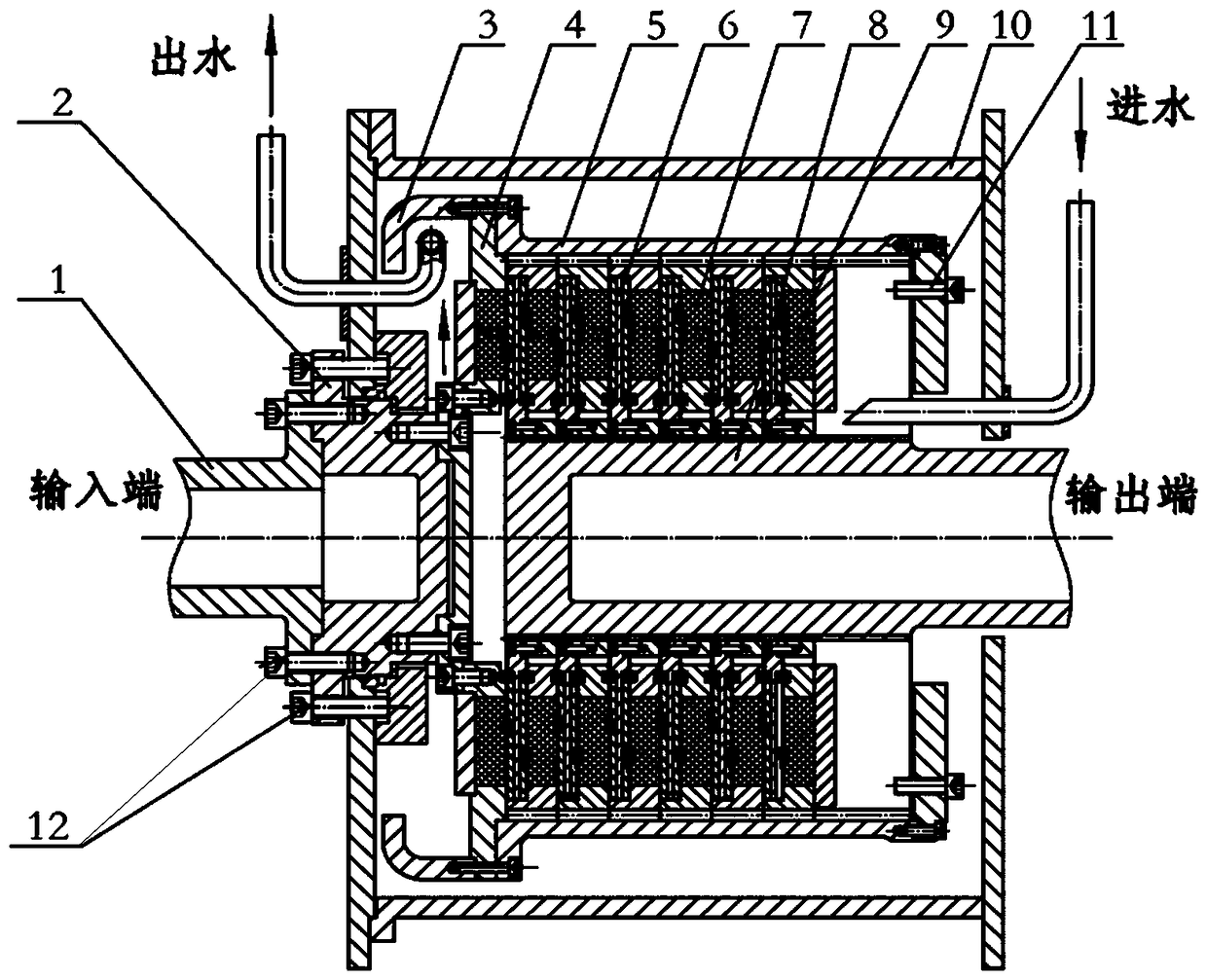

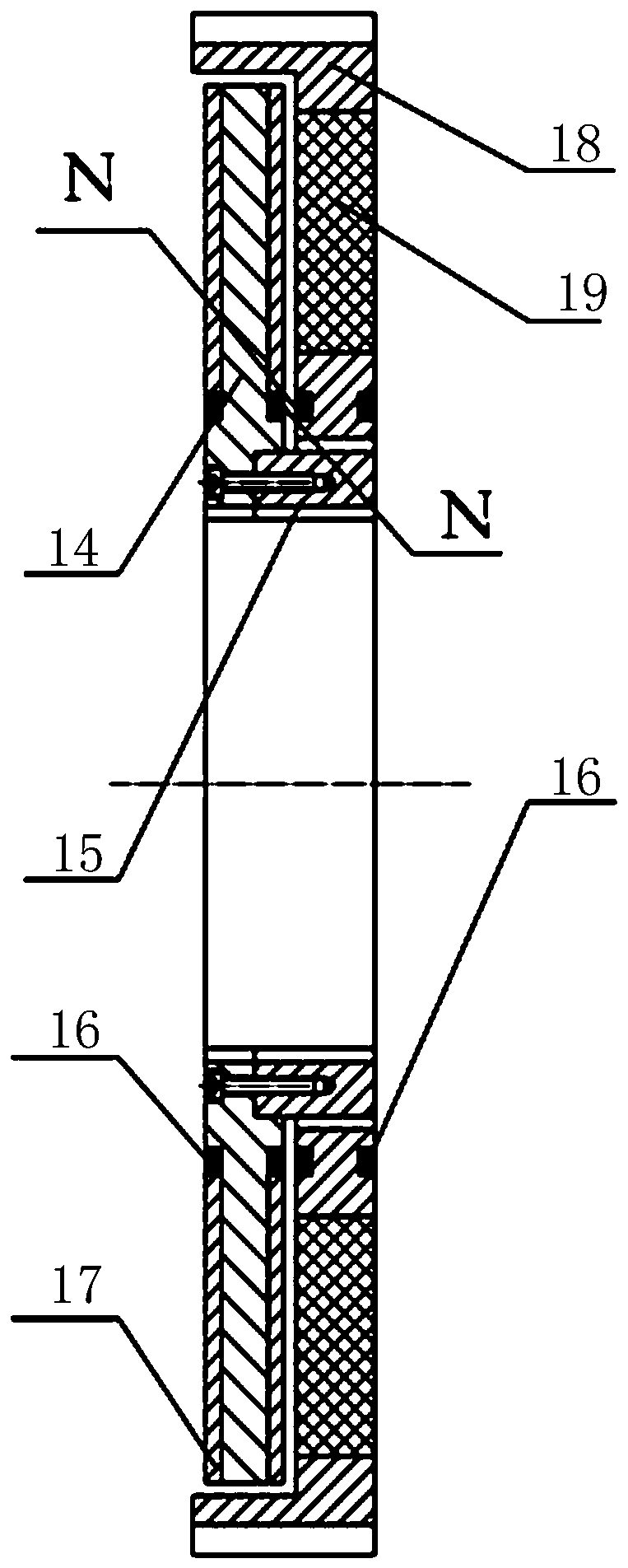

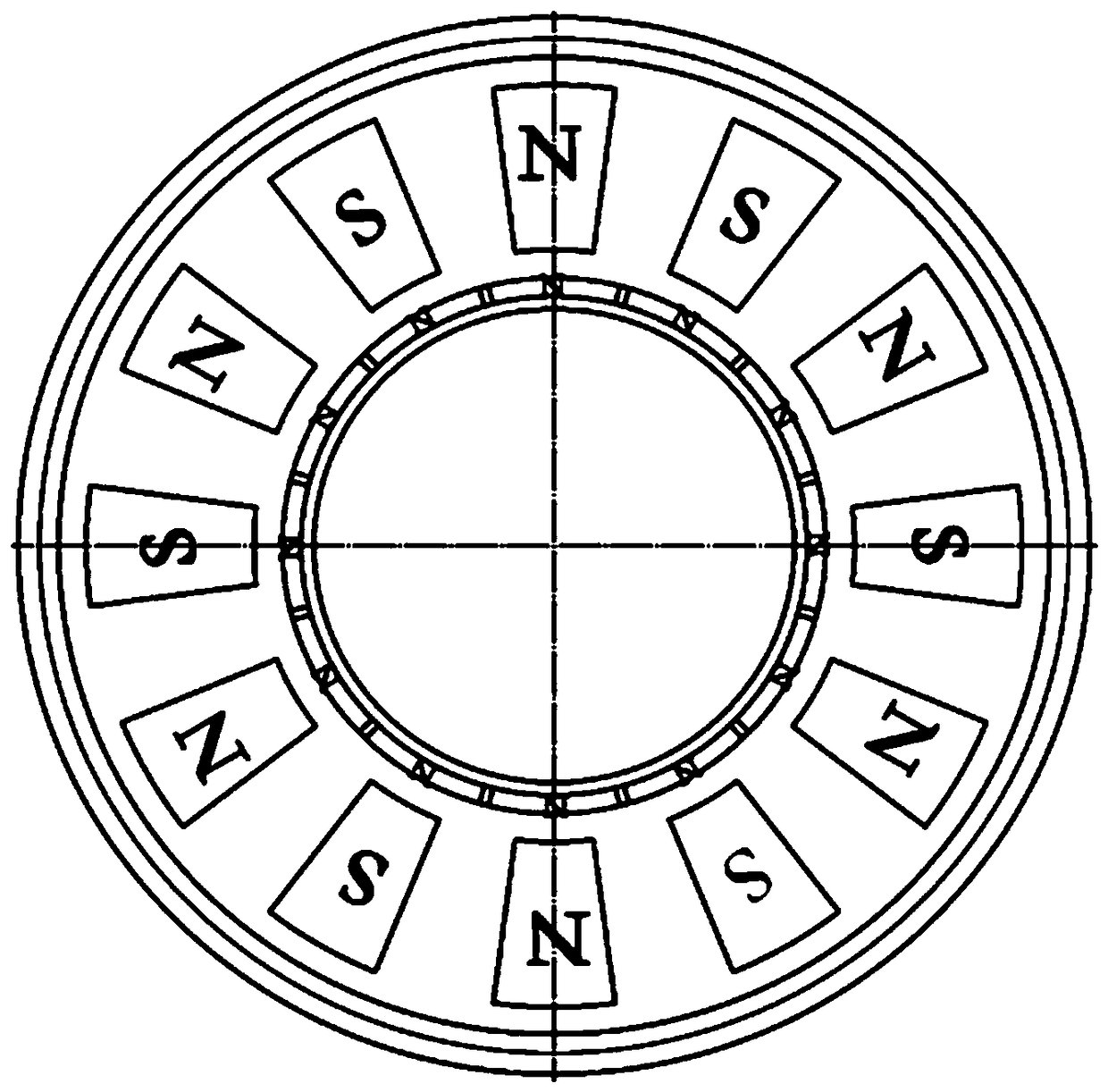

[0047] Such as figure 1 The multi-disk high-power moment-limiting permanent magnet eddy current coupling shown includes input shaft sleeve, transition connection disc, left auxiliary housing, spline sleeve, input side magnet disc, several middle magnet discs, and output side magnet disc , several conductor disks, output spline shafts, axial limit screws, supporting shells, etc., the multi-disc structure is an index of magnet disks and conductor disks stacked alternately to form a multi-disk structure, which can be adjusted according to power requirements Design the number of magnet disks and conductor disks, the active rotor composed of magnet disks, spline sleeves, left auxiliary shells, right end plates, etc. is connected to the motor shaft; the driven rotor composed of conductor disks, output spline shafts, etc. Reducer input shaft connection. Except f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com