Double differential type planetary stepless automatic variable speed gear for vehicle

An automatic transmission device and double differential technology, applied in the field of vehicle transmission, can solve the problems of large number of automatic transmission parts, manufacturing precision and structural complexity, and high production cost, and achieve convenient maintenance and repair. The effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

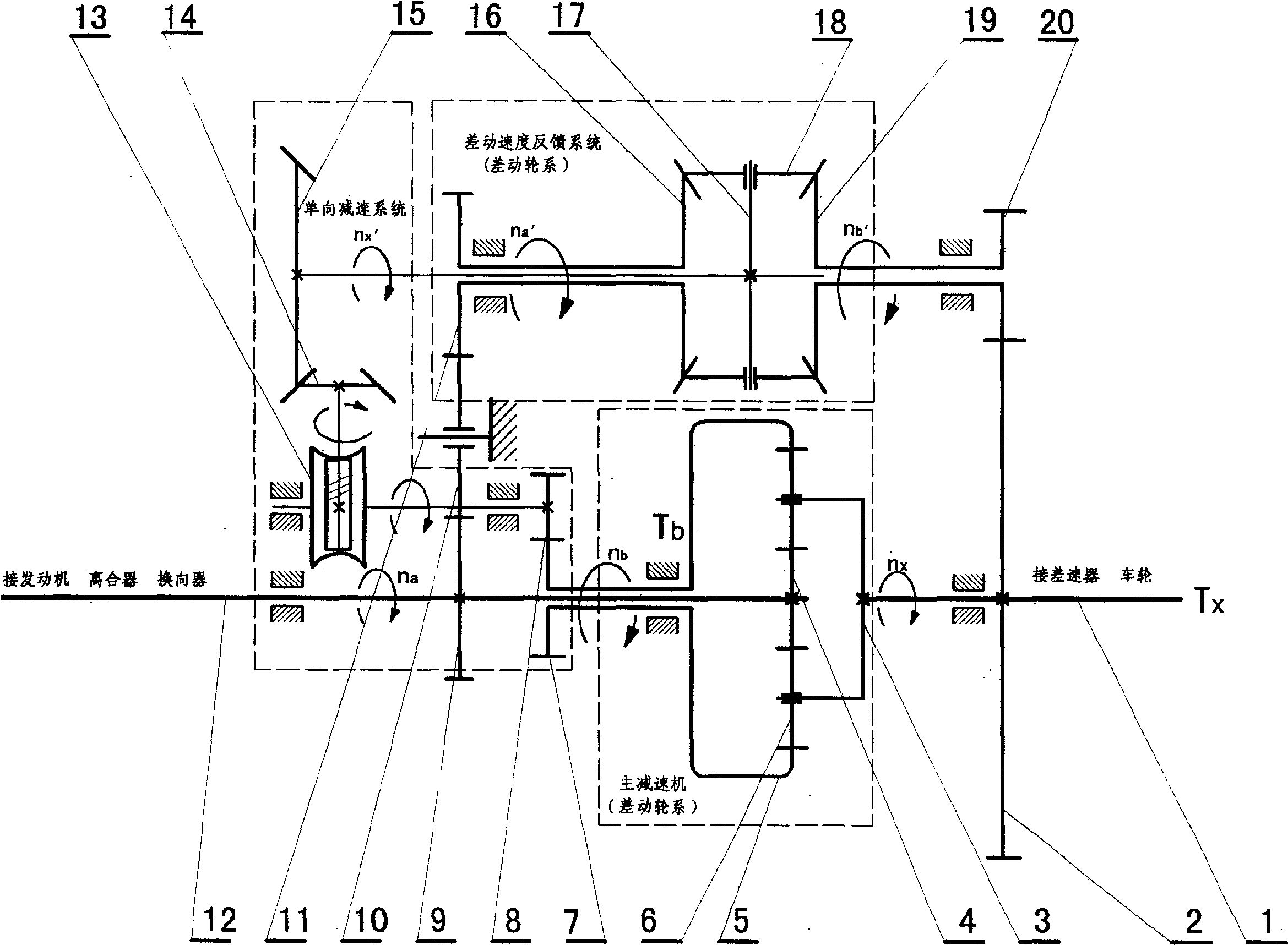

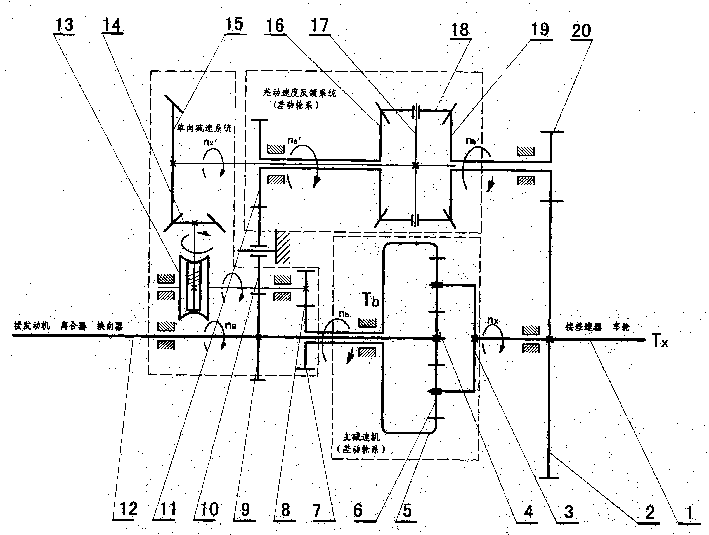

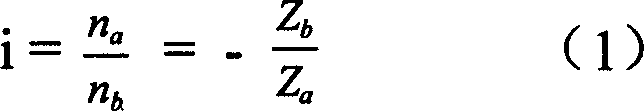

[0012] combined with figure 1 To illustrate the embodiment of the present invention: the vehicle double differential planetary continuously variable automatic transmission adopts two differential planetary gear trains, that is, the main reducer is composed of a differential planetary gear train, and the differential speed feedback The system is composed of another differential planetary gear train, which is connected with a one-way reduction system with one-way transmission characteristics composed of a gear pair and a worm gear pair, and is combined into a double differential planetary stepless automatic transmission device. The sun gear 4, the inner ring gear 5, the planet gear 6 and the planet carrier 3 of the differential planetary gear train of the final reducer are all spur gears, and the sun gear 16 and the inner ring gear of the differential planetary gear train of the differential speed feedback system are all spur gears. Gear 19, planetary wheel 18 and planet carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com