Automatic welding machine for ear straps of face mask

A welding machine and mask technology, applied in clothing, household components, tools for sewing clothes, etc., can solve the problems that the mask body cannot be accurately positioned, the conveyor belt is not rigidly connected, and the structure is not compact enough to facilitate maintenance and debugging. Excellent high-speed performance and increased pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

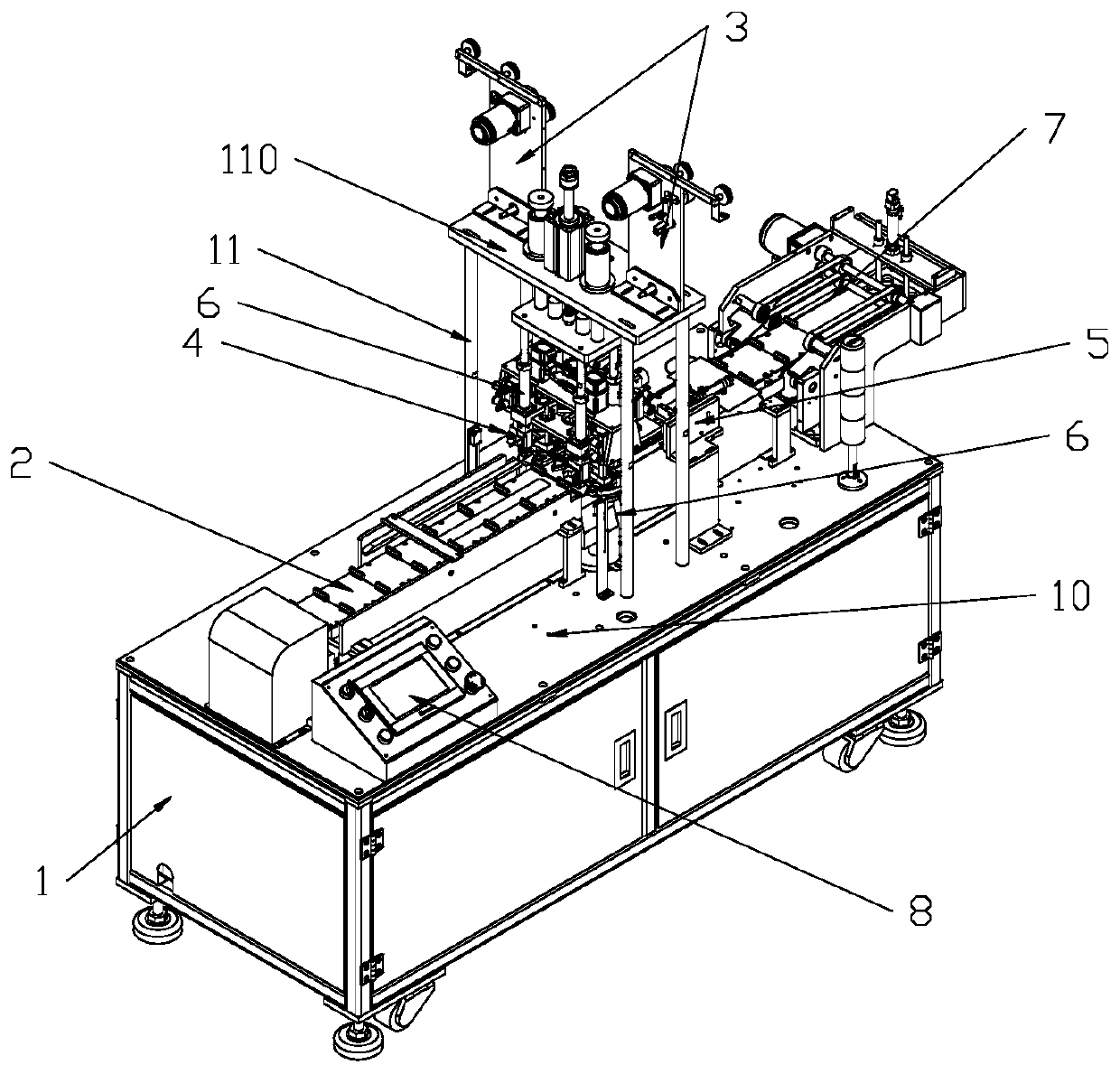

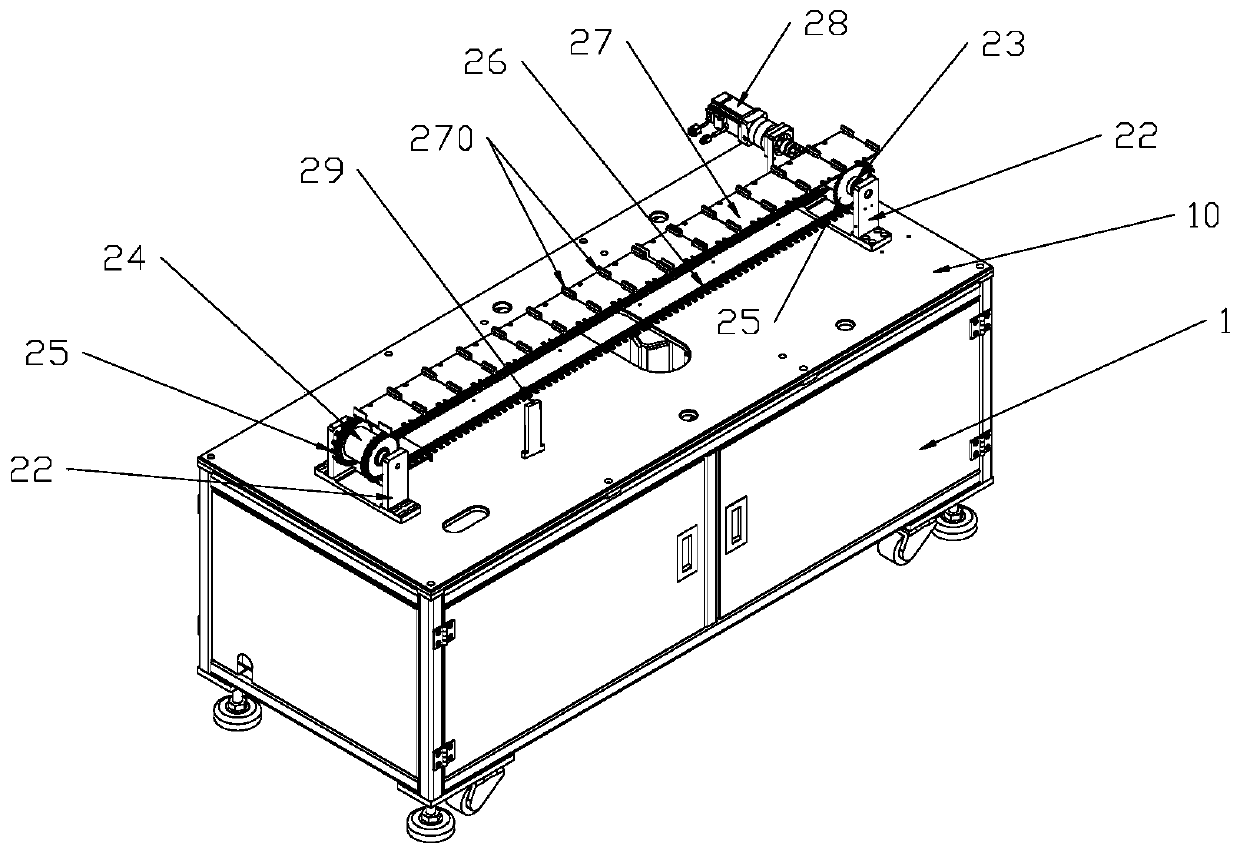

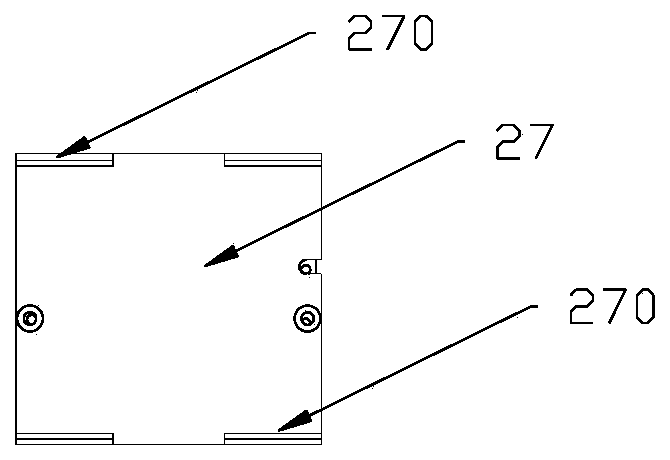

[0035] Such as figure 1 As shown, a kind of mouth mask earband automatic welding machine of the present invention comprises frame 1, and above the frame is equipment platform 10, and equipment platform 10 is provided with mask conveying mechanism 2, wire-feeding mechanism 3, winding mechanism 4, wire cutting mechanism Mechanism 5, welding mechanism 6, palletizing mechanism 7 and controller 8, wire inlet mechanism 3, winding mechanism 4, thread trimming mechanism 5 and welding mechanism 6 are set above the mask conveying mechanism 2, and palletizing mechanism 7 is set on the mask At the output end of the conveying mechanism 2, the controller 8 is used to automatically control the operation of the above-mentioned mechanisms, and at the same time, it can set various operating parameters. The concept of "line" in the above-mentioned thread entry, winding, and thread cutting all refers to the earband line, that is, before the earband is cut, it is a very long earband line.

[0036...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com