Reinforced V belt

An enhanced, tensile body technology, applied in the direction of V-shaped belts, belts/chains/gears, mechanical equipment, etc., can solve the problems of not forming a whole, the belt is easily damaged, and the stress is easy to concentrate, so as to achieve fatigue resistance Improve and improve the stability and reliability of transmission, and avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

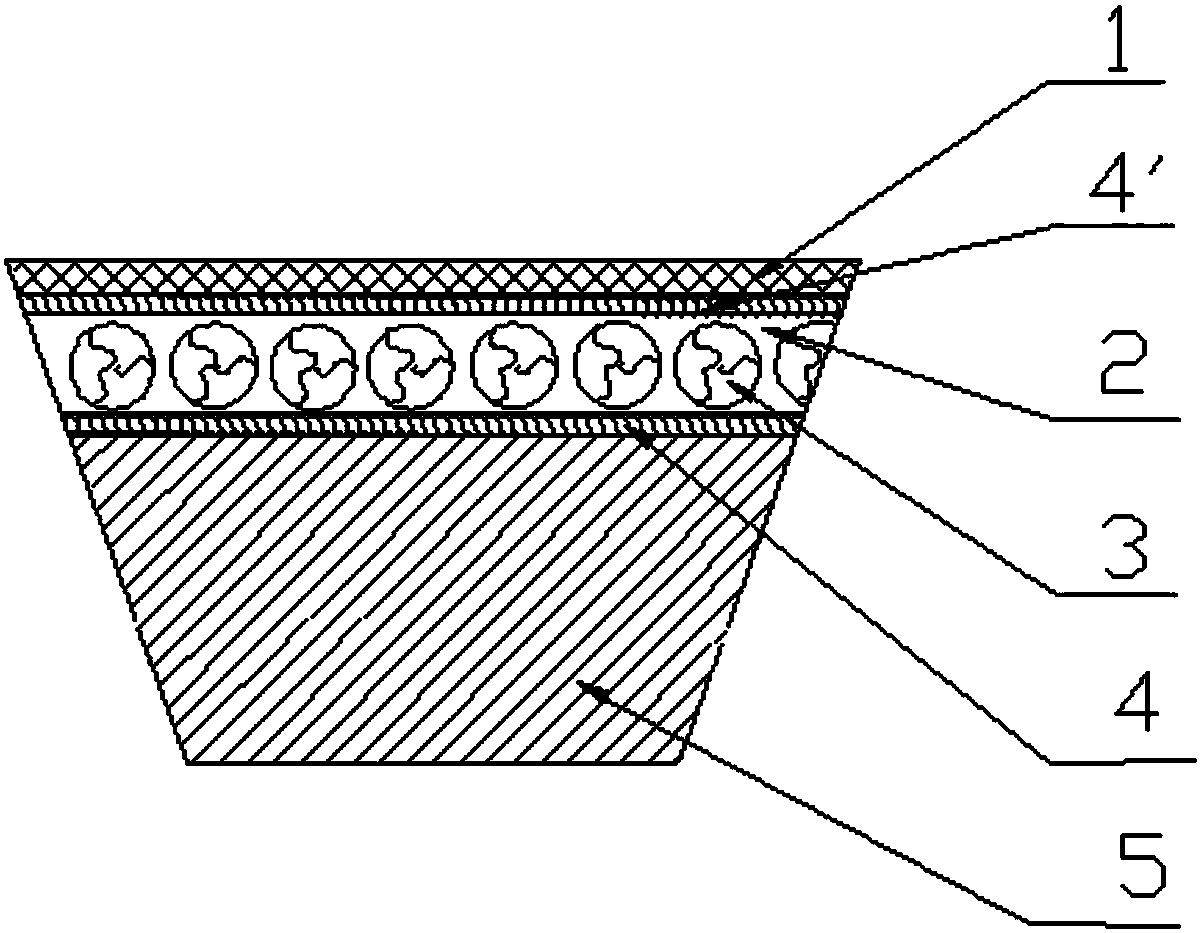

Embodiment 1

[0051] Hardened cord fabric (4, 4'):

[0052] White nylon cord fabric (provided by Pingdingshan Shenma Industrial Co., Ltd.), PA66, specification 1400dtex / 2; diphenylmethane diisocyanate (MDI) (product of Yantai Wanhua) / toluene ratio (parts by weight) is 5 / 95, Activation temperature 200°C, activation time 30s; resorcinol-formaldehyde-latex (RFL): R / F (molar ratio) 1 / 2, RF / EPDM latex (weight ratio of solids) 1 / 4 , RFL concentration 20% (by weight of solids); curing temperature 230 ° C, curing time 35S. The stiffness of the obtained cord fabric is 3.5×10 -3 N / dtex.

[0053] Compression rubber layer (5):

[0054] Contains 100 parts of main rubber EPDM rubber (Arlanxeo product) (parts by weight, the same below), 5 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant RD, 45 parts of carbon black N330, 2280 parts of paraffin oil 10 parts, 20 parts of short fiber, 4.5 parts of cross-linking agent BIPB, and 2 parts of auxiliary cross-linking agent PDM are mixed by...

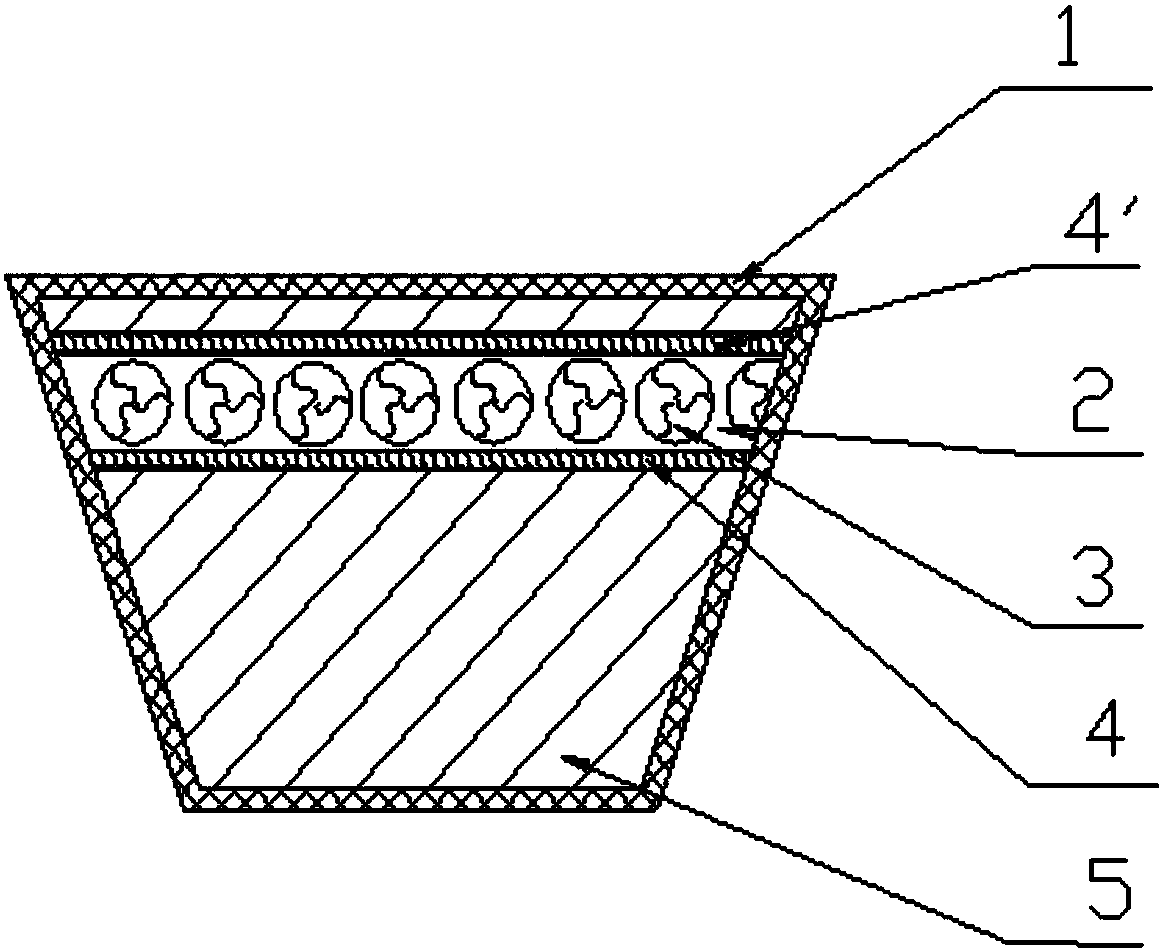

Embodiment 2

[0064] Hardened cord fabric (4, 4'):

[0065] White polyester cord fabric (provided by Wuxi Taiji Industrial Co., Ltd.), PET, specification 1100dtex / 2; diphenylmethane diisocyanate (MDI) (product of Yantai Wanhua) / toluene ratio (parts by weight) 7 / 93, activation temperature 200℃, activation time 35s; curing temperature 235℃, curing time 40s. The stiffness of the obtained cord fabric is 4.7×10 -3 N / dtex.

[0066] Others are the same as embodiment 1.

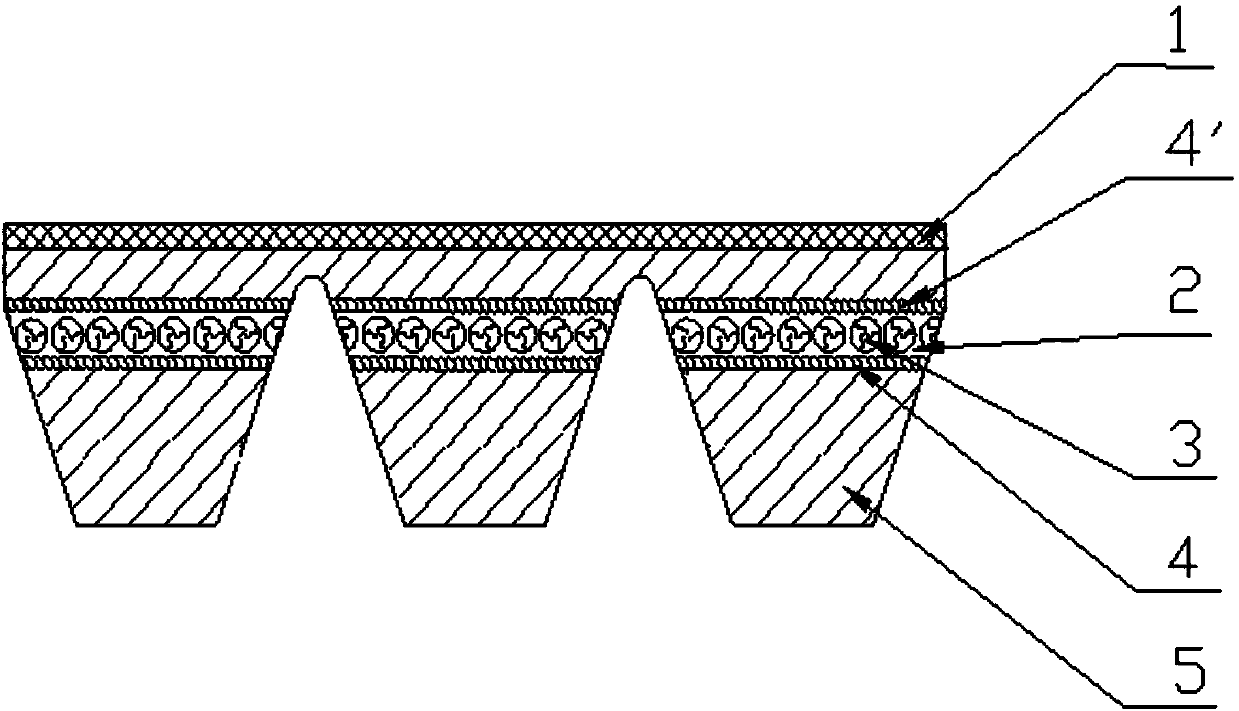

Embodiment 3

[0068] Hardened cord fabric (4, 4'):

[0069] White polyester cord fabric (provided by Wuxi Taiji Industrial Co., Ltd.), PET, specification 1100dtex / 2; diphenylmethane diisocyanate (MDI) (product of Yantai Wanhua) / toluene ratio (parts by weight) 10 / 90, activation temperature 200°C, activation time 35s; curing temperature 235°C, curing time 35s. The stiffness of the obtained cord fabric is 6.2×10 -3 N / dtex.

[0070] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com