Chained oscillating tooth stepless speed change device

A technology of stepless variable speed and movable teeth, which is applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of large normal pressing force, small transmission power, low mechanical efficiency, etc., and achieve transmission Improved power, torque, and mechanical efficiency, extended service life, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

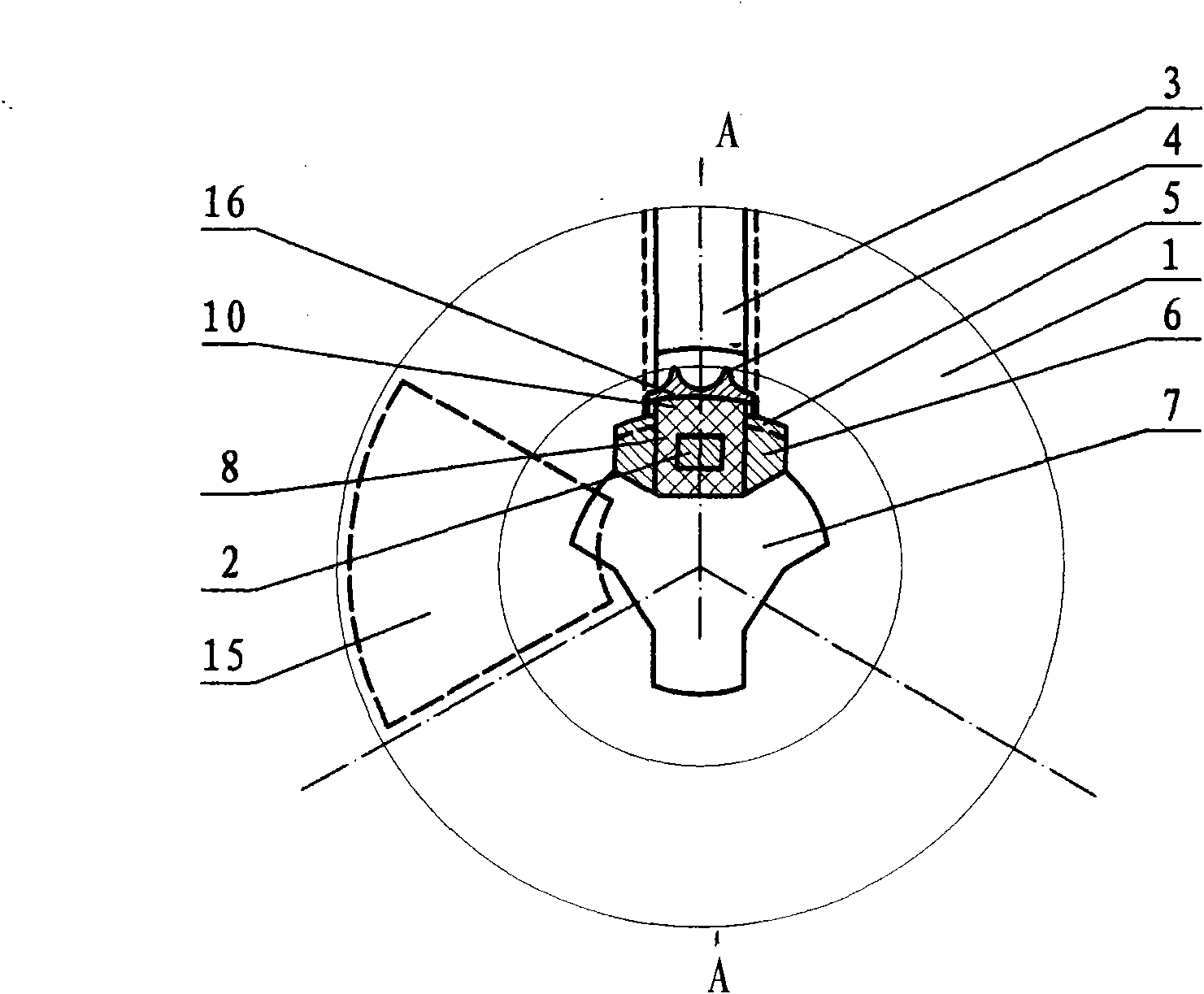

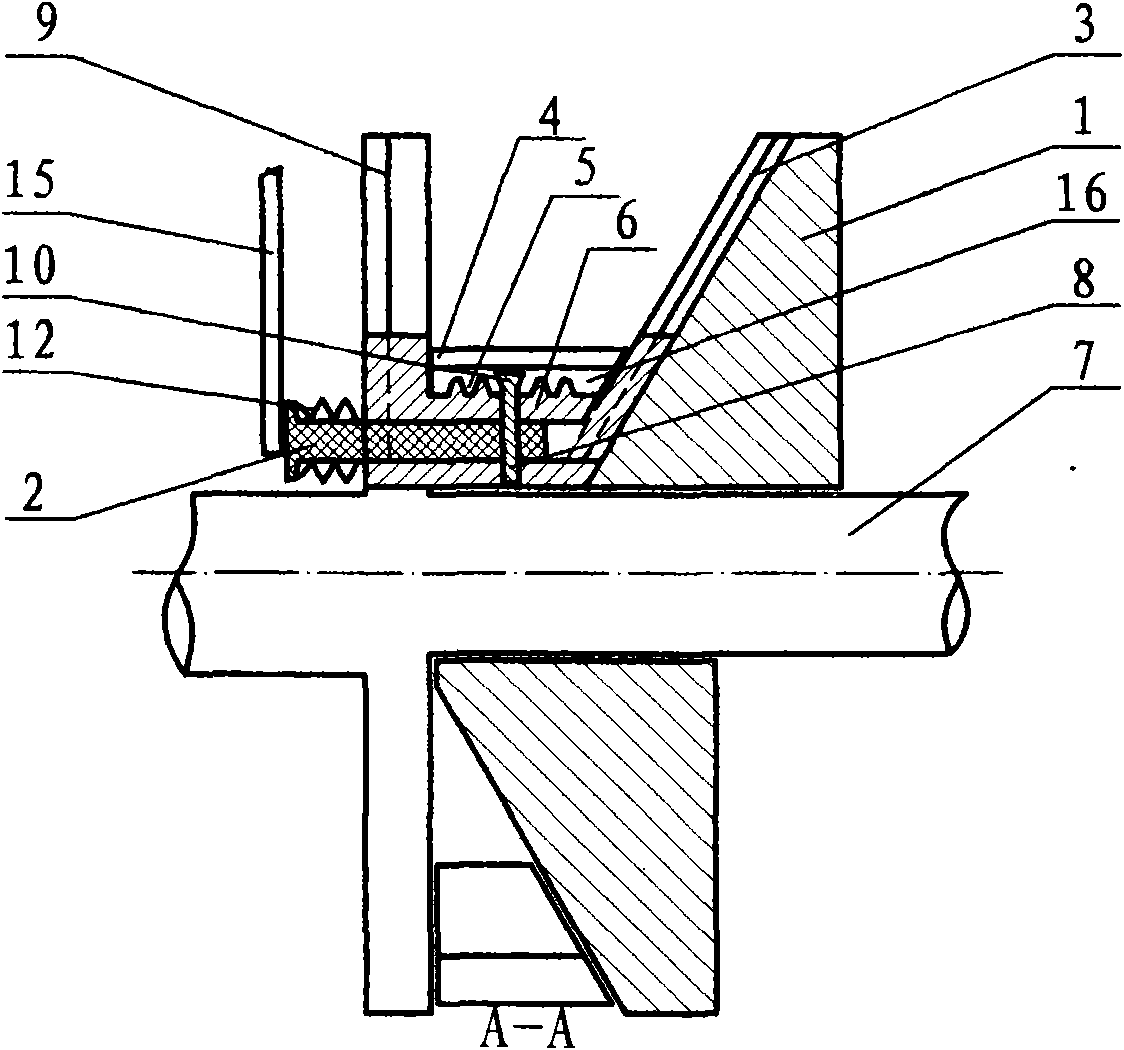

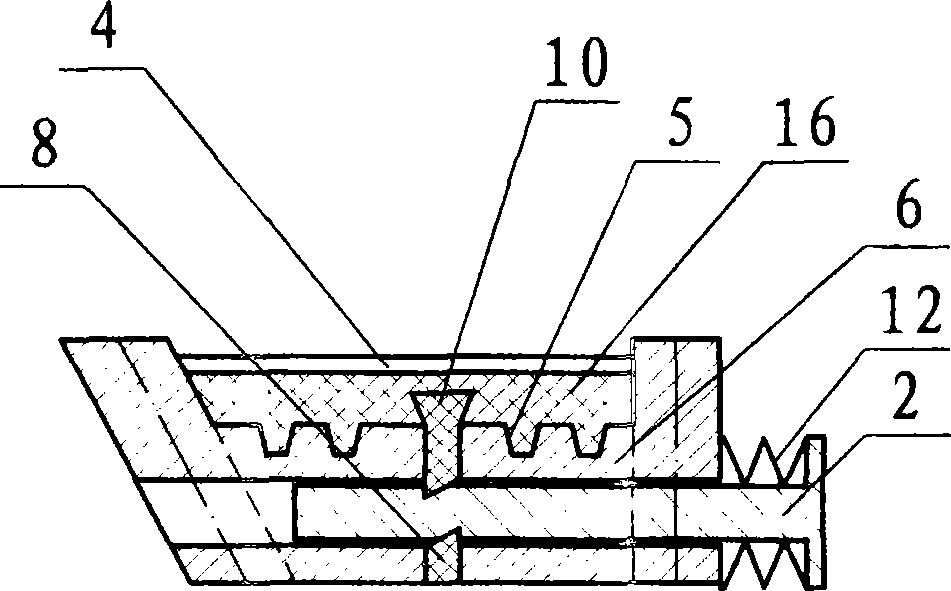

[0021] The driving shaft and the driven shaft are equipped with a flat plate fixed on the shaft and a cone plate that can slide on the shaft. There are 3 sets of radial dovetail grooves equally divided on the plate and the cone plate. The first type of movable gear seat is used. The equally divided movable tooth seat is clamped between the flat disk and the cone disk, and the chain guide plate is used to make the wrapping angle of the metal chain greater than or equal to 180 degrees. There are arc teeth on the inner side of the metal chain, which mesh with the two teeth on the movable tooth body , the cone on the passive shaft is pressed by a disc spring, and the cone on the driving shaft uses the rotation between the screw and the nut to compress or separate the moving cone. In a free state, the ejector rod is tensioned by a disc spring, so that The movable tooth body and the movable tooth seat are tightly combined by friction on the wedge groove surface. When changing speed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com