Stepless variable drive of stepless transmission

A continuously variable transmission, continuously variable speed technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of easy wear and tear of transmission belt or transmission chain, sluggish transmission of power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

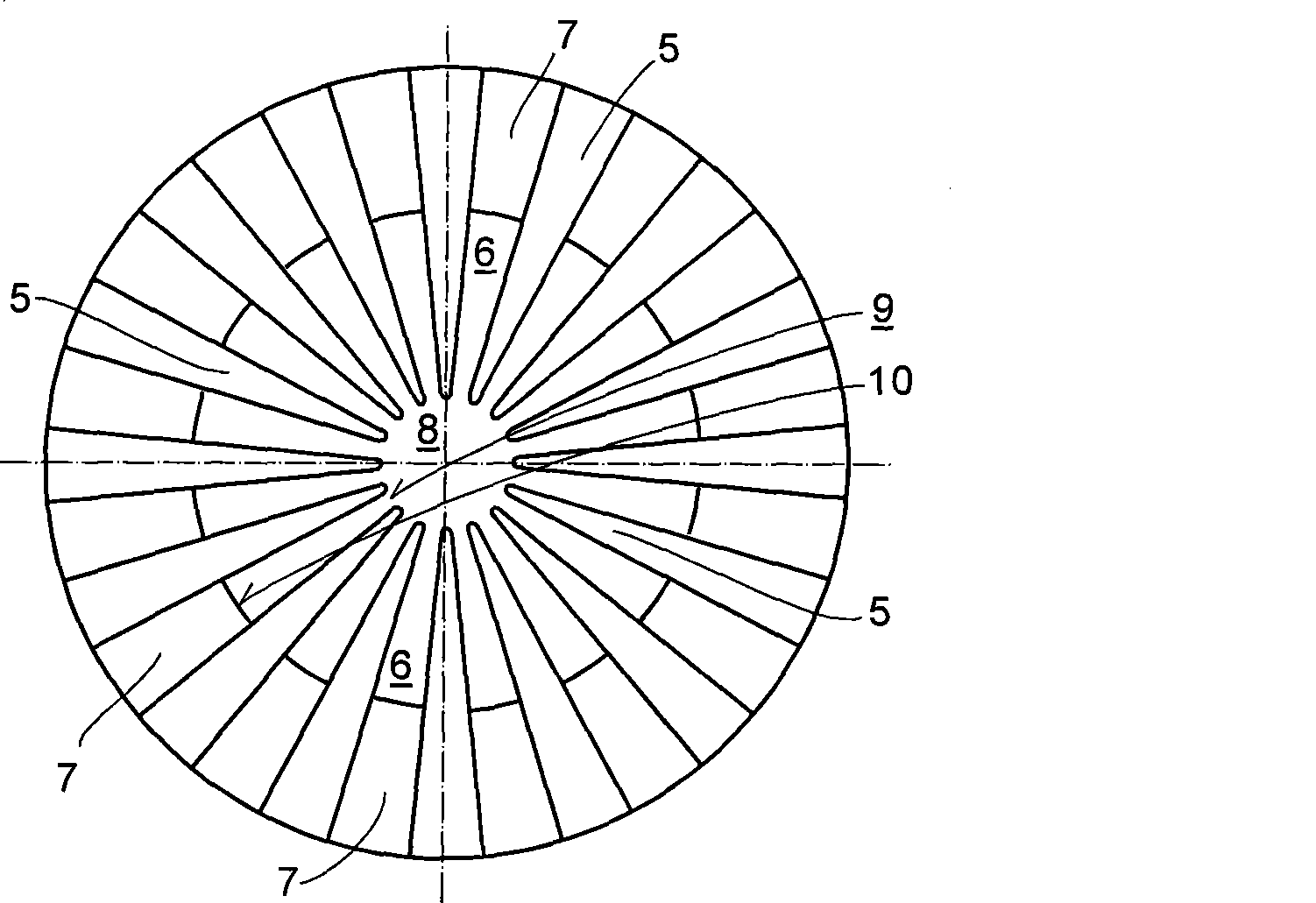

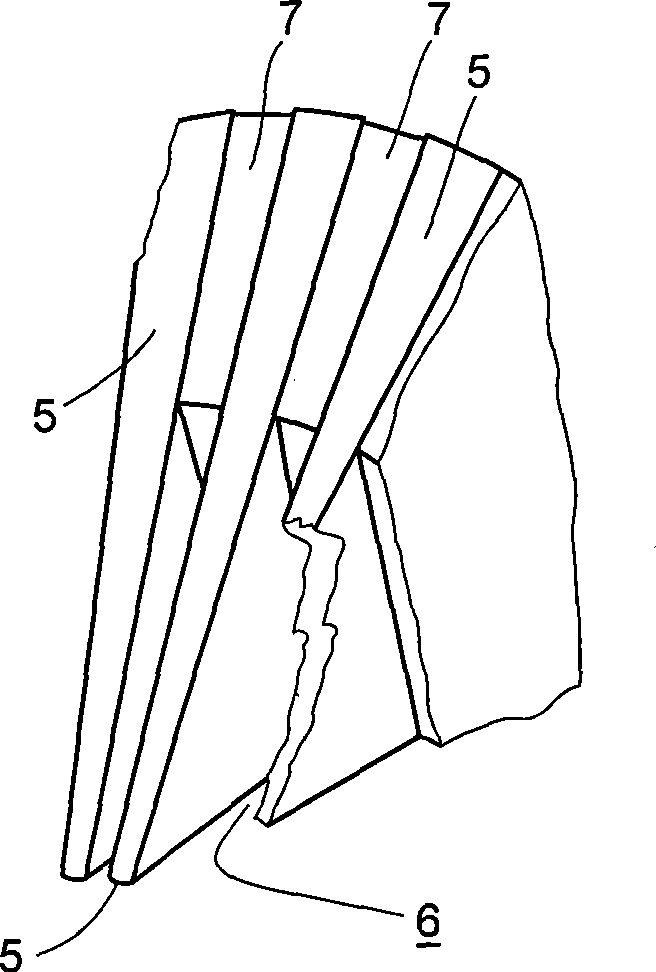

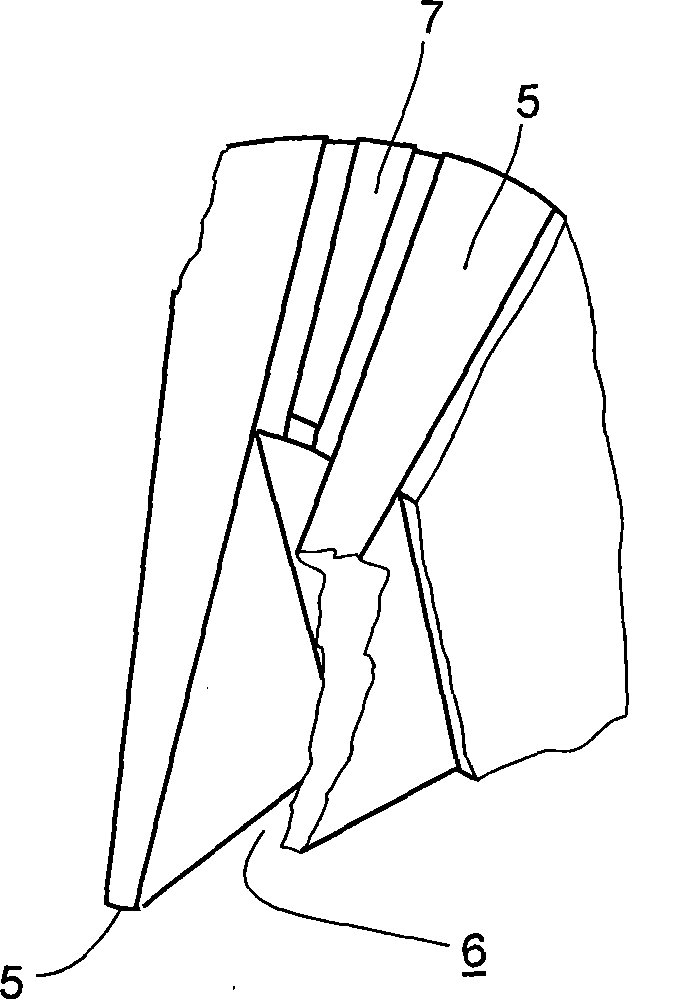

[0040] Implementation mode one: figure 1 Shown is the front view of the cone disc. It can be seen from the figure that fan-shaped grooves 6 and fan-shaped spokes 5 are arranged alternately on the front of the cone disc, and the inner narrow end 9 of the fan-shaped groove 6 communicates with the shaft hole 8. In this figure, the area 7 extending from the outer wide end 10 of the fan-shaped groove 6 to the large end of the cone disk is a plane with its four corners as the base point. figure 2 Then the appearance of the area 7 is displayed more intuitively. The area 7 adopts such a plane, so that the transmission belt and its outer hoop chain can smoothly move outward when the pulley expands the transmission radius. If the area 7 has a large circumferential span, a radial ridge block with an inner slope can also be retained in the middle, such as image 3 As shown, ridged blocks increase the circularity of the cone disc. Figure 4 , Figure 5 What is shown is that the two cone disc...

Embodiment approach 2

[0042] Implementation mode two: such as Figure 18 with Figure 20 As shown, the two edges of the fan-shaped spokes 5 on the front face of the cone have a chamfered surface 19 that is closer to the larger end of the cone and forms a chamfered surface 19, and at the same time, each layer of the steel ring belt 13 and each layer of the transmission belt 12 are loose The steel endless belt 13' is provided with elongated holes 20 on both sides of the plane, and an outer hoop chain 14 narrower than the corresponding position of the V-shaped ring groove of the transmission pulley is adopted. When working, the steel endless belt 13 and the loose steel endless belt 13' of the transmission belt 12 are crushed by the elongated holes 21 at the pressing position of the fan-shaped spokes 5, and the steel endless belt 13 and the loose steel endless belt 13' are compressed. Correspondingly, there is a slight indentation, forming the friction between the fan-shaped spokes 5 and the transmission b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com