High-power stepless transmission

A continuously variable transmission, high-power technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problem of not being able to meet the high-speed and high-power transmission of power, the tangent point between the tooth chain and the rotation plane is not fixed, and has not been effectively obtained. Solve problems such as to achieve the effect of improving transmission power, improving work reliability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

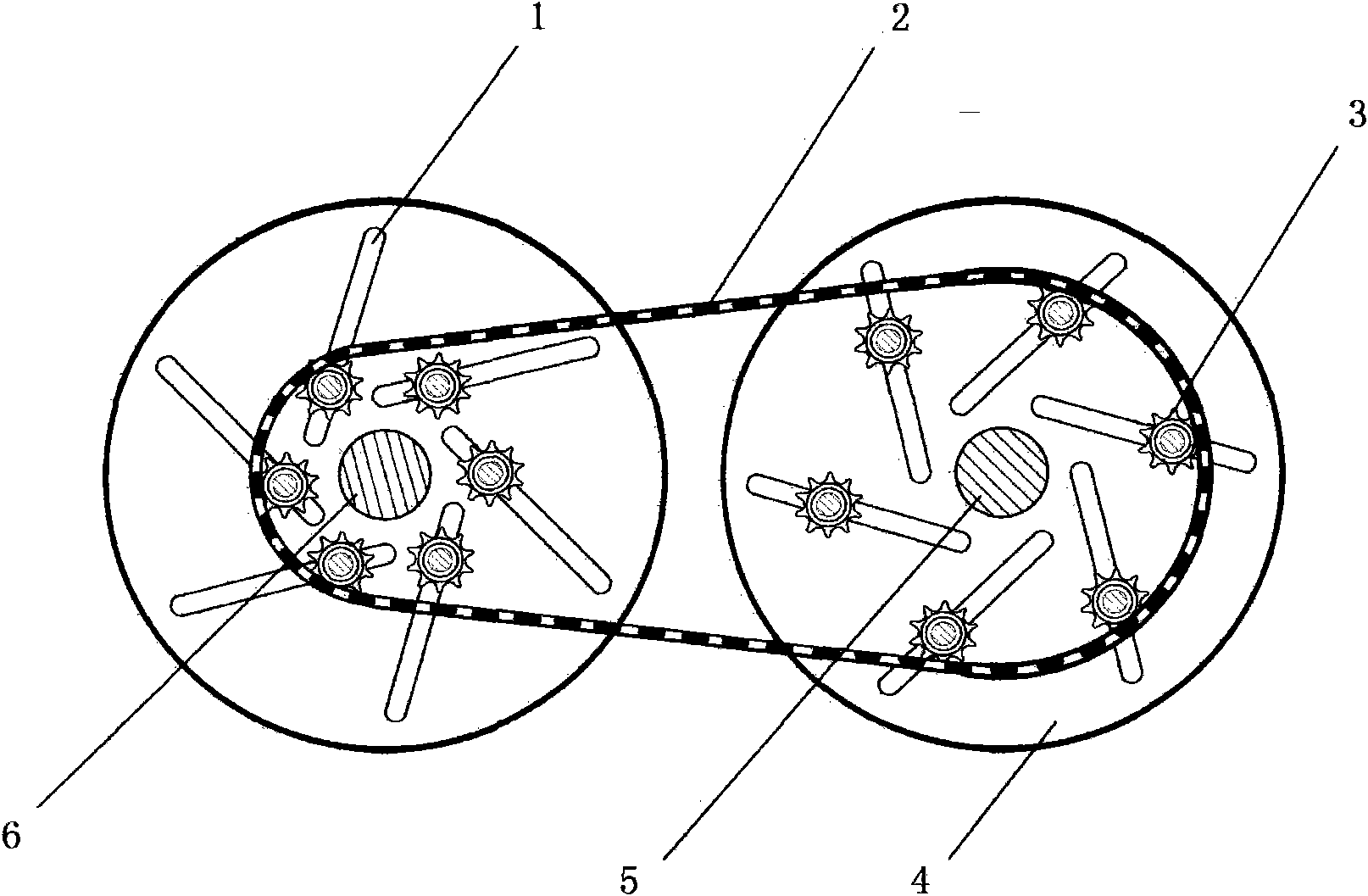

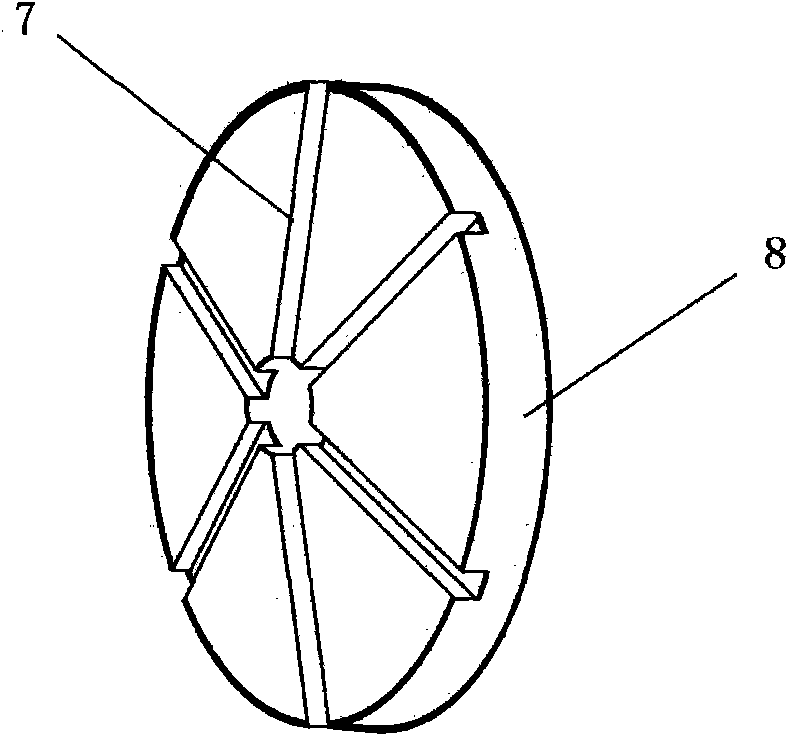

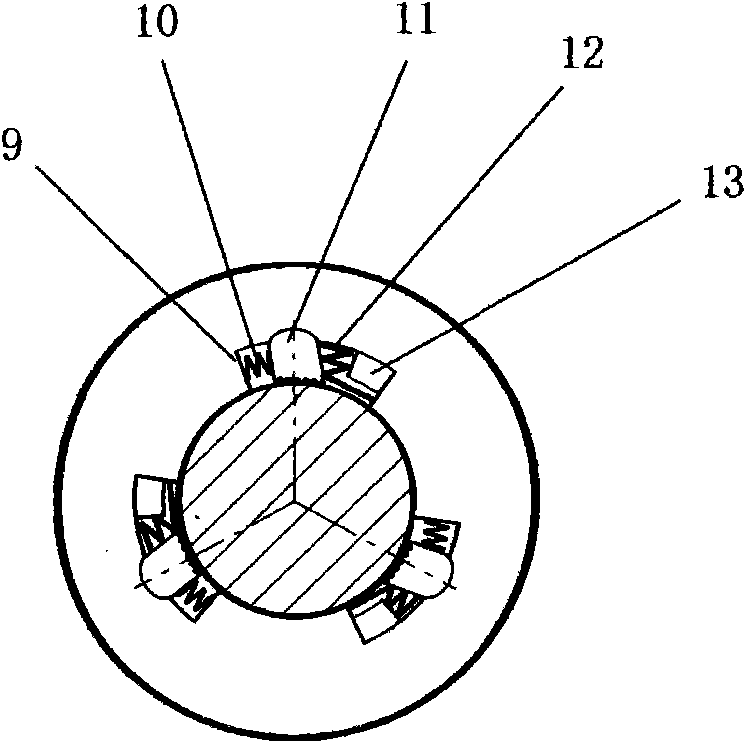

[0027] See figure 1 with figure 2 , the driving drive shaft (5) and the driven drive shaft (6) are equipped with a speed regulating disc (4) and a driving wheel (8), the driving wheel is located at the back of the speed regulating disc, and the shaft of the planetary gear (3) passes through The oblique slot hole (1) on the speed control disc is located in the radial chute (7) of the drive wheel, and the tooth chain (2) surrounds the planetary gear and connects the main and driven transmission shafts through the speed control disc and the drive wheel . See image 3 , a clutch chamber (9) is provided in the shaft hole of the planetary gear, and a self-locking pendulum pin (11) is provided in the chamber. The supporting point is the center of circle to swing. The length of the self-locking pendulum pin is greater than the radial distance between its supporting point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com