Roller-type step-less speed variator containing shear-like lever plate

A continuously variable transmission, lever plate technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve problems such as loss, chain tension drop, chain wear, etc., to extend service life, improve transmission power, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

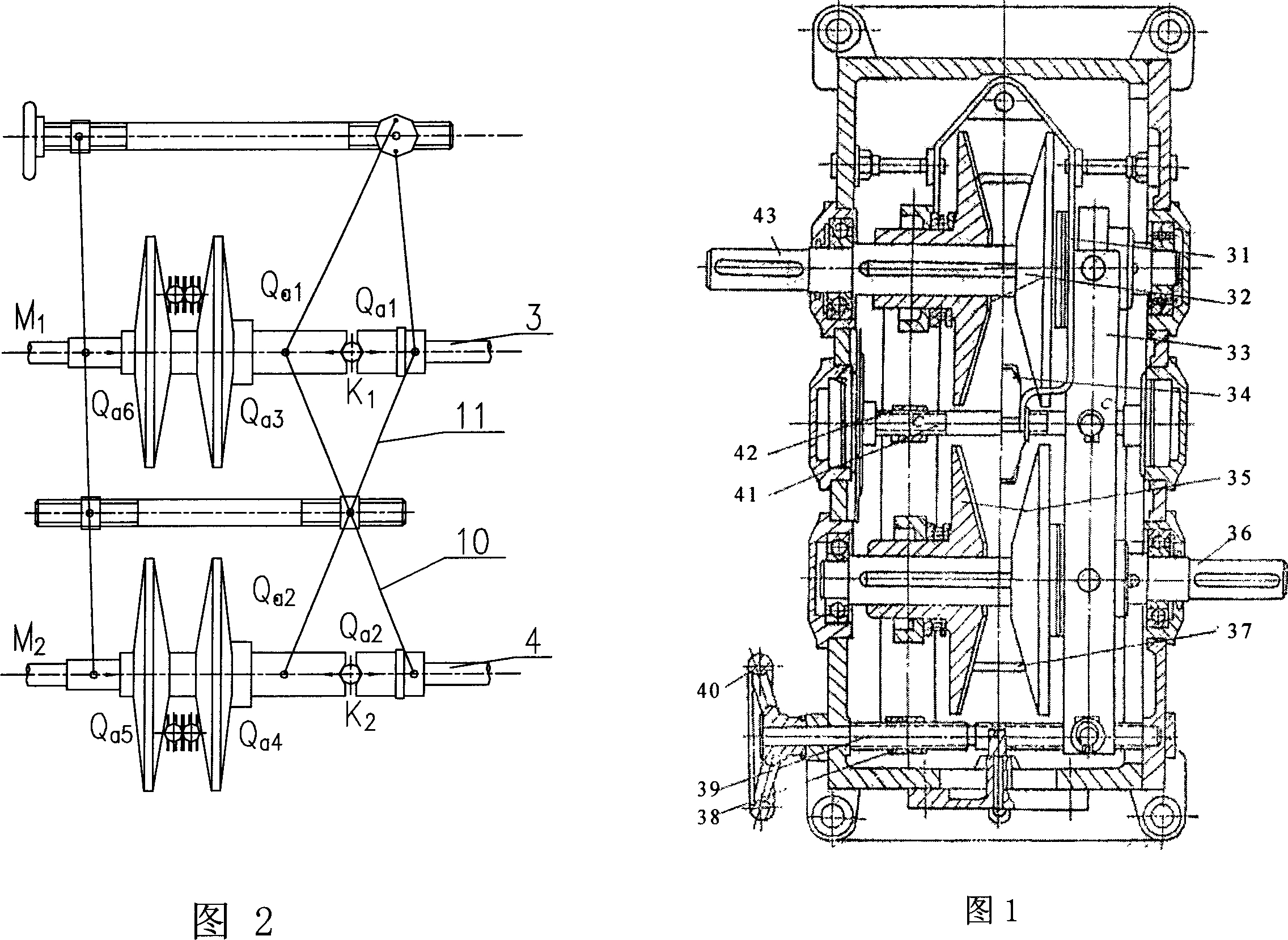

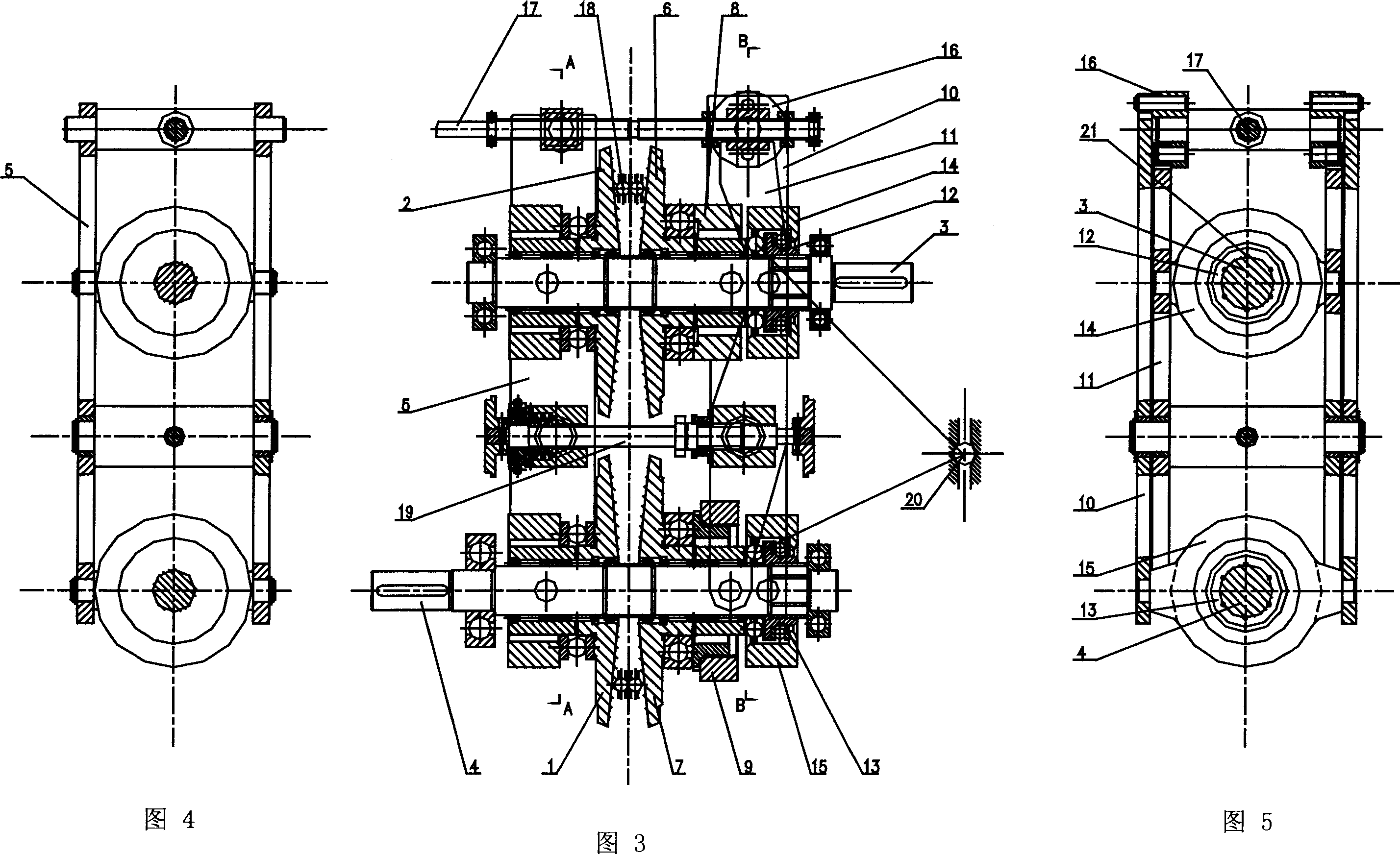

[0015] Referring to Fig. 3, Fig. 4 and Fig. 5, a roller-type continuously variable transmission with a scissor-shaped lever plate mainly includes two pairs of driving sprockets 2, 6, driven sprockets 1, 7, and Input shaft 3, output shaft 4, speed regulating lever, speed regulating screw mandrel 17, tensioning chain screw mandrel 19. The input shaft 3 and the output shaft 4 are installed in parallel, and a chain screw 19 is installed between the input shaft 3 and the output shaft 4, the driving sprocket 2, 6 is installed on the input shaft 3, and the driven sprocket 1, 7 is installed on the output shaft 4, a wedge-shaped clamping groove is formed between two relative sprocket surfaces 2,6 and 1,7, and a chain 18 is clamped as a transmission chain, and the transmission chain is a roller chain 18. One side of the input shaft 3 is equipped with a speed regulating screw mandrel 17 .

[0016] Speed regulating lever comprises single lever 5 and long, short scissors shape lever pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com