Ultralow-speed-ratio high-rigidity high-precision cycloidal-pin wheel planetary transmission speed reducer

A technology of cycloidal pinwheel and planetary transmission, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of poor overturning rigidity, lowering, and difficult reduction ratio of the whole machine, and achieve high transmission power and high efficiency , Improve the effect of torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] DRAWINGS Embodiments of the present invention will be described in detail, the present embodiments are premised aspect of the invention, it is given and the specific operation of the embodiment in detail, but the scope of the present invention is not limited to the following examples .

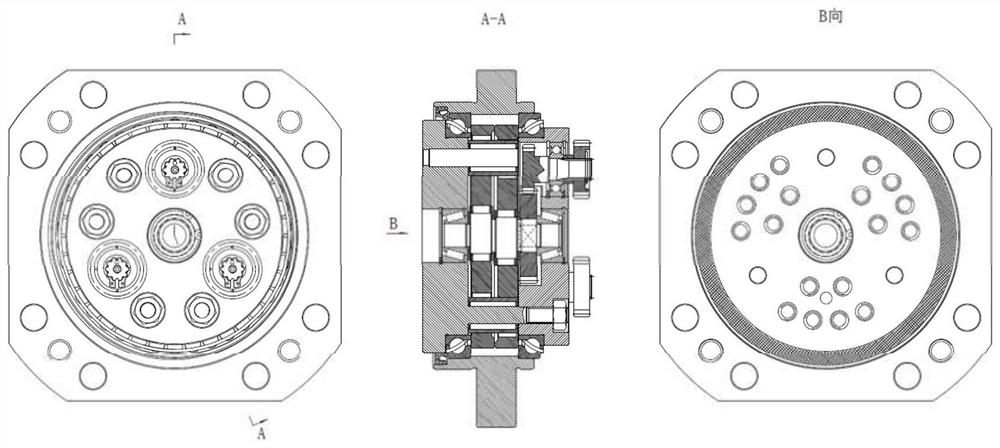

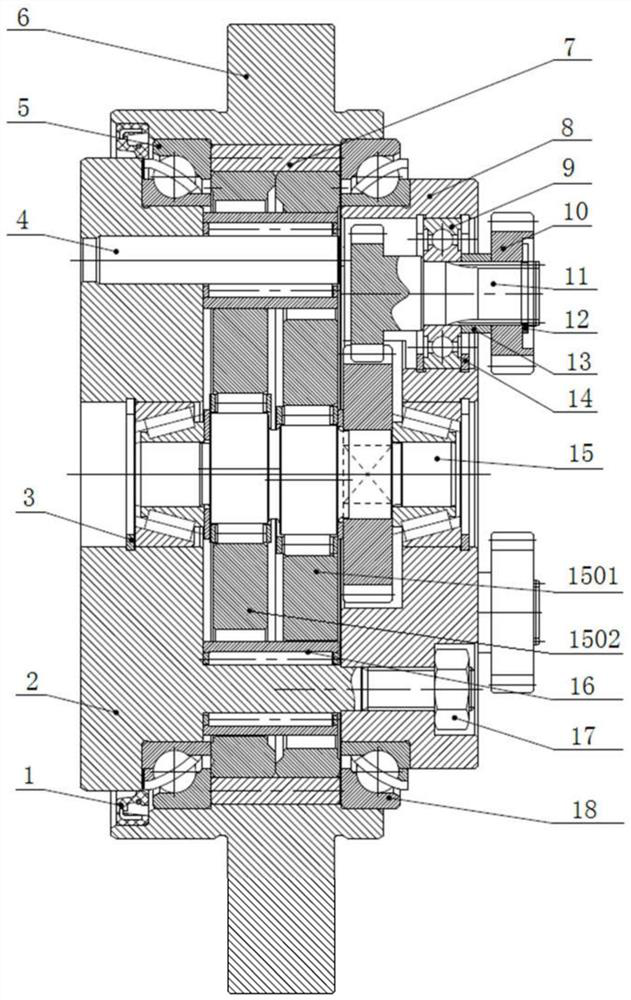

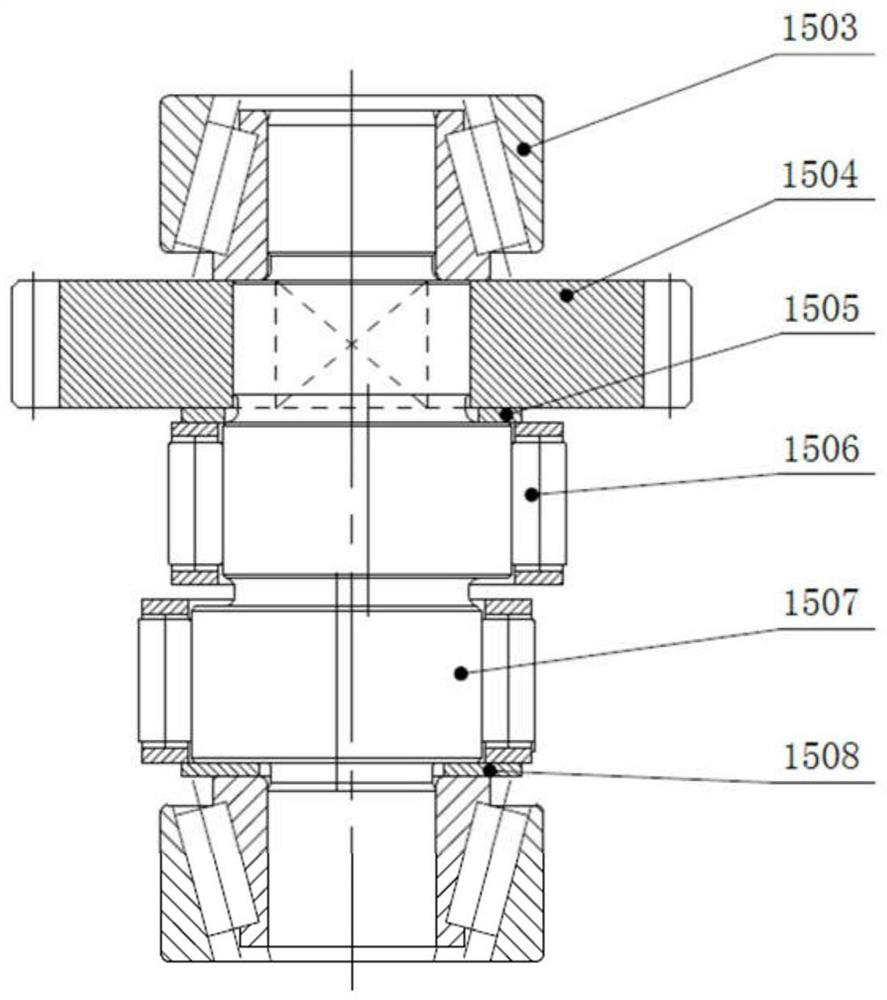

[0035] The present embodiment shows a structure in a compact, high-rigidity, cycloid planetary reducer with high accuracy, the first stage includes a high-speed overdrive ratio, a second low-speed reduction gear stage, the third stage low-speed "two teeth difference "cycloid drive ultra-low ratio. The present invention has a small size, long life, stable transmission, low noise, strong bearing capacity, while the transmission of high efficiency, but also has high precision. Cycloid as a whole which ensure high torsional stiffness, high transmission precision core parts, reasonable tooth design is particularly important.

[0036] like Figure 1-2 Shown, including a crank shaft gear reducer as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com