Vehicle body structure

A structure and body technology, applied in the direction of load-bearing body structure, upper structure, lower structure, etc., to achieve the effect of improving bending rigidity and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the form for implementing this invention is demonstrated based on drawing.

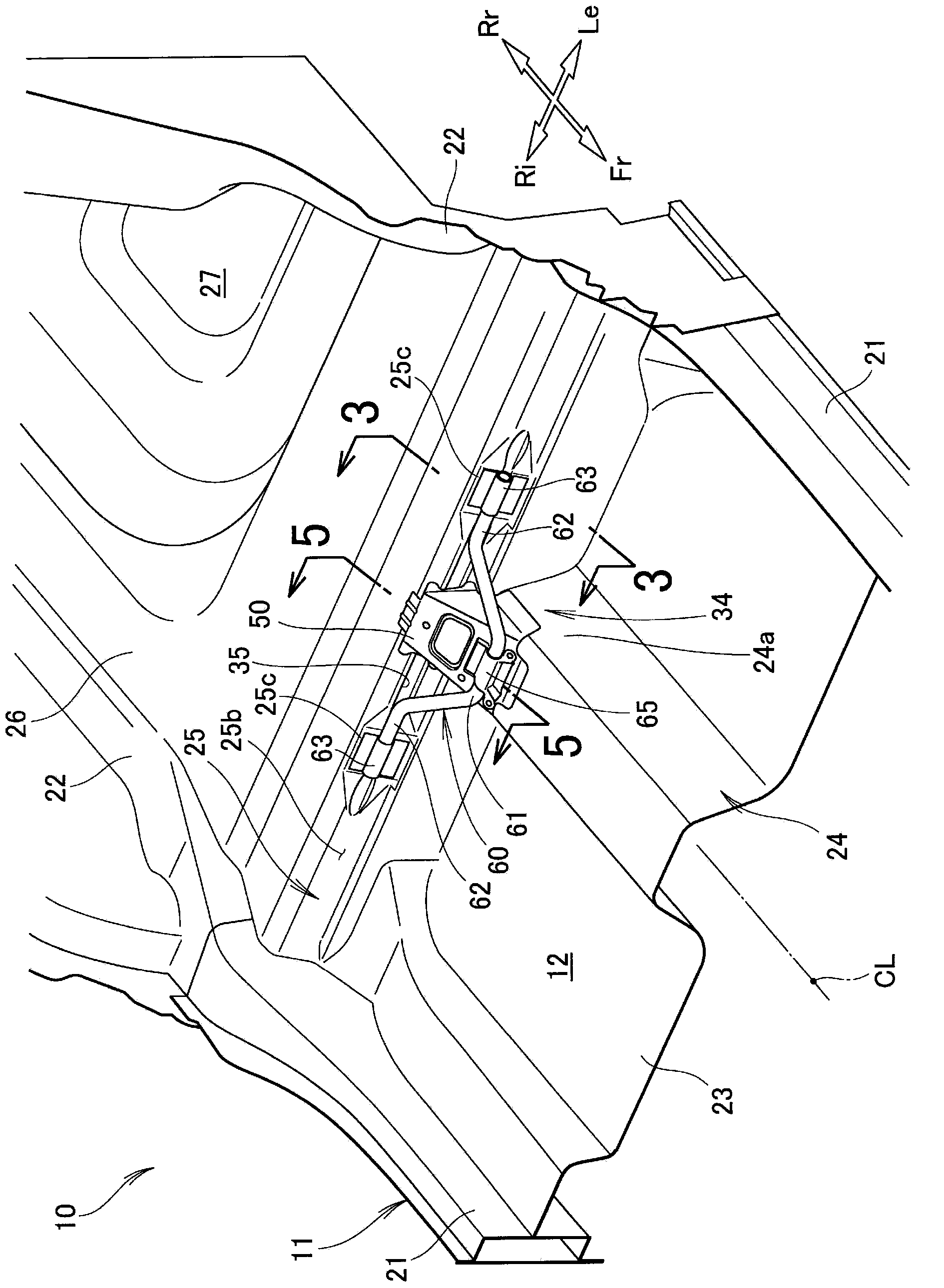

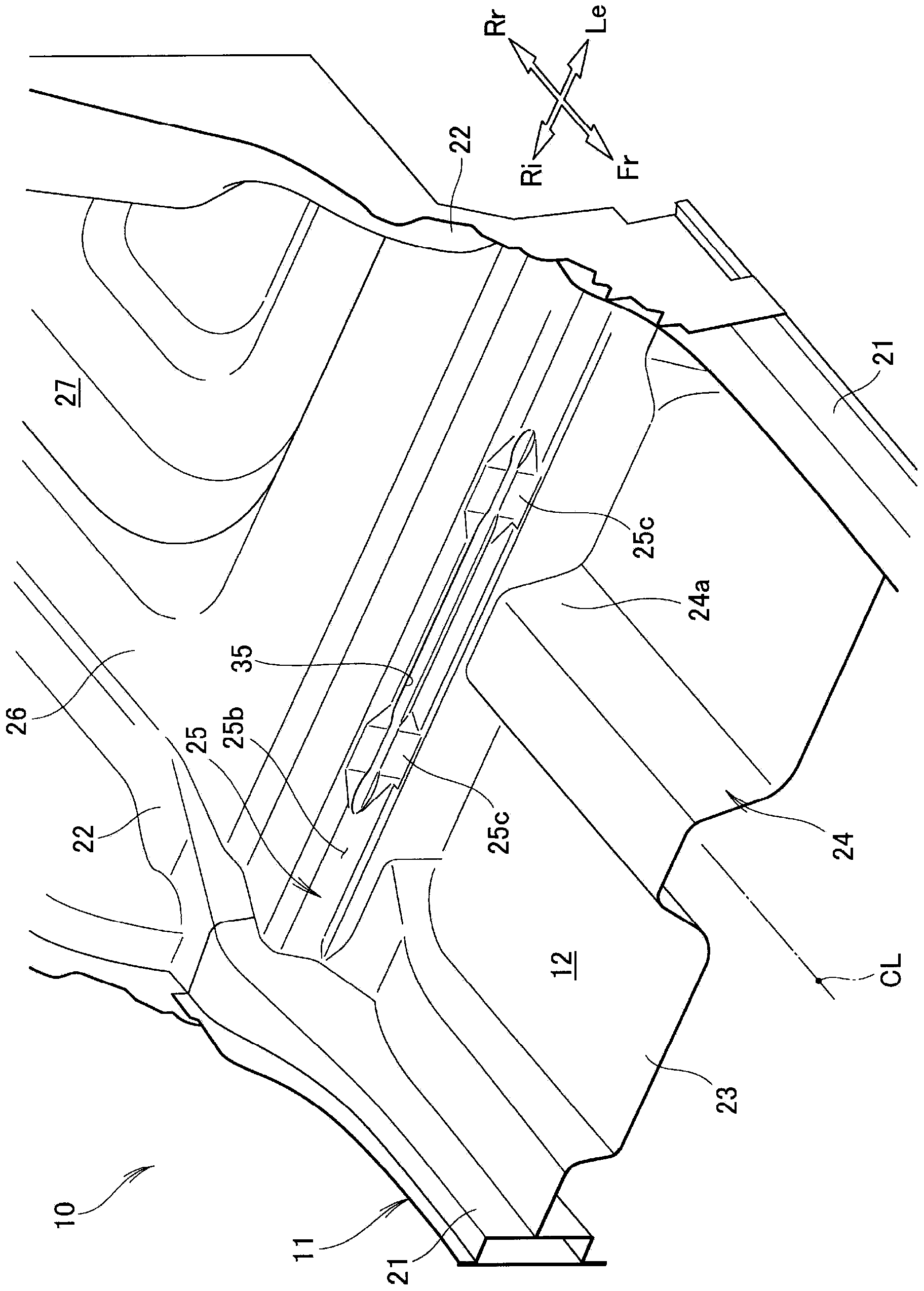

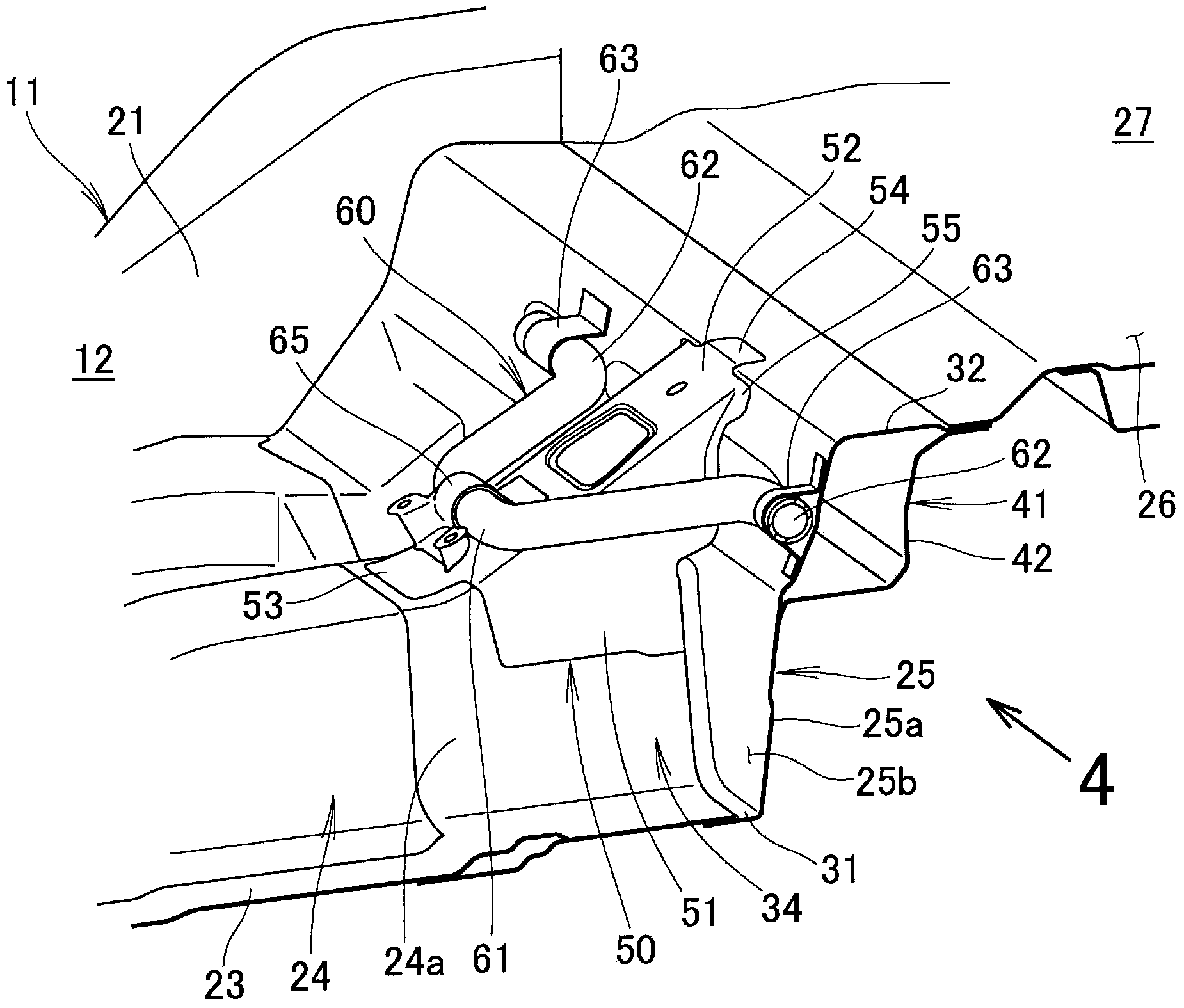

[0045] The vehicle body rear structure of the embodiment will be described based on the drawings. In addition, "front", "rear", "left", "right", "up", and "down" follow the direction viewed from the driver, and Fr indicates the front side, Rr indicates the rear side, Le indicates the left side, and Ri indicates On the right, CL represents the vehicle width centerline.

[0046] Such as figure 1 as well as figure 2 As shown, the vehicle body 11 of a vehicle 10 such as a passenger car is constituted by a monocoque body, and is substantially equal to the vehicle width centerline CL passing through the center of the vehicle 10 in the vehicle width direction and extending in the vehicle front-rear direction. Left and right symmetrical shape and form. The vehicle 10 has, for example, three rows of seats (front seats, center seats, and rear seats) in the cabin 12 , front and rear.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com