Bumper system for vehicle

A technology for bumpers and vehicles, applied in the field of bumper systems, which can solve the problems of high complexity of bumper systems and the impossibility of saving weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

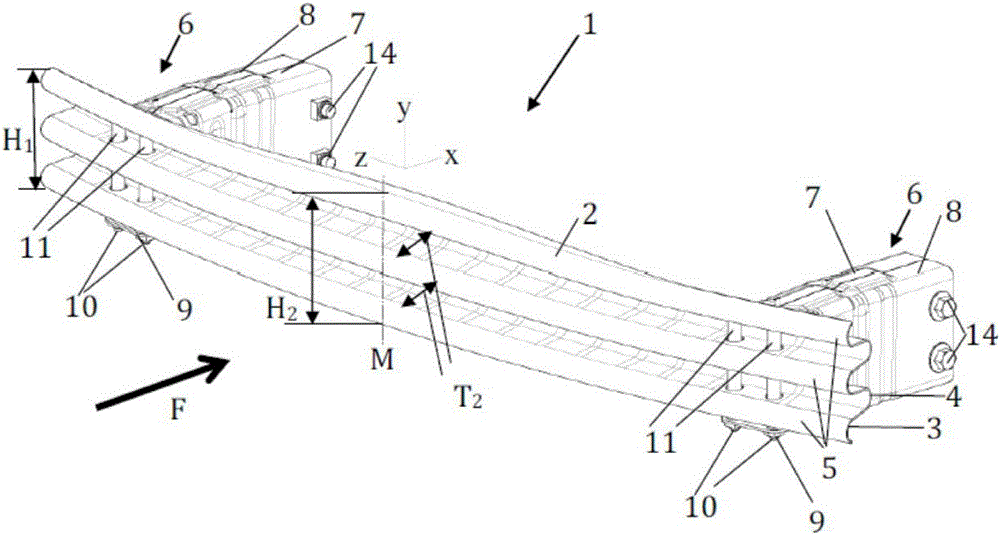

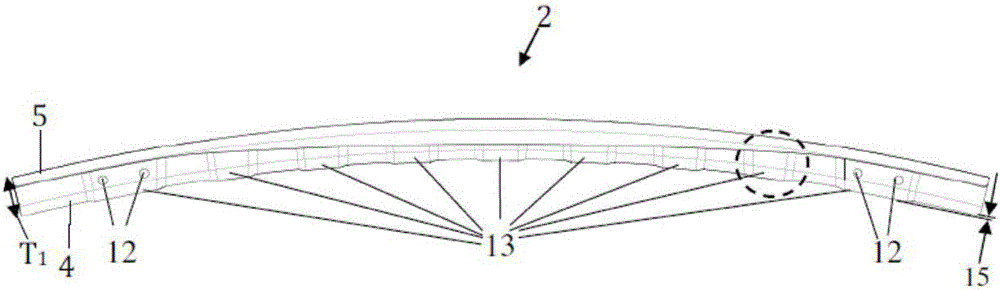

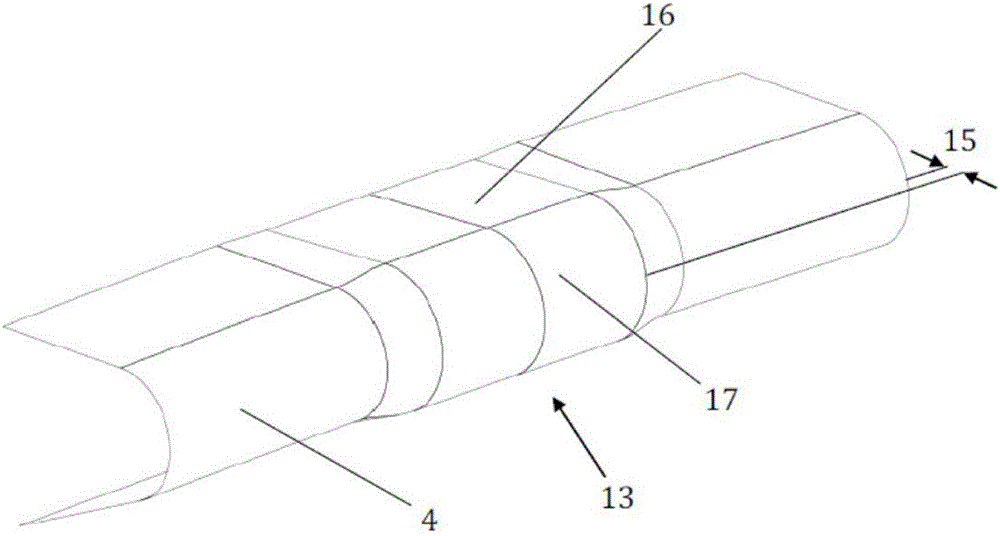

[0016] figure 1 An exemplary embodiment of the bumper system (1) according to the invention is shown in perspective. The bumper system comprises at least one bumper bracket (2) made of metallic material, in particular of high-strength steel material, preferably of hot-formed steel and correspondingly (press) hardened steel material, said bumper bracket has an undulating cross-section or body structure, wherein said undulating shape (3) is such that said bumper bracket (2) has at least one, in this case two undulating valleys (4) and at least two, in this case Below is an example of three undulating peaks (5). Furthermore, on the left-hand and right-hand sides of the bumper bracket (2), there are provided deformation elements (6) which can be connected to longitudinal beams (not shown) of the vehicle body by preferably detachable threaded connections (14). The deformation element (6) is assembled from eg at least two half-shells (7, 8), preferably formed of steel material and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com