Fuel injection valve and method for manufacturing fuel injection valve

A technology of fuel injection valve and manufacturing method, which is applied in the direction of fuel injection device, special fuel injection device, charging system, etc., to achieve the effect of easy strength, easy assurance, and suppressing the increase of magnetic path loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

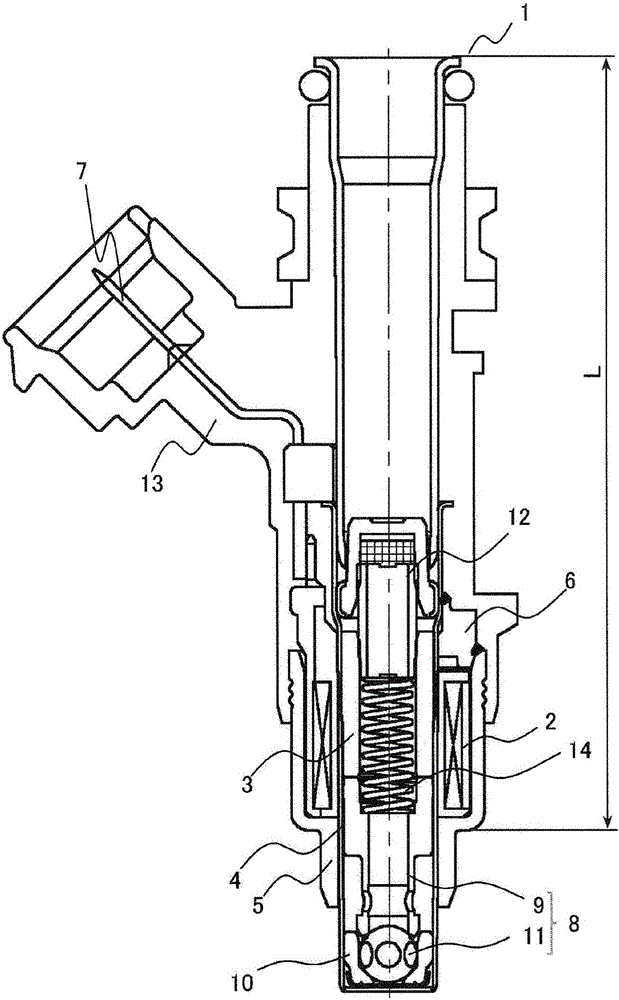

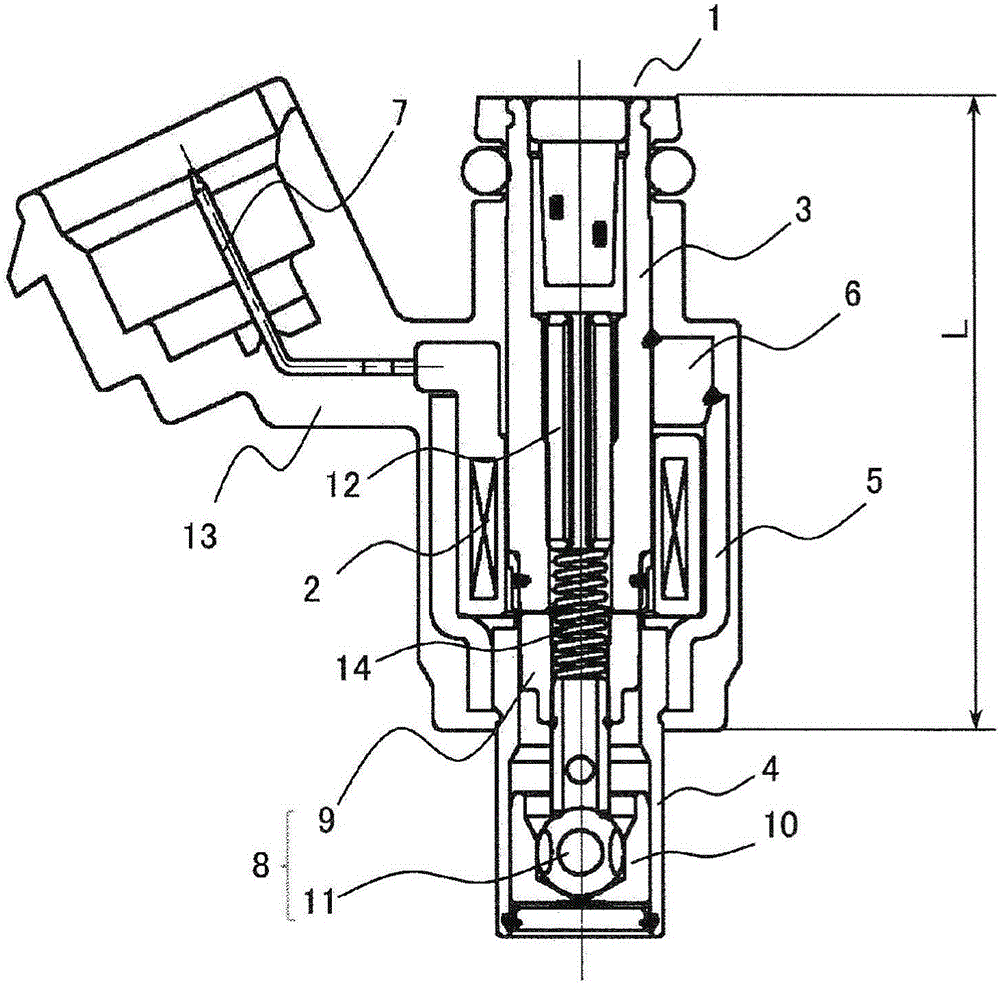

[0049] Next, the fuel injection valve according to Embodiment 1 of the present invention will be described. figure 2 It is a longitudinal sectional view of the fuel injection valve according to Embodiment 1 of the present invention. figure 2Among them, the fuel injection valve 1 includes: a metal casing 5 having an unequal cylindrical shape having a large diameter portion and a small diameter portion; 4. A hollow cylindrical solenoid 2 accommodated inside the large diameter portion of the housing 5; a hollow cylindrical core 3 penetrating the solenoid 2; The armature 9 is held by the bracket 4 so as to be able to move in the axial direction; the valve part 11 fixed to the armature 9; 10. The cover portion 6 that is disposed opposite to the outer peripheral surface of the core 3 and that is in pressure contact with the tapered surface of the opening of the housing 5 is fixed to the housing 5 by welding to cover the opening of the housing 5 in a cap shape; and disposing The ...

Embodiment approach 2

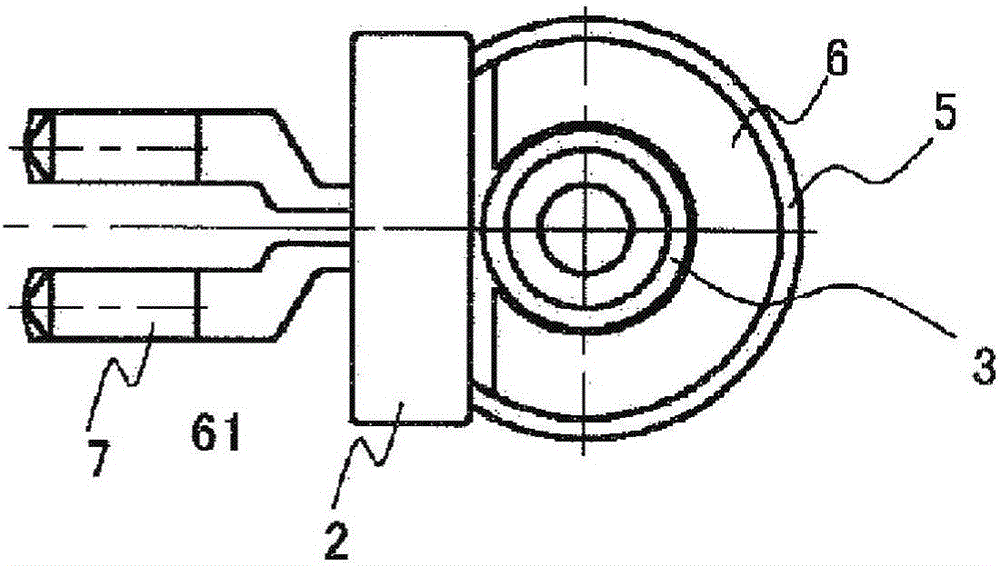

[0062] Next, a method of manufacturing the fuel injection valve according to Embodiment 2 of the present invention will be described. Figure 7 is used to describe one step in the method of manufacturing the fuel injection valve according to Embodiment 2 of the present invention, along Figure 4 Transverse sectional view of line A-A. Figure 7 In this process, the load P is applied by a jig, so that the central axis X2 of the cover part 6 faces the notch 61 of the cover part 6 with respect to the central axis X1 of the core 3 (refer to image 3 ) one side is eccentric until it is in contact with the iron core 3 or is about to contact the state, and the cover part 6 and the iron core 3 are fixed by welding. This step corresponds to the above-mentioned second step. At this time, the load P at which the coaxiality between the core 3 and the bracket 4 does not change is set as an upper limit to prevent poor mold insertion when the connector mold 13 is molded. In addition, since...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com