Rubber track and track type traveling body

一种橡胶履带、行驶体的技术,应用在橡胶履带及履带式行驶体领域,能够解决大剪切应变、龟裂、弯曲刚性差异等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

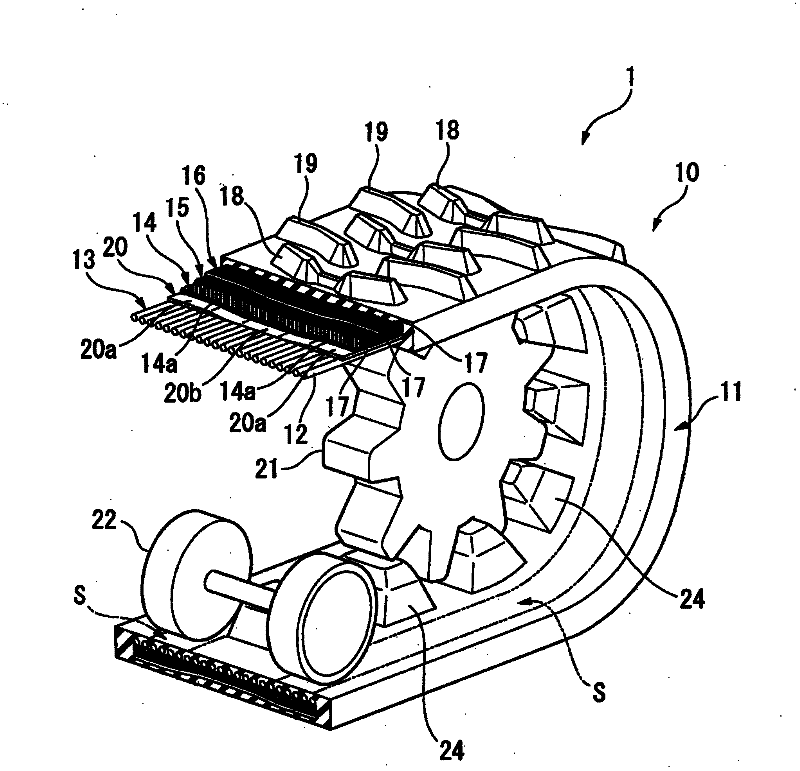

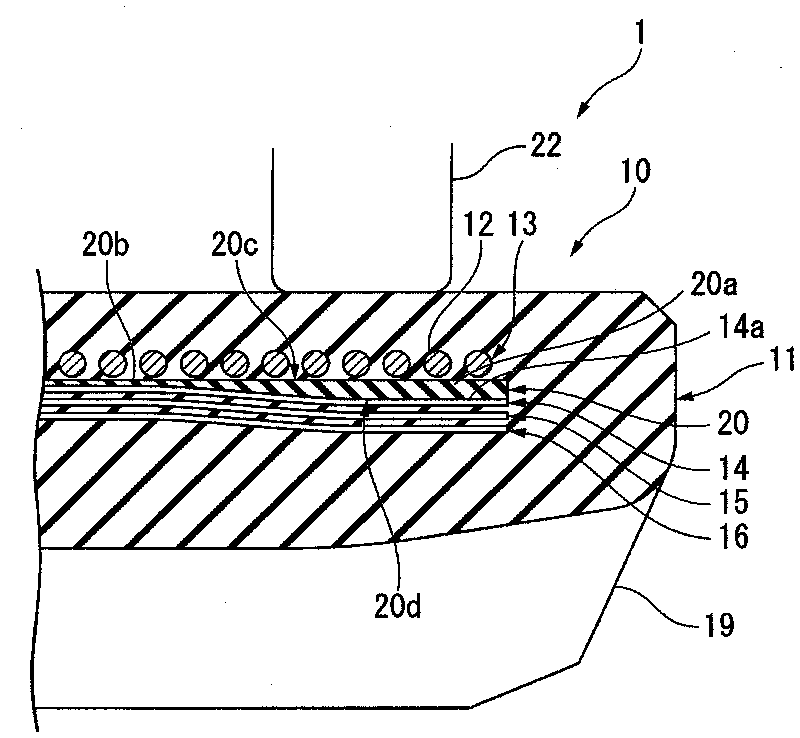

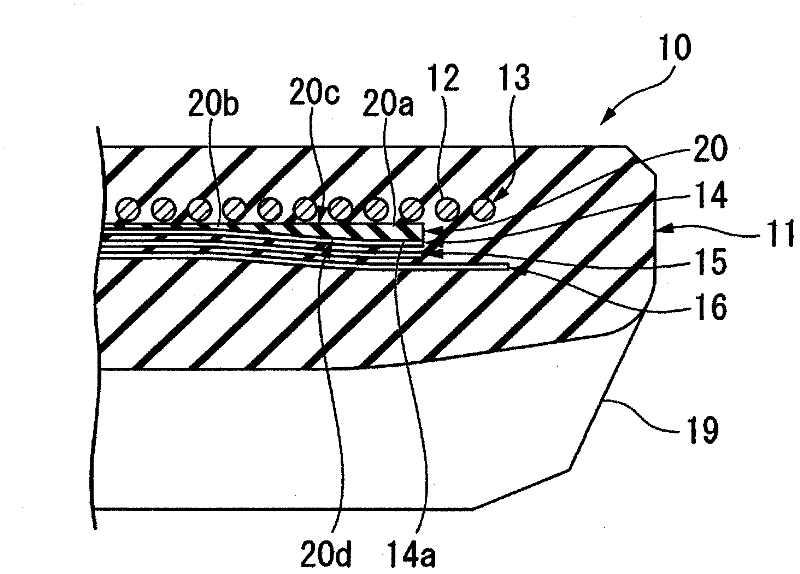

[0027] Below, refer to figure 1 and figure 2 One embodiment of the rubber crawler of the present invention will be described.

[0028] like figure 1 As shown, on the left and right pairs of crawler running bodies 1 disposed on the bottom of construction machinery such as hydraulic excavators, agricultural machinery, and other crawler vehicles, respectively, there are: driving wheels 21; driven wheels not shown in the figure; The rubber crawler 10 wound between the above two wheels in an endless belt shape; the pair of left and right roller passing surfaces S formed on the inner peripheral surface of the rubber crawler main body 11 of the rubber crawler 10 is arranged and along with the rubber crawler 10 The feeding movement of the rubber track 10 rolls a plurality of rollers 22 . In addition, in the illustrated example, the rubber crawler 10 is a so-called coreless rubber crawler in which a core is not embedded.

[0029] The driving wheel 21 is a sprocket, and is rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com