Improved planetary reducer

A planetary reducer and planetary gear technology, which is applied to components with teeth, portable lifting devices, transmission parts, etc., can solve the problems of poor accuracy retention, small single-stage reduction ratio, complex structure, etc. Stable accuracy, large reduction ratio range and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

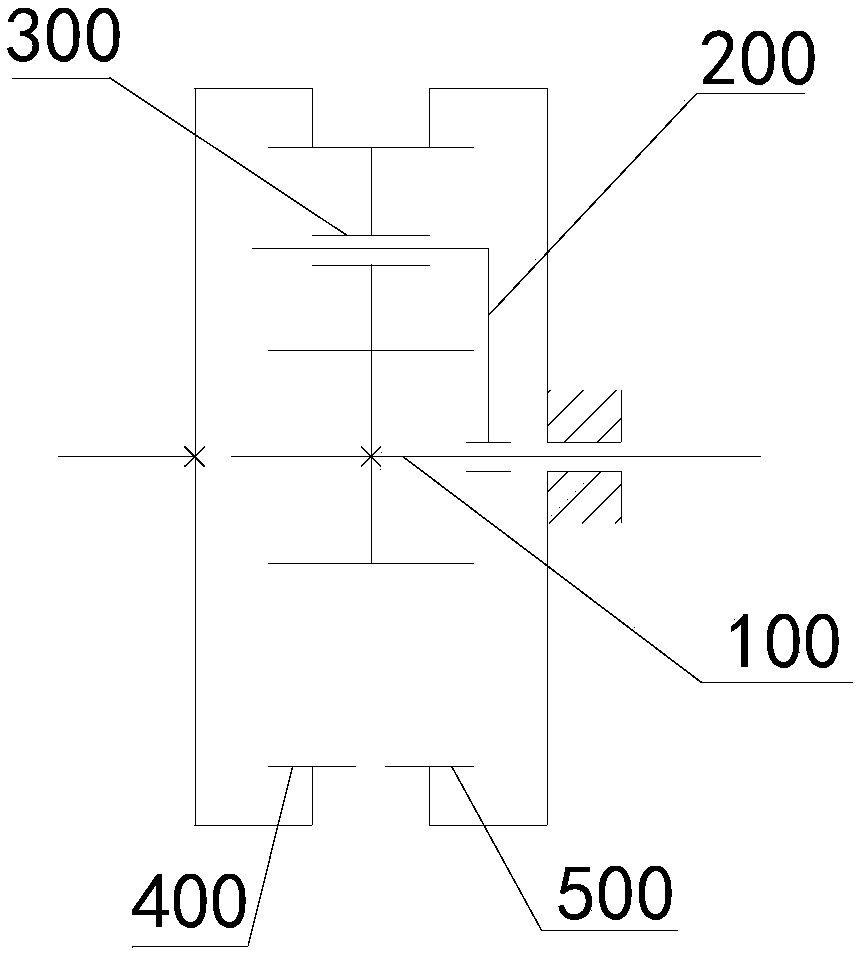

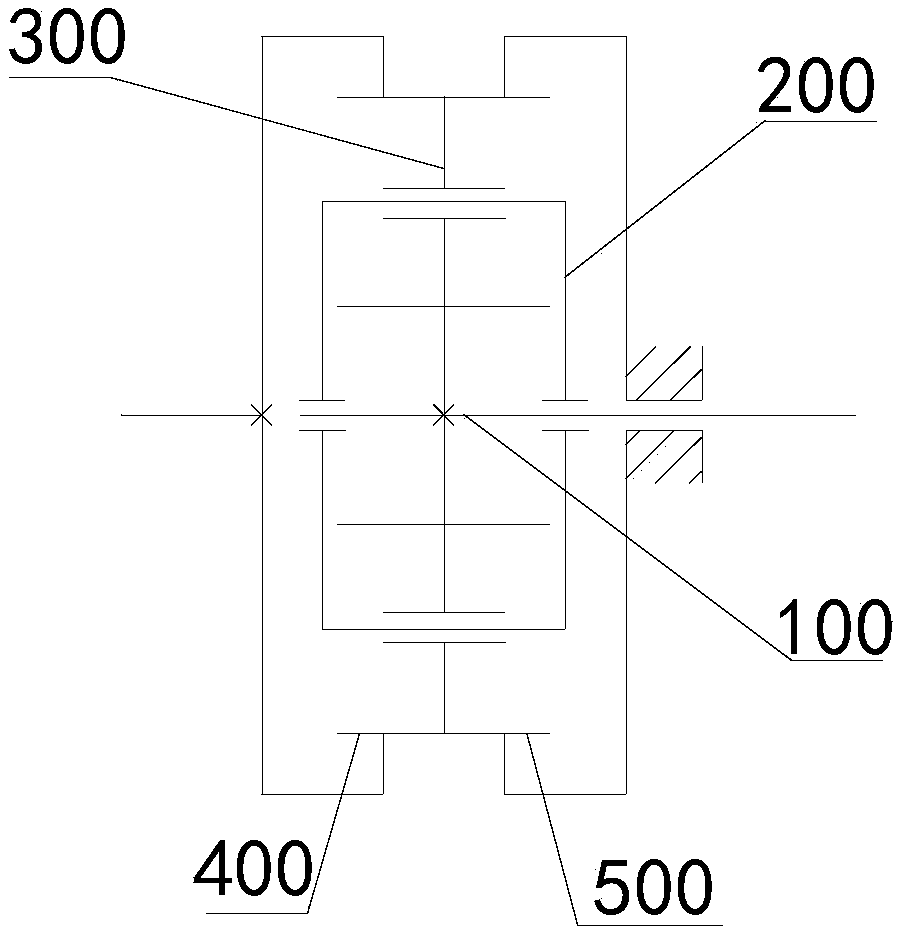

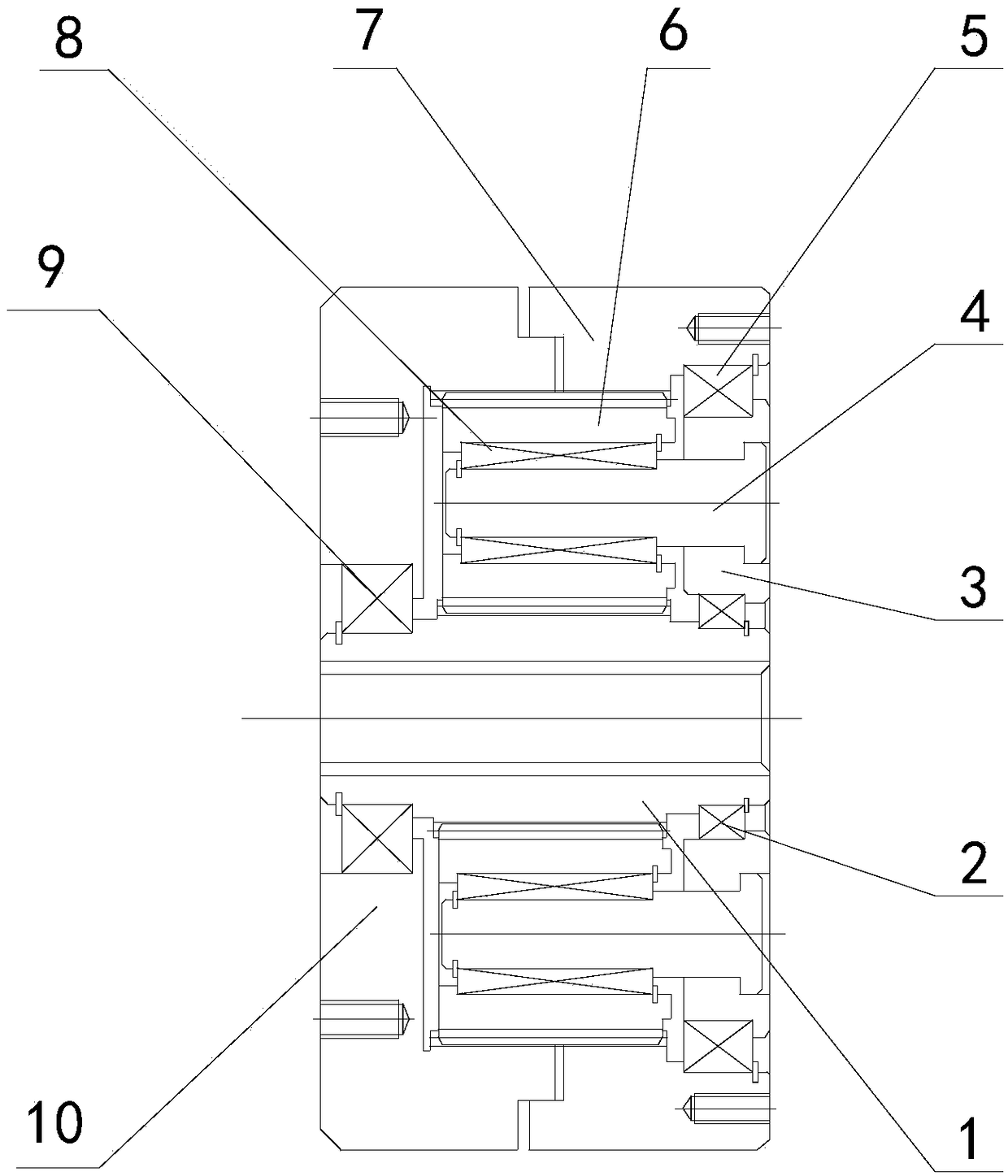

[0037] see image 3 , is a structural schematic diagram of an embodiment of the present invention, providing an improved planetary reducer, including a center wheel 1, a stationary wheel 7 arranged circumferentially along one end of the center wheel 1, and at least A planetary mechanism, and the output wheel 10 that is arranged on the other end of the center wheel 1, the planetary mechanism includes a planetary carrier 3 that is rotated on the stationary wheel 7, a planetary shaft 4 that is arranged on the plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com