Coupling Structure Between Front Pillar And Side Sill Of Automobile

一种前支柱、结合部的技术,应用在上部结构、车辆部件、上部结构分总成等方向,能够解决加工困难、生产率恶化等问题,达到高生产率、提高抗扭刚性、提高操纵稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

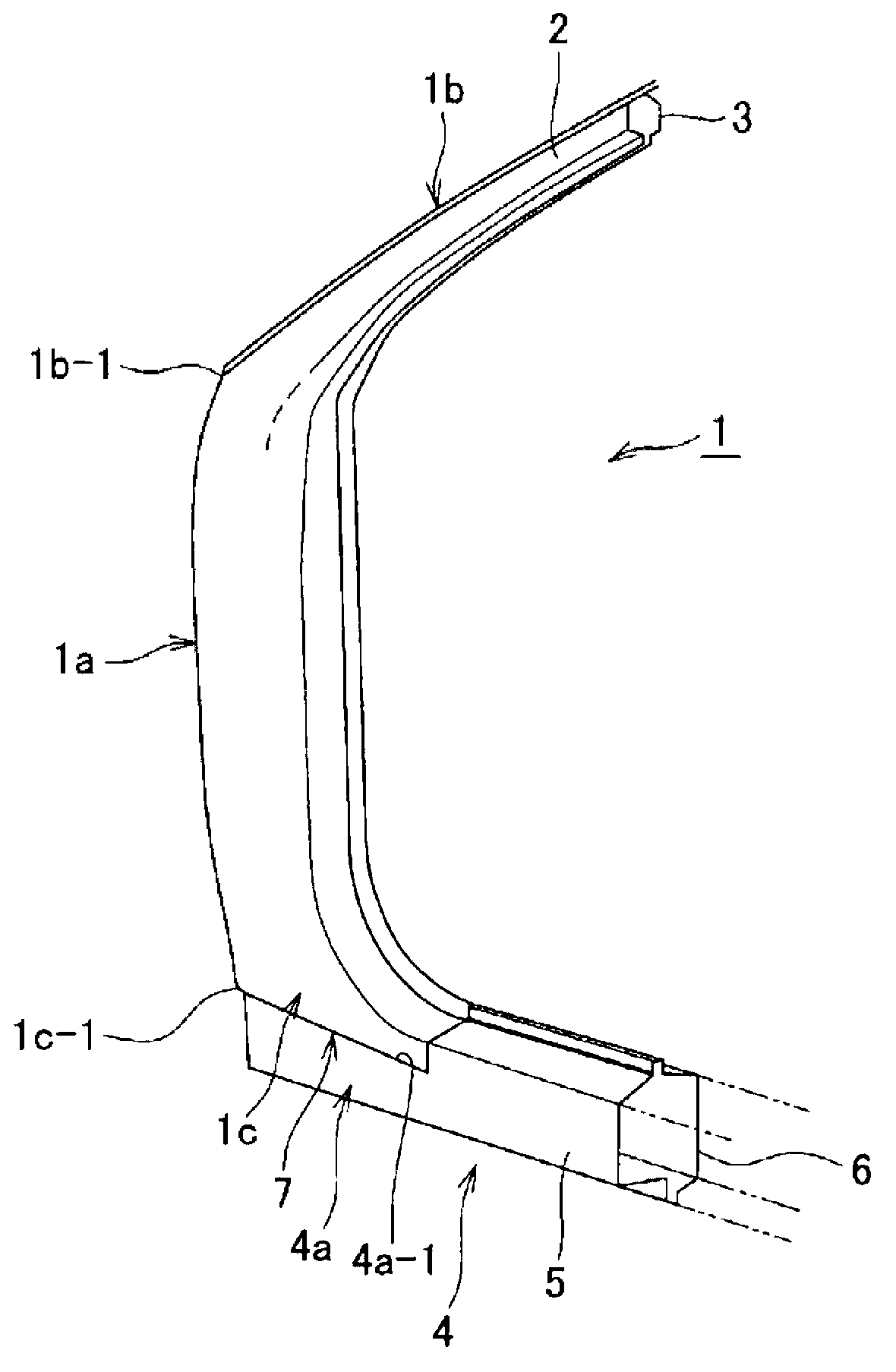

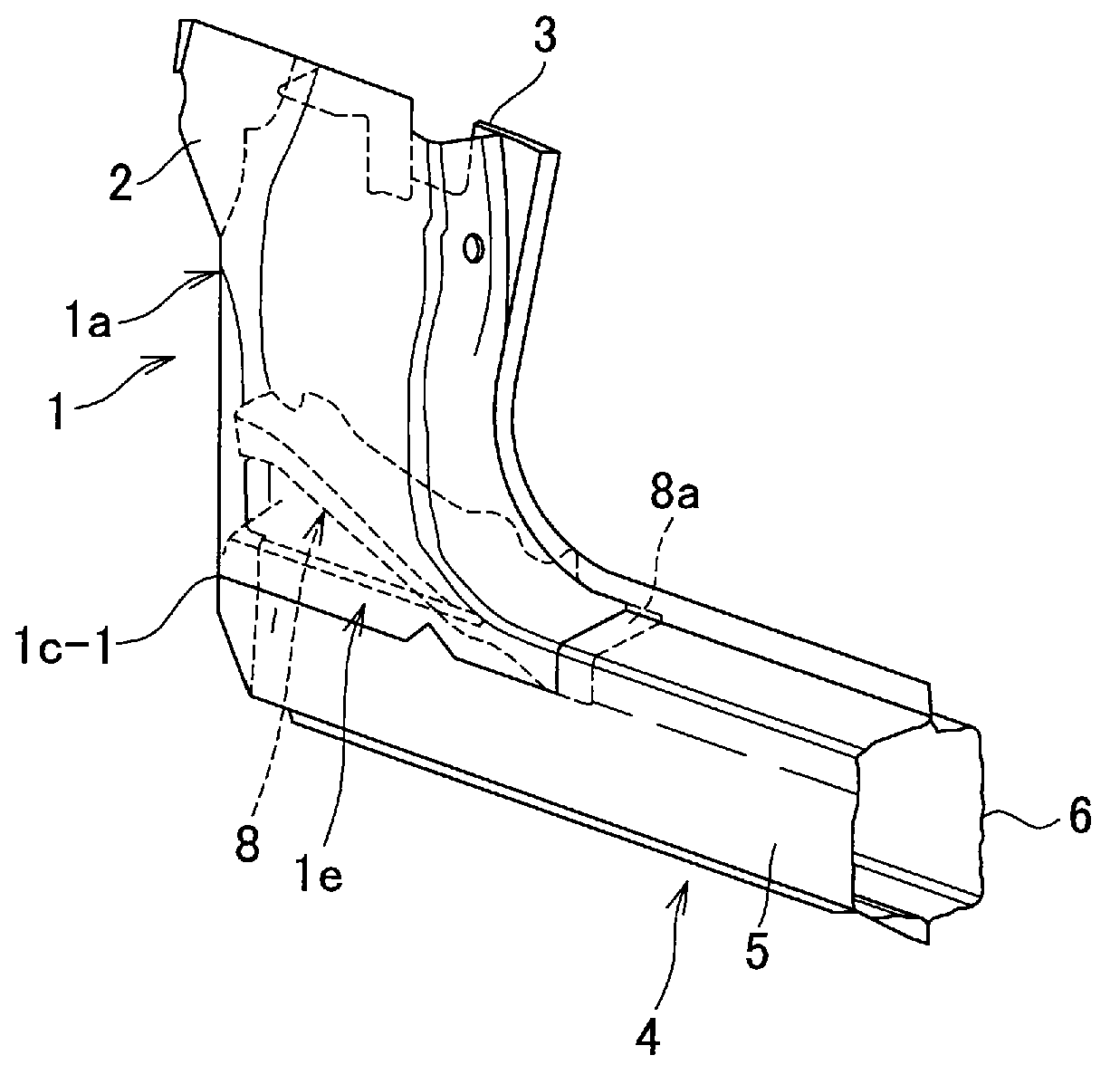

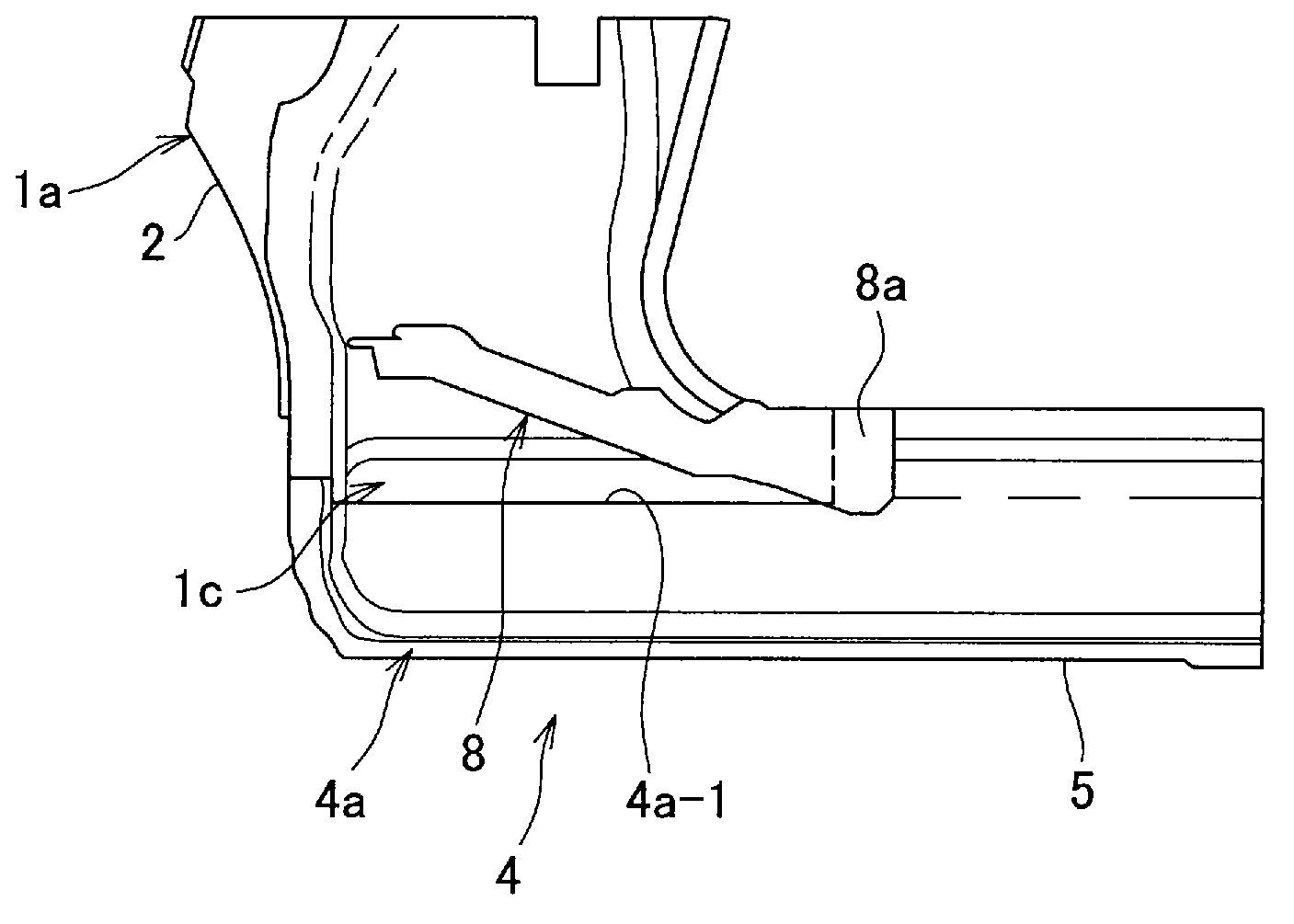

[0055] Such as figure 1 As shown, the front pillar 1 according to an embodiment of the present invention is extended in the vertical direction of the automobile, and the front pillar outer panel 2 with a cross-sectional hat shape formed by using a material such as a steel plate with high material strength and combining the material strength The end flanges of the front pillar inner panel 3 in a state in which a material such as a steel plate that is not too high is formed in a state where relatively many flat portions are formed form a closed cross-sectional shape.

[0056] The front pillar 1 takes the center portion 1a as the center, and its upper end portion 1b and lower end portion 1c have bent portions 1b-1, 1c-1, and extends toward the rear of the vehicle. Both the front pillar outer panel 2 and the front pillar inner panel 3 can be A single structure formed by, for example, stamping.

[0057] In addition, the lower end portion 1c of the front pillar 1 is opened downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com