Chain drive screening pulverizer

A technology of chain drive and grinding machine, which is applied in the field of sieving grinding equipment, can solve the problems that the transmission ratio cannot be kept strictly unchanged, it is not suitable for transmission with a large distance, and the transmission efficiency of belt transmission is low, and the pressure is small. , Easy maintenance, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

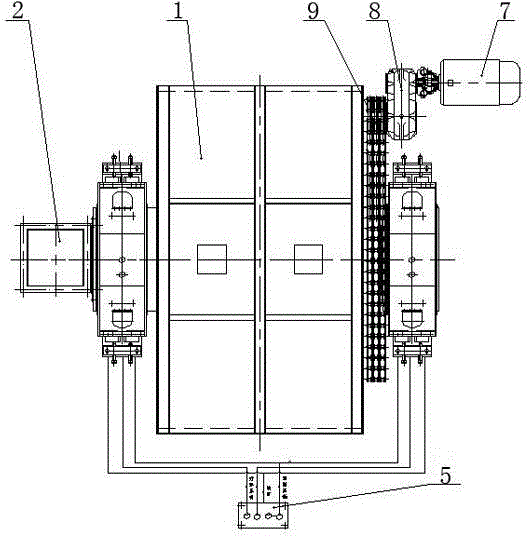

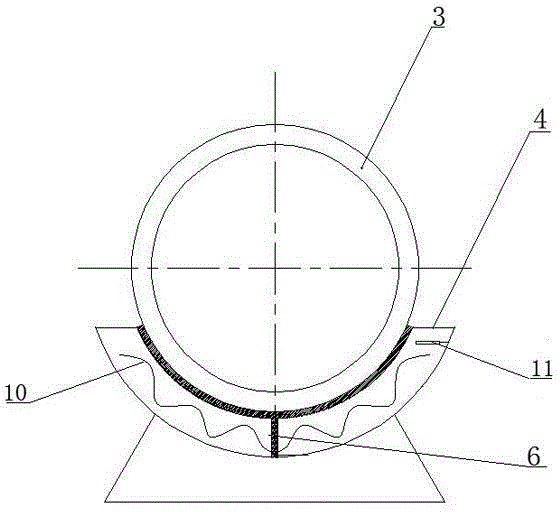

[0015] As shown in the figure: a chain drive screening type pulverizer, including a cylinder body 1, a feeding mechanism 2, a material discharging mechanism, a hollow shaft 3, a hollow shaft supporting mechanism and a transmission mechanism, the two ends of the cylinder body 1 An end cover is provided, and the hollow shaft 3 is installed in the cylinder body 1, and the two ends of the hollow shaft 3 protrude from the end cover respectively, and the two protruding ends of the hollow shaft 3 are supported by a supporting mechanism, and the supporting mechanism It includes a dynamic and static pressure main bearing 4 and a high and low pressure lubrication station 5. The dynamic and static pressure main bearing 4 has a supporting arc surface that cooperates with the hollow shaft 3. The dynamic and static pressure main bearing 4 is made of cast iron. The supporting arc surface of the dynamic and static pressure main bearing 4 A tile lining made of tin-based bearing alloy is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com