Preparation method and application of copper-copper bonding material

A bonding material, copper-copper bonding technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. Thermodynamic properties, the effect of reducing production equipment requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

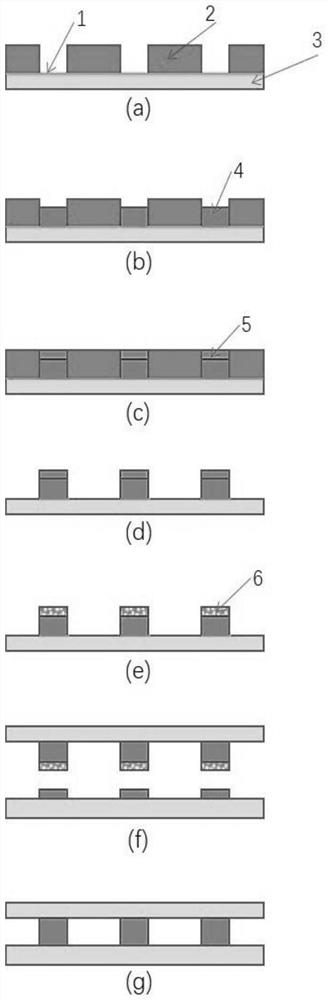

[0042] The preparation method of the copper-copper bonding material according to the embodiment of the present invention comprises the following steps:

[0043]Step S1, setting a nanoporous copper foam layer on the surface to be welded of at least one object to be welded;

[0044] In step S2, the surfaces to be welded of the object to be welded are arranged opposite to each other, and thermocompression bonding is performed to realize copper-copper bonding between the objects on both sides to be welded, and the copper-copper bonding material is obtained.

[0045] That is to say, according to the preparation method of the copper-copper bonding material of the embodiment of the present invention, a nanoporous copper foam layer is first arranged on at least one surface to be welded, and then the nanoporous copper foam layer is opposite to the surface to be welded on the other side. , to achieve copper-copper bonding by thermocompression bonding.

[0046] According to the preparat...

Embodiment 1

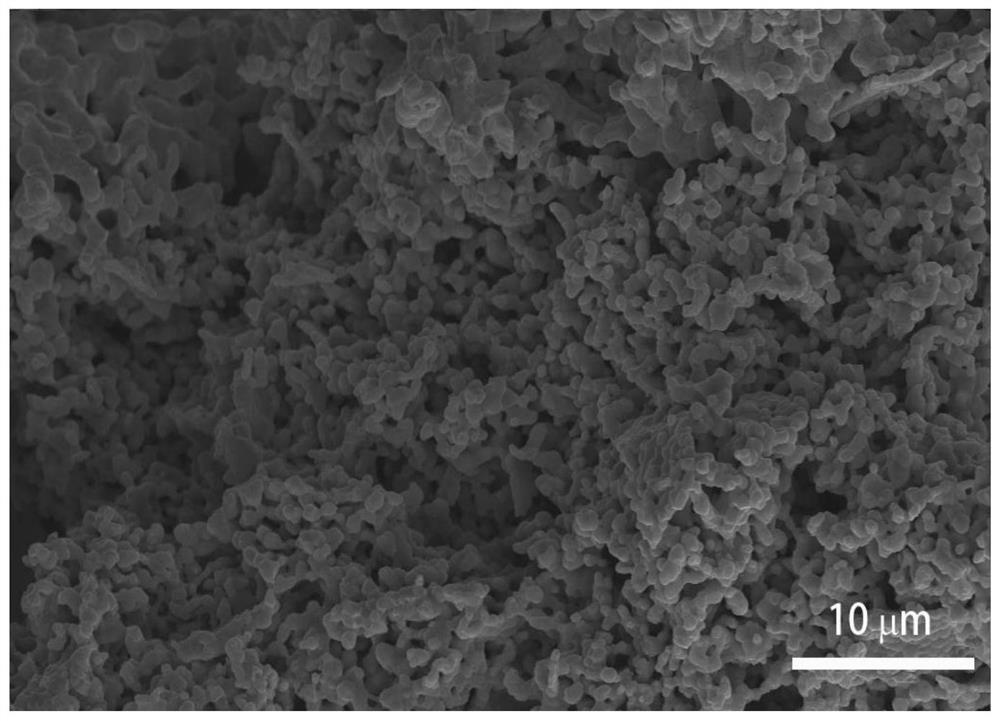

[0080] According to 0.0025mol / L copper sulfate CuSO 4 ·5H 2 O, 0.15mol / L zinc sulfate ZnSO 4 , 0.35mol / L potassium pyrophosphate K 4 P 2 o 7 , each reagent was weighed and added into pure water, stirred thoroughly and then dissolved, after which the pH value was adjusted to 7 by concentrated sulfuric acid to obtain an electroplating solution.

[0081] Thereafter, as the sample to be plated will be as figure 1 The silicon wafer shown in (a) that has completed the exposure and development process is placed in the electroplating solution, and a platinum anode is placed in the electroplating solution, and 0.2ASD is used for electroplating for 180 minutes to obtain a copper-zinc alloy layer. After that, take out the electroplated silicon wafer, remove the photoresist layer, wash the surface with pure water, dry it with cold air, and bake it at 200°C for 15 minutes under the protection of nitrogen to reform the copper-zinc alloy coating.

[0082] Then, the silicon wafer is put...

Embodiment 2

[0089] According to 0.0045mol / L copper sulfate CuSO 4 ·5H 2 O, 0.3mol / L zinc sulfate ZnSO 4 , 0.5mol / L potassium pyrophosphate K 4 P 2 o 7 , each reagent was weighed and added into pure water, stirred thoroughly and then dissolved, after which the pH value was adjusted to 8 by concentrated sulfuric acid to obtain an electroplating solution.

[0090] Thereafter, the same silicon wafer as in Example 1 was placed in the electroplating solution, and a platinum anode was placed in the electroplating solution, and 0.5ASD was used for electroplating for 90 minutes to obtain a copper-zinc alloy layer. After that, take out the electroplated silicon wafer, remove the photoresist layer, wash the surface with pure water, dry it with cold air, and bake it at 180°C for 30 minutes under the protection of nitrogen to reform the crystal grains in the copper-zinc alloy coating.

[0091] Then, the wafer is placed in a dealloying solution to remove the zinc from the alloy. The dealloying so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com