Preparation method of carbon nano tube-reinforced aluminum base composite material

A carbon nanotube and aluminum-based technology, applied in the field of aluminum-based composite materials, can solve the problems of high process parameter requirements, complicated process operation, and carbon nanotubes are not easy to embed, so as to avoid difficult sintering, tensile strength and wear resistance. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

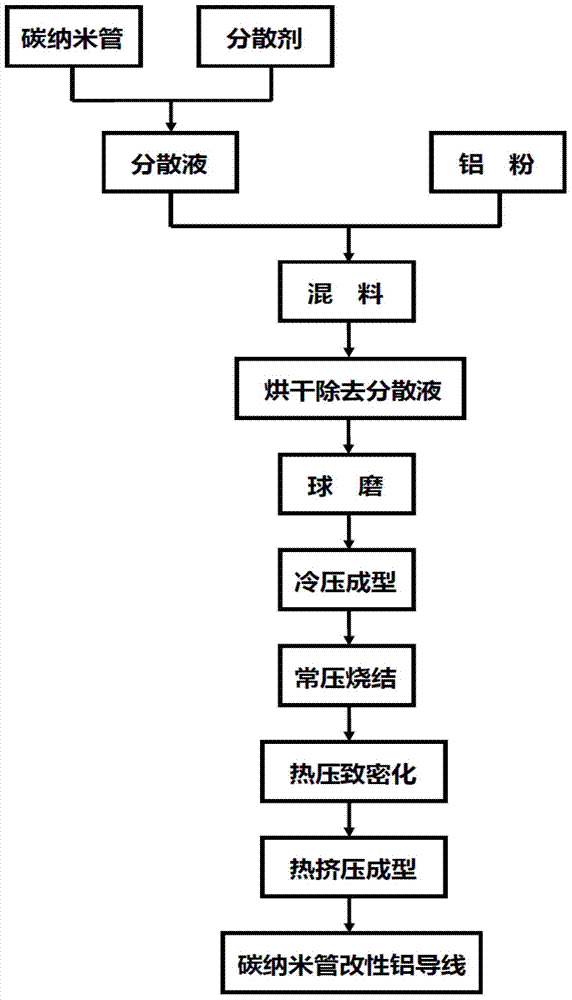

[0030] like figure 1 As shown, the preparation method of carbon nanotube-reinforced aluminum matrix composites is as follows:

[0031] 1) The carbon nanotubes are uniformly dispersed in N-methylpyrrolidone by ultrasonic vibration, and polyvinylidene fluoride is added and mixed to obtain a carbon nanotube dispersion liquid. The weight percentage of carbon nanotubes in the carbon nanotube dispersion liquid is 10%. The weight ratio of vinylidene fluoride to carbon nanotubes is 4:1;

[0032] 2) Mix the carbon nanotube dispersion with the pure aluminum powder evenly, then dry at 150 °C for 3 hours under vacuum conditions to volatilize the N-methylpyrrolidone to obtain a mixture. The weight of the carbon nanotubes in the mixture accounts for the pure aluminum powder. 10% by weight;

[0033] 3) Under the protection of inert gas, the mixture is ball-milled at 500rpm for 3h, the ratio of ball to material is 10:1, and the carbon nanotubes are completely embedded in the inside of the a...

Embodiment 2

[0036] 1) The carbon nanotubes are uniformly dispersed in toluene by ultrasonic vibration to obtain a carbon nanotube dispersion liquid, and the weight percentage of carbon nanotubes in the carbon nanotube dispersion liquid is 1%;

[0037] 2) Mix the carbon nanotube dispersion with the pure aluminum powder evenly, then dry at 150°C for 3 hours under vacuum conditions to volatilize the toluene to obtain a mixture, and the weight of the carbon nanotubes in the mixture accounts for 1% of the weight of the pure aluminum powder;

[0038] 3) Under the protection of inert gas, the mixture is ball-milled at 600rpm for 2h, the ratio of ball to material is 10:1, and the carbon nanotubes are completely embedded in the inside of the aluminum powder particles, so that the aluminum powder particles are exposed to the fresh surface;

[0039] 4) The ball-milled mixture is successively processed by cold pressing at a pressing pressure of 300 MPa, normal pressure sintering at 550 °C, hot-pressin...

Embodiment 3

[0041] 1) Disperse carbon nanotubes uniformly in ethanol by ultrasonic vibration, add sodium dodecyl sulfate and mix to obtain carbon nanotube dispersion liquid, the weight percentage of carbon nanotubes in carbon nanotube dispersion liquid is 8%, dodecane The weight ratio of sodium sulfate and carbon nanotubes is 3:1;

[0042] 2) Mix the carbon nanotube dispersion liquid with the pure aluminum powder evenly, and then dry it at 120°C for 4 hours under vacuum conditions to volatilize the ethanol to obtain a mixture. The weight of the carbon nanotubes in the mixture accounts for 8% of the weight of the pure aluminum powder;

[0043] 3) Under the protection of inert gas, the mixture is ball-milled at 500rpm for 6h, the ratio of ball to material is 15:1, and the carbon nanotubes are completely embedded in the inside of the aluminum powder particles, so that the aluminum powder particles are exposed to the fresh surface;

[0044]4) The ball-milled mixture is successively processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com