Method for testing rotary valve pneumatic actuator

A pneumatic actuator and testing method technology, applied in the testing of machine/structural components, testing of mechanical components, using stable tension/pressure to test the strength of materials, etc., can solve the problem of testing methods for pneumatic actuators that do not have rotary valves , The quality of the valve pneumatic actuator cannot be guaranteed, and the force value cannot meet the specified requirements, etc., to achieve the effect of small pressure, convenient testing, and accurate average transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

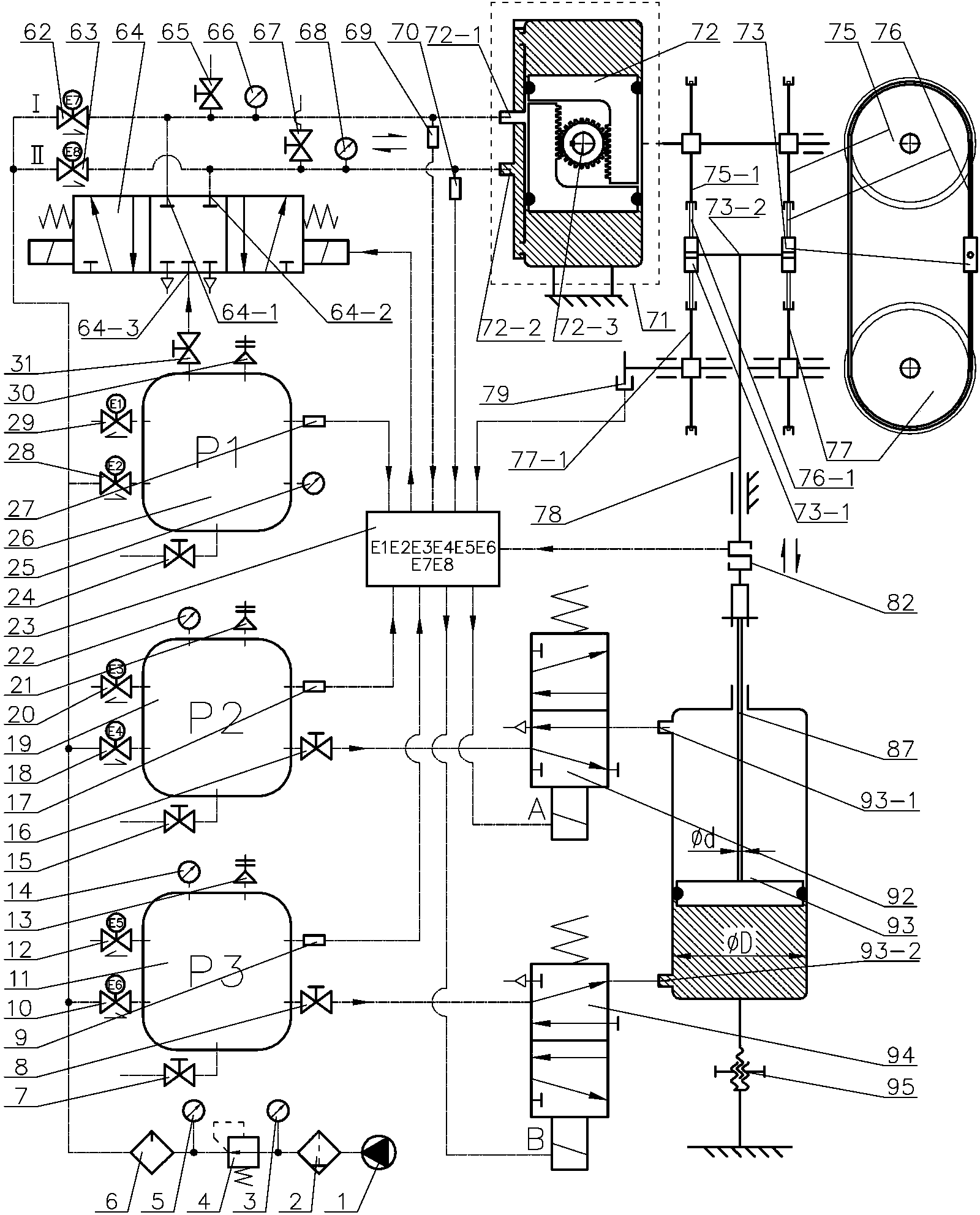

[0065] use as figure 1 The test device shown is used for no-load test, sealing test, strength test, load test and action life test of double-acting rotary valve pneumatic actuators.

[0066] The test device includes a first gas storage tank 26, a second gas storage tank 19, a third gas storage tank 11, a three-position five-way double-control solenoid valve 64, a first two-position five-way single-control solenoid valve 92, a second two-way Five-position single-control solenoid valve 94, automatic control system 23, double-acting rotary valve pneumatic actuator 72, back pressure cylinder 93, air source 1, water separation filter 2, inlet pressure gauge 3, pressure reducing valve 4, Outlet pressure gauge 5, lubricator 6, first high pressure solenoid valve 62, first high pressure exhaust valve 65, first high pressure gauge 66, second high pressure solenoid valve 63, second high pressure exhaust valve 67 and second high pressure pressure gauge 68,

[0067] The double-acting rot...

Embodiment 2

[0113] refer to figure 1 As shown in the test device of the first embodiment, the no-load test, sealing test, strength test, load test and action life test are carried out on the single-acting rotary valve pneumatic actuator.

[0114] The testing device in embodiment two is identical with the testing device in embodiment one in that:

[0115] Including air source 1, water separation filter 2, inlet pressure gauge 3, pressure reducing valve 4, outlet pressure gauge 5, lubricator 6, exhaust valve of the third air storage tank 7, air supply valve of the third air storage tank 8. The third gas storage tank pressure sensor 9, the third gas storage tank pressurization solenoid valve 10, the third gas storage tank 11, the third gas storage tank pressure relief solenoid valve 12, the third gas storage tank safety valve 13, the third gas storage tank Three gas tank pressure gauges 14, the second gas tank exhaust valve 15, the second gas tank supply valve 16, the second gas tank pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com